Content

A small snow removal unit with a chainsaw engine will help the dacha owner clear the yard and surrounding area of snow. To make homemade products, there is no need to buy expensive spare parts. The frame and body of the snow blower can be welded from metal lying around in the yard, as long as you have a working engine. The more powerful the motor, the more productive homemade snow blower You can make it out of a chainsaw.

How does a snow removal unit work and what does it consist of?

The design and operation of a homemade snow blower is no different from its factory counterparts. The driving force is provided by the motor, so it is desirable that it be powerful. It is better to take an engine for a snow blower from a Druzhba or Ural chainsaw. Motors of these brands are characterized by endurance, power and long service life.

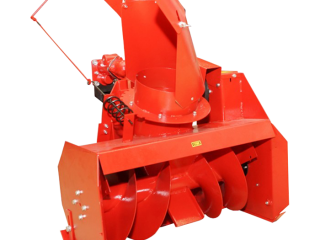

In addition to the chainsaw engine itself, you will need to weld a frame for snow removal equipment. In order for the machine to move itself, it can be equipped with a drive and a set of wheels or tracks can be installed. It's easier to attach runners from below. Then the car will have to be pushed so that it goes like on skis. The snow blower body itself is bent and welded from sheet metal. The working mechanism is a screw.It scoops up snow with disk dosses, grinds it, and two rotating blades push the loose mass through the outlet sleeve.

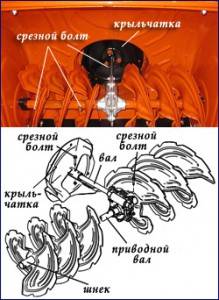

Improved homemade snow blowers are additionally equipped with a rotary attachment. The design resembles a vacuum cleaner and consists of an impeller with welded blades. The snow blower rotor is placed in a round housing, after which it is attached to the back of the auger mechanism bucket. During rotation, the fan sucks in loose snow coming from the auger. Inside the housing, the snow mass is additionally ground and thrown out through a discharge sleeve with a strong air flow.

The order of work when manufacturing a snow blower

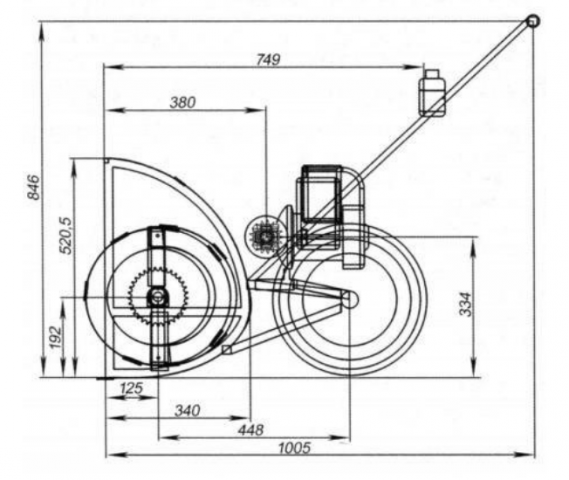

To construct a snow blower from a chainsaw with your own hands, you need to prepare drawings. There is nothing complicated here. The general diagram of the machine can be seen in the photo. The most difficult process will be the process of creating a screw, but this still needs to be achieved. When making a snowplow from a chainsaw, the dimensions of the bucket and auger are calculated so that they capture snow cover 50 cm wide and 40 cm high. If the power of the motor from Druzhba or the Urals allows, the dimensions of the structure can be increased.

So let's get acquainted how to make a snow blower from an old but working chainsaw:

- The first step when making a snow blower from a Ural or Druzhba chainsaw is to check the motor itself for functionality. If the engine starts easily and runs stably, it must be freed from the tire, handle and other mechanisms unnecessary for the snow blower.

- The ladle is welded from a metal sheet.First, a strip 50 cm wide is bent in a semicircle, and then the side shelves are welded. The inside diameter of the bucket should be 2 cm larger than the dimensions of the auger. The optimal dimensions are: the diameter of the rotor disk knives is 28 cm, the diameter of the bucket is 30 cm.

- A hole with a diameter of 150 mm is cut in the top center of the bucket. A pipe for the ejection hose is welded here. If the screw design is improved with a fan, then another hole is cut into the back of the housing. The rotor casing with the impeller will be secured here.

