Content

A snow blower is more in demand by residents of regions where there is a large amount of precipitation. Factory-made units are expensive, so most craftsmen make them themselves. There is a wide variety of designs for such homemade products. The most common mechanisms are screw type. However, homemade rotary is no less popular. snow blower, in which snow is captured by the fan blades.

Types of rotary snow blowers

The design of a rotary snow blower is quite simple. The unit consists of a round body - a snail. There is a sleeve on top for throwing out snow. Guide vanes are welded to the front of the body. Inside the snail of the snow blower, the rotor rotates at high speeds. It consists of an impeller mounted on a shaft with bearings. The mechanism is driven by an engine. When the snow blower rotor begins to rotate, the impeller blades capture the snow, grind it inside the snail, and then throw it several meters to the side through the sleeve.

A homemade rotary snow thrower can be made of two types:

- With permanently installed motor. In this case, the snow blower works as a full-fledged machine.

- As a hitch for other equipment. They do not install an engine on such rotary homemade products. The snow blower is attached to a walk-behind tractor or to a mini-tractor. The drive is carried out through a belt or chain drive.

Rotary snow blowers differ by engine type:

- Electric rotary models operate almost silently. They are easier to maintain and do not require consumables. The inconvenience is the cable constantly dragging behind the snow blower. You can give preference to a battery model, but the operating time of such a unit is very limited. All electric snow blowers are low-powered. They are usually used in dachas and private courtyards to clear paths from freshly fallen loose snow.

- Gasoline rotary models are much more powerful than electric snow blowers. Their only drawback is more complex engine maintenance, regular refueling and the presence of exhaust gases. However, a gas snow blower is not tied to an outlet. The power of the motor allows the production of large rotor mechanisms. This rotary unit has an increased working width and is able to cope with thick snow cover and even snowdrifts.

By type of movement, rotary snow blowers are:

- Non-self-propelled units move by being pushed by the operator. Typically, electric snow blowers belong to this category, but there are also low-power gasoline models. The technique needs to be pushed slightly. By capturing the cover with the impeller, the snow blower itself will gradually move forward.

- Self-propelled vehicles are most often powered by a gasoline engine. The snow blower itself rides on wheels. The operator only gives him the direction.

It is reasonable to also classify a rotary snow removal attachment as a self-propelled vehicle, although it does not even have a stationary drive. However, there is no need to push it with your hands. The hitch will move with the walk-behind tractor or mini-tractor.

Drawings of rotary snow blowers

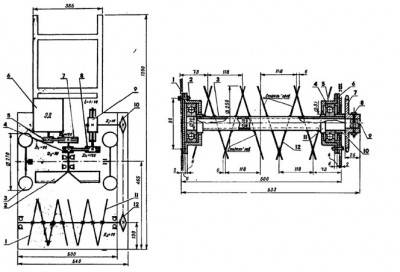

To properly assemble snow removal equipment, you will need drawings. In the photo we suggest you familiarize yourself with the structure of a simple rotary snow blower.

The following scheme is more suitable for mini-tractor owners. The fact is that it is unreasonable to attach a rotary hitch to such powerful equipment. Most often, a combined mechanism is made for a mini-tractor. The hitch consists of an auger and a rotor. This snow blower will cope with large snow drifts.

In a combined snow blower, snow is processed in two stages. The auger captures and grinds the cover, and the rotor mixes the loose mass with air and throws it out through the sleeve under strong pressure.

The operating principle of a rotary snow blower is presented in the video:

Making your own rotary snow blower

The process of making a rotary snow blower with your own hands can be divided into the following steps:

- frame assembly;

- manufacturing of a rotor mechanism;

- welding the casing - volute.

If the snow clearing structure is not attached to other equipment, then the craftsman has one more action to take - installing a motor.

When determining the size of a rotary snow blower, it is optimal to focus on such parameters as to obtain a working width in the range of 48–50 cm. The design of the snow blower will not be bulky, but productive. With this snow blower you can quickly clear the area adjacent to the house, the yard and paths in the garden.

Assembling the frame of a rotary snow blower

The frame serves as the base for the snow blower. All working parts are attached to it. In general terms, the snow blower frame is a rectangular structure welded from corners and a profile. It is not possible to give clear instructions for its manufacture, because everything will depend on the spare parts used. Let's say the motor can be taken from a chainsaw, cultivator, or, in general, an electric motor can be installed. For each unit you will have to come up with an individual mount. If the rotary snow blower is used as a hitch on a walk-behind tractor, then the motor will not be installed. This means that the frame is made shorter so that there is only enough space to attach the rotor with the volute.

