Content

If the farm has a walk-behind tractor or a motor-cultivator, the owner tries to use the equipment to the maximum at any time of the year. For example, in winter the unit can quickly clear a large area of snow. But to perform this work, an attachment is needed for the walk-behind tractor. Factory-made attachments are not cheap, so craftsmen often make them themselves. Assemble houses snow blower for walk-behind tractor there are four types.

Differences between homemade snow blowers by design

Homemade snow removal mechanisms are considered universal. They can be used as trailed attachments on a mini-tractor, walk-behind tractor or motor-cultivator. In the absence of traction equipment, the snow removal mechanism is equipped with an engine. This homemade product makes a snow clearing machine. Regardless of the traction device used, the design of each type snow blower remains unchanged:

- Blade – used only as an attachment to a walk-behind tractor or mini-tractor. Attach it to a bracket located on the frame of the traction mechanism.

- A screw snow removal mechanism can act as an attachment or an independent machine if the structure is equipped with a motor.This type of snow blower for a walk-behind tractor is considered the most effective.

- A rotary snow blower is also called an air blower or a fan blower. It is also capable of working with its own motor or being used as an attachment.

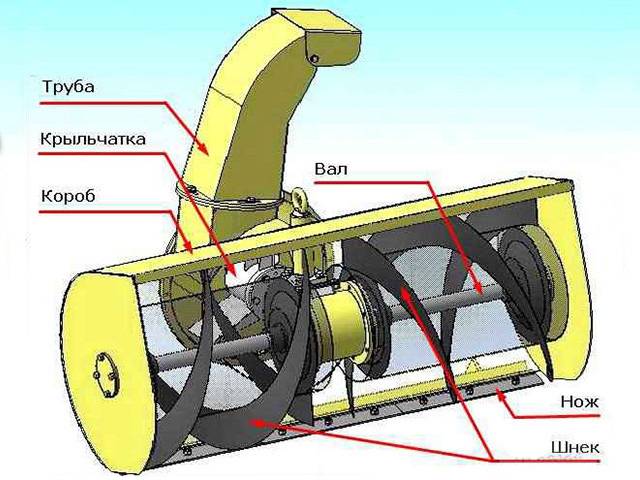

- A rotary auger or combined snow blower has the most complex design. It combines a screw and rotary mechanism inside one housing.

A combined snow blower for a walk-behind tractor is the most productive, but it is very difficult to manufacture. Most often, craftsmen prefer auger attachments.

Converting a walk-behind tractor into a bulldozer

The simplest homemade snow blower For a walk-behind tractor, a blade is considered. Shovel is a hinge. It is attached to a trailer bracket on the frame of the unit, resulting in a small bulldozer. The blade is equipped with a mechanism that allows you to change the angle of rotation of the shovel to move the snow mass to the side.

Make such a snow blower at DIY walk-behind tractor can be from a piece of pipe with a diameter of 270 mm or an old gas cylinder. To do this, the workpiece is marked along lines to make three segments. One of the elements is cut out with a grinder, after which the rods and towing mechanism are welded on the back side.

The principle of operation of the blade is simple. When the walk-behind tractor with the snow blower moves forward, the shovel rake up the snow cover. And since it is installed at an angle, the snow evenly moves towards the side of the road. If the walk-behind tractor needs to return to its original position, the blade is raised and the reverse speed is turned on. To continue harvesting, the shovel is lowered to the ground again and moved forward in first gear.

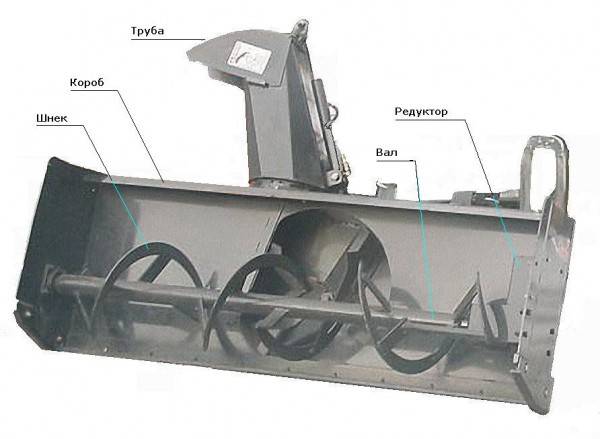

Auger snow blower

A snow blower for an auger-type walk-behind tractor has high productivity. The nozzle consists of a metal semicircular body - a bucket. The auger rotates inside on bearings. Its design resembles a part of a meat grinder. Disc knives are welded onto the shaft in a spiral. They consist of two halves, which converge in turns towards the central part. In this place on the shaft there are rectangular plates - blades. Strictly above them at the top of the body there is a wide hole made - a nozzle, which is connected by a pipe to the outlet sleeve and the guide visor. A stationary knife is attached to the bottom of the bucket for cutting layers of snow.