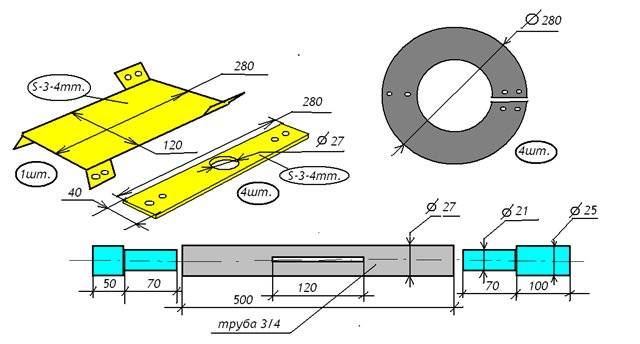

- Shaft do-it-yourself auger for a snow blower can be made from a piece of round metal pipe with a diameter of 20 mm. The blades are welded in the center. They will throw out snow. I weld trunnions to the pipe on both sides. Bearings No. 305 are mounted on them. On the drive side, the trunnion is made longer. An asterisk is placed on it. In a combined auger-rotor design, a gearbox is installed instead of blades, as shown in the photo. It transmits torque from the screw to the fan. To avoid jamming of the bearings on the auger, they should only be installed in the closed type. The plugs will prevent sand and dirt from entering.

- Disc knives are cut from steel sheet. First, the rings are cut out, cut on the side anywhere, and then stretched to the sides. The resulting spiral half-rings are welded onto the shaft in turns towards the blades. It’s easier to leave the edge of the knife even, but such an auger is unlikely to overcome the ice build-up. Here you can try to cut a jagged edge that can easily cope with compacted snow, and also cut through a thin ice crust.

- You can equip homemade snow blowers with an auger with rubber blades. They are often cut out of car tires with a jigsaw. But this design can only cope with loose snow.

- To install the auger inside the bucket, bearing hubs are bolted to the side shelves. It is important to find the center exactly, otherwise the drum will wobble and the knives will cling to the bucket body.

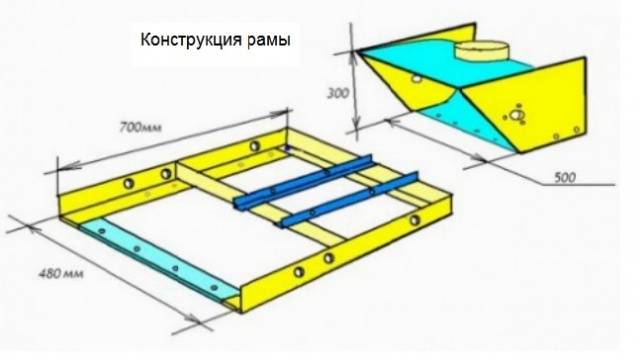

- When the previously made bucket design is equipped with an auger, the time comes to think about attaching a chainsaw engine to the snow blower. Here you will need to weld the frame on which all the elements of the snow blower will be attached.

- The photo shows a diagram of a simple frame. It is welded from a metal corner. The optimal size of the structure is 48x70 cm. A jumper is placed in the middle, and two longitudinal elements are attached to it, fitting them to the fastening elements of the chainsaw motor.

- Any pair of wheels is suitable for driving a snow blower. It can be connected by a drive to a chainsaw motor to create a self-propelled machine. The disadvantage of this design is poor maneuverability in deep snow. It's easier to use wooden runners instead of wheels. The skis move easily on snow and do not fall through.

- When the assembly of the frame with the chassis is completed, a bucket with an auger is attached to it. Behind it they install the engine, removed with their own hands from a chainsaw. The pulleys of the working shaft of the motor and the auger are connected by a belt. If sprockets are selected, then put on the chain.

The entire assembled mechanism of the snow blower must be turned by hand. The auger should rotate easily, and the knives and drive parts should not cling to the frame and bucket elements. After receiving a positive result, the assembly of the snow blower is completed. All that remains is to attach the fuel tank to the frame, make the control handles, and cover all the working mechanisms with a galvanized casing.

The video shows a snow blower powered by a Ural chainsaw motor:

At the end comes the most exciting moment - starting the engine.If no mistakes were made during assembly, the auger will begin to rotate as soon as the motor starts running. The operator just has to put a sleeve with a guide visor on the outlet of the bucket and can try to clear the snow.