If the rotary machine is self-propelled, then a wheel pair attachment point is provided on the frame. A non-self-propelled snowplow is easier to put on skis. To do this, fasteners are welded to the bottom of the frame, and wooden runners are fixed to them.

Snow blower rotor assembly

The most complex component of a snow blower is the rotor. The main requirement is for the impeller. It can have from two to five blades. But that's not the point. Their number depends on personal preference. The main thing is that each blade has the same mass. Otherwise, there will be an imbalance.As the unbalanced impeller rotates, the snow blower will bounce in place due to strong vibration.

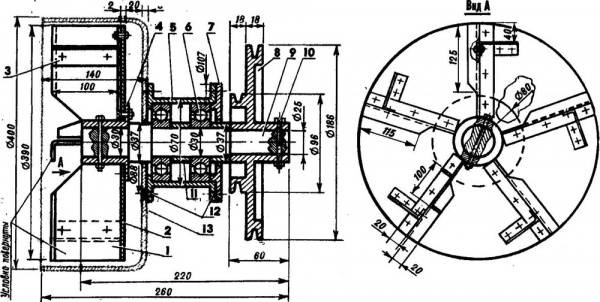

If it is not possible to order the manufacture of a snow blower rotor, you will have to do all the work yourself. The provided drawing can be used as a guide.

The process of making a rotor yourself consists of the following steps:

- First you need to find the shaft. The impeller and bearings will be attached to it. This part will have to be turned only on a lathe. There is no other way out, unless the farm has a shaft of suitable size from other equipment. It is necessary to take into account that in a homemade snow blower rotor there will definitely be at least a small imbalance. The thickness of the shaft is better suited for large bearings. They will be less likely to break due to vibration.

- The rotor impeller is made of metal 2–3 mm thick. First, draw a circle of the required diameter on the sheet. Usually the size is 29–32 cm. The workpiece is cut out with a grinder or jigsaw. It is not advisable to use welding, as the heat will cause the metal to warp. The cut disk is processed on a sharpener and a file so that a perfectly even circle is obtained.

- A hole is drilled strictly in the center on the disk according to the diameter of the shaft. The axle can simply be welded to the workpiece, but then the rotor will turn out to be non-separable. This will make it difficult to repair in the future. It makes sense to cut a thread on the axle and tighten the disc with nuts.

- Now it's time to make the blades themselves. They are cut from similar metal. The pieces should be perfectly identical. It is advisable to weigh each blade.The smaller the difference in grams, the weaker the vibration of the snow blower due to imbalance will be felt. The finished blades are attached from the center of the disk to its edge at the same distance from each other.

At this point, the blanks for the snow blower rotor are ready. Now it remains to install two bearings on the shaft. They require a hub. It can be made from a piece of pipe of the appropriate diameter. Four lugs are welded onto the hub. You can simply attach a ready-made flange with holes. At this point the hub will be fixed to the rear wall of the cochlea.

Making a snail

The shape of the rotary snow blower housing is a bit like a snail, which is why it is called that. To make it, you will need a piece of pipe of a suitable diameter, 15–20 cm long. One side of the ring is tightly welded with a sheet of metal. This will be the back wall of the volute, to which the rotor bearing hub is attached. At the front, two guide vanes are welded to the sides of the ring.

A hole is cut in the upper part of the ring and a pipe for the sleeve is welded. The front part of the snail needs to be closed by 1/3 so that the snow does not fly in front of the rotor, but is diverted through the sleeve. It is better to make the plug removable with stiletto heels. This design will allow convenient access to the impeller.

Now all that remains is to secure the rotor inside the casing. To do this, a hole for the shaft is drilled in the center of the rear wall of the cochlea. The rotor is put in place, pressing the bearing hub tightly to the casing. The location of the mounting holes is marked along the flange lugs. The rotor is removed from the casing, drilling is performed, after which the mechanism is put in place and the hub is bolted to the rear wall of the volute.

So, inside the round housing we have a protruding rotor shaft. The impeller is placed on it and carefully tightened with nuts.On the outside of the volute there remains a hub with bearings and a second protruding end of the shaft. A belt drive pulley is mounted on it. If preference is given to a chain drive, a sprocket from a moped is attached instead of a pulley.

The finished rotor mechanism is installed on the frame, after which further configuration of the snow blower begins, depending on the selected model. That is, they install a motor or connect a hitch to a walk-behind tractor and set up the drive.

Conclusion

The advantage of a homemade rotary is the ability to manufacture a snow blower with the required working width, as well as significant savings in money.