Content

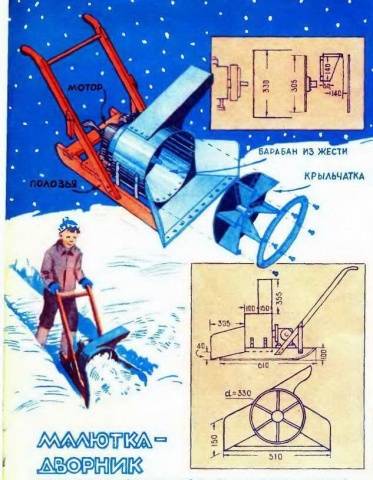

Technique for snow removal In the store it is expensive and not everyone can afford it. A way out of the situation can be found if you collect homemade snow blower from a trimmer that will help clear the yard of freshly fallen snow.

Converting a trimmer to a snow blower

The design of such a homemade product is so simple that you don’t have to make complex drawings and grind out parts. You just need to make an impeller, which is attached to the trimmer instead of a knife, and place this entire structure in the casing.

Snow Blower Assembly Guide

Not every trimmer is suitable for making a snow blower. If the farm has an electric or brush cutter with a curved bar, in which the torque is transmitted to the blade by a flexible cable, then the conversion process does not even need to begin. The fact is that such models of trimmers are low-power. The performance of the snow blower will be weak, and the engine will constantly overheat.

A good snow blower will come from a powerful trimmer with a level shaft. Such an electric or gasoline scythe is characterized by the transmission of torque to the knife through a rigid shaft and gearbox.

The construction of snow removal equipment is simple. The working element is a nozzle, which is placed instead of a knife. It is an impeller with blades.To make this part you will need steel 1.5 mm thick. The impeller must be placed in a casing - a volute. For its manufacture, a piece of large diameter pipe is taken, usually within 300 mm.

Converting a trimmer into a snow blower with your own hands will do without complex drawings, but you need to have at least a simple diagram on hand. It will help create a general idea of the design.

Now let's take a step-by-step look at how to make a snow blower with your own hands from an electric or lawn mower:

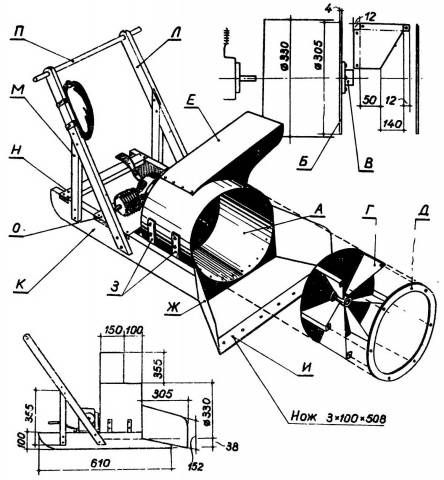

- Making a snow blower begins with the body. If you are lucky enough to get a beer barrel, then you need to cut a piece 150 mm long from it. The workpiece is needed together with the bottom, since the trimmer gearbox will be attached to it.

- A hole is drilled in the center of the bottom. Its diameter should be enough to accommodate the trimmer's working shaft, onto which the impeller-shaped attachment will be placed. Around the large hole you need to mark the mounting locations for the gearbox. Usually these are three dots. Holes for bolts are drilled according to the markings.

- Now you need to make an exit for the snow blower - a deflector through which the snow will be thrown out. A hole is cut in the side shelf of the case. It can be made square or round at your discretion. Hole diameter – 100 mm. The pipe is welded to it later. Now you need to cut a half-circle shape from a sheet of steel. This plug is used to weld 1/3 of the end of the front part of the snail body. The plug will prevent snow from flying forward from the snail, but will direct it into the deflector.The deflector hole should be located in the center of the front plug.

- Next, you need to make a rotor for the snow blower, that is, the impeller itself, which will throw out snow. The trimmer's disc blade is used as a basis. But first, four blades measuring 250x100 mm are cut out of steel. The blanks are made perfectly the same size to avoid imbalance. The finished blades are welded crosswise to the disk.

- Now it's time to finish the deflector. The hole on the body is already ready, now you need to attach the pipe to it. It can be bent from galvanized steel. The pipe is made 100 mm high and welded to the body. An elbow of similar length is attached to it so that the snow is thrown to the side. It is better to make the deflector round. You don’t have to make an elbow for such a pipe yourself. It can be taken from a plastic sewer with a diameter of 100 mm.

- The last part left to make is the guide vane. It is cut from a sheet of steel. The result should be a workpiece measuring 300x400 mm. Sides with a height of 20 mm are folded on the sides. The finished blade is welded to the bottom of the body from the front side.

- All the parts of the snow blower are ready, all that remains is to assemble them into a single structure. First, the trimmer gearbox is bolted to the volute. A shaft comes out inside the housing. They put a homemade nozzle with blades on it.

A do-it-yourself snow removal unit from a trimmer will be considered ready when the rotor structure is installed on the frame. It is enough to weld a regular rectangle from the corners. Wooden runners are attached to the frame from below. Skis make it easier to push a snow blower through the snow. The control handle is the trimmer's original rod.

The video shows an example of a snow removal unit from a trimmer:

What is better to attach to the trimmer: an auger or a rotor?

When making a snow blower from a trimmer, there are two options for installing the working mechanism: an auger and a rotor. Let's look at the differences between the designs, as well as their positive and negative sides.

Screw mechanism

In terms of efficiency, the auger outperforms the rotor. The mechanism consists of screw disk knives. Rotating, they cut even stale, wet and icy cover. The spiral turns move the collected mass to the center of the body, where the blades push it through the deflector. If you connect such an attachment to the trimmer, it will be able to throw snow to the side at a distance of up to 3 m. However, you need to take into account that the auger mechanism creates a large load on the engine. This is especially true when clearing hard snow. For this attachment, you can only use a powerful trimmer.

It is difficult to make a nozzle yourself due to the design of the auger. You will need to accurately measure the distance between each turn. If it is different, the snow blower will throw to the sides while working. A lot of turning work will still be required. The auger rotates on bearings, so you need to grind out the axles and hubs. As an option, auger shovel You can buy it in a store, and at home you just need to adapt it to the trimmer.

Rotary mechanism

The advantage of the rotary mechanism is its ease of assembly. After all, the mechanical part remains practically original. The impeller is made of a disc blade that fits onto the trimmer head. The snow throw range of this design can reach 6 m.

The disadvantage of the rotor is its use only on loose and freshly fallen cover.Wet snow will stick to the snail, and pieces of ice may get stuck between the blades.

You can choose any mechanical part of the snow blower as you wish. But in any case, you need to remember that the trimmer is not designed for such a large load. The engine needs to take a break during operation so that it does not overheat.