An auger-type walk-behind snow blower works as follows:

- As the nozzle moves forward, the stationary blade cuts the snow cover and it gets inside the bucket. Here the auger crushes the mass with knives and at the same time moves it towards the center of the body.

- The blades rotate with the auger and pick up the incoming snow. Next, they push it out through the nozzle.

- The operator adjusts the direction of snow emission using a visor.

To connect such snowplows to a walk-behind tractor, a trailing mechanism is used. Torque from the engine to the auger is transmitted by a belt or chain drive.

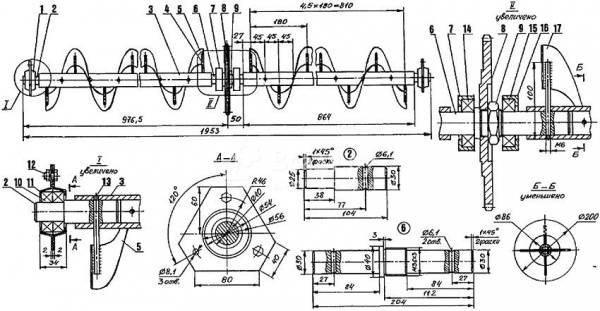

The snow blower body is easy to make. It is bent from any sheet metal. Sidewalls can be cut even from thick plywood. The hubs are bolted in the center.Bearings mounted on the auger shaft will be inserted here. It is more difficult to make the drum itself with knives. In the photo, we suggest looking at the drawings of a snow blower for a walk-behind tractor with your own hands, or, more precisely, a diagram of the auger itself.

The structure consists of a shaft onto which trunnions are welded at the edges. They are mounted on closed type bearings. A chain drive sprocket is attached to one of the axles. You can use a pulley to connect with a belt.

Disc knives are cut from metal. First, they make rings, then saw them and stretch them in different directions to form spiral turns. The knives are attached to the shaft in the direction of the blades.

There are several options for creating knives:

- discs made from a conveyor belt or car tire are suitable for removing loose and freshly fallen snow;

- steel discs with a smooth edge will cope with caked and wet surfaces;

- metal discs with serrated edges are capable of grinding icy layers.

For a screw made with any knives, it is important that there is an equal distance between the turns. Failure to follow this rule will result in the snow blower being thrown around.

Fan snow blower

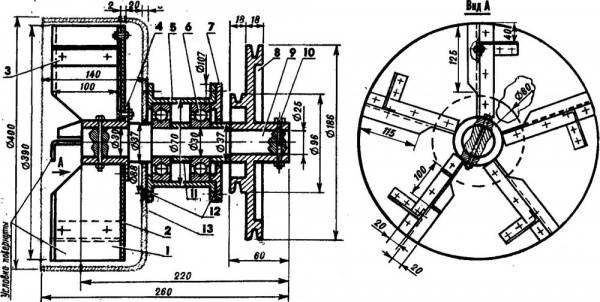

To remove small amounts of loose snow, use a snow blower for a fan-type walk-behind tractor. The main working element of the nozzle is the rotor. The photo shows his drawing.

The diagram shows that the rotor is a structure made of a shaft on which two bearings are mounted. The impeller is an impeller with blades. There are five of them in the drawing, but you can put two, three or four pieces. Torque is transmitted from the walk-behind tractor through pulleys with a V-belt.

The rotor bearing hub is attached to the end of the round snow blower body.It is often made from a metal barrel. To do this, cut off a part of the container 15–20 cm high along with the bottom. The impeller is mounted on the rotor shaft, which extends into the housing. A hole is cut out at the top of the side shelf into which a pipe with a guide visor is welded. To make a fan snow blower from a walk-behind tractor, the attachment is coupled to the frame of the unit and a belt drive is installed.

The operating principle of a fan snow blower is based on snow suction. Guide vanes are welded to the front of the body. Moving forward, the nozzle captures snow with them. The fan blades grind it and mix it with air. The resulting mass is pushed through the nozzle by a strong air flow and flies out to the side at a distance of up to 6 m.

Combined snow blower

Consider in detail how to make a snow blower with your own hands of a screw-rotor type, there is no point. This design consists of two connected nozzles. An auger snow blower for a walk-behind tractor is taken as a basis, after which it is further developed. According to the instructions discussed above, a fan nozzle is made, only the guide blades on the front of the housing are not welded. At this point it is connected to the back of the auger snow blower bucket.

During operation, the auger crushes the snow and delivers it to the fan nozzle housing. Here, a powerful air flow is formed by the impeller blades, which pushes the mass through the outlet sleeve.

The video shows a homemade snow blower:

Reviews

In summing up the results about snow blowers, let's read the reviews of craftsmen who independently created such structures.