Content

- 1 Is it necessary to make a clay castle around the well?

- 2 Advantages and disadvantages of a clay castle around a well

- 3 How to choose clay for a groundwater well lock

- 4 How to make a clay castle for a well with your own hands

- 5 How to make a blind area for a clay castle for a well

- 6 Repair and restoration of a clay castle for a well

- 7 Conclusion

It is not difficult to build a clay castle for a well with your own hands. This is necessary to ensure that contaminated water does not get into clean water. The seal on the seams between the rings will last longer with the added protection of compacted clay.

Is it necessary to make a clay castle around the well?

Doubts about the need for a clay castle arise when the consumer sees the consequences of improperly manufacturing this structure. If a carelessly laid element collapses, it will damage the well trunk, and eroded earth will fall inside. This can be avoided. Do not forget about frost heaving, especially if the groundwater level is high. Sometimes drainage is necessary. The well and blind area should be insulated to prevent the top rings from being torn off by soil heaving.

A clay castle is necessary so that the high water can take a long detour through the sand.Otherwise, the contaminated water will immediately rise to the top of the well and if the slightest crack occurs, it will get into the drinking water. Before arranging a clay castle, you need to wait for the earth to shrink. Hired craftsmen offer to do it right away, and this threatens the formation of cavities between the clay layer and the settled soil. It is advisable to wait time; you can complete this work yourself.

Advantages and disadvantages of a clay castle around a well

There are debates about the advisability of building a clay castle, especially with your own hands. There are still some disadvantages:

- you will need to find clay with a sand content of no more than 30%, and at the site of excavation for a well there may not be such;

- Complete waterproofing with a clay “seal” alone is difficult to achieve; coating of seams on the rings will still be required;

- the clay will have to be soaked and kneaded by hand; mechanical stirring is not suitable;

- It takes time for the soil and the clay layer to settle; if it is laid in a hurry, the lock will not work.

Contract teams may offer to do everything in one season, but their motivation is to get paid as quickly as possible. When building a well with your own hands, many have the opportunity to wait. The advantages of a clay castle are significant for some:

- clay is an inexpensive material, sometimes even free;

- if installed correctly, repairs will not be required for years;

- elimination of defects or consequences of wear and tear is inexpensive;

- the well will be reliably protected from melt and rainwater.

How to choose clay for a groundwater well lock

To make a castle you will need fatty clay, the permissible admixture of sand in it is up to 15%. To check, roll a small ball of moistened raw material with your hands and drop it from a height of 1 m onto a hard surface.If the ball has broken into pieces or is badly damaged, the sand admixture is unacceptably high. If there are only small cracks on the sides, it’s suitable.

You can also press on the ball with your hand and see if there are large cracks around the edges. In addition, to check, a rolled lump of clay or a cake made from it must be dried with good ventilation or even in the sun. The more sand in the composition, the less the sample will crack.

Oily clay will crack when dried, but holds its shape better when wet.

The clay is soaked to increase plasticity. If possible, they are harvested in the fall and left in the open for the winter.

If there is no time, soaking is carried out for 1-3 days. The soaked clay must be kneaded - without this procedure it will not become waterproofing. The process is quite labor-intensive, it’s hard to do it with your hands, but a concrete mixer or a mixer on a hammer drill simply mixes, and does not crush. Traditional method: knead (knead) with your feet. To increase plasticity and improve water-repellent properties, you can add 10-15% slaked lime, but contact with the skin should be avoided. The finished clay has the consistency of plasticine; it is placed wet.

How to make a clay castle for a well with your own hands

It is advisable to start laying a clay castle after the soil has settled, which continues for at least 1 year after the construction of the well itself. Concrete rings located in the ground should not be wrapped in thermal insulation material, especially foam. The Stenophone mentioned below will crumble and begin to decompose in the ground.

It is recommended to treat the outer part of the trunk with built-up waterproofing or bitumen, but the material should not be roofing, but designed to work in the ground. This will give a better chance of maintaining the integrity of the ring connections during seasonal soil movements, if they do occur.

Frost protection should be placed on top. The well itself will maintain a positive temperature in winter, but the clay around it must not be allowed to freeze; highly heaving material will damage the upper rings when expanding. When installing an insulated “house” on a concrete well and a warm blind area, the clay castle will not freeze, will not expand, and the trunk will remain intact.

In this photo, EPS is used to insulate the well trunk; the probability of freezing of the clay castle increases, which will lead to the tearing off of the upper ring:

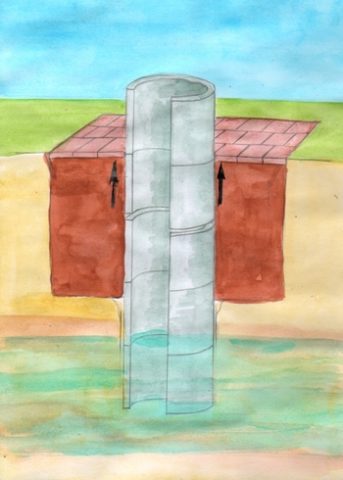

The width of the clay castle is 1 m from the well, the depth is at least 2 m, but always deeper than the freezing level of the soil. Clay must be poured above ground level to ensure a slope away from the well. For greater density of the castle, laying should be done in layers of 10-15 cm, carefully compacting each of them using a tool. It can be a heavy log with handles. You should not try to hammer the clay into the lock by stomping your feet - this is ineffective.

How to make a blind area for a clay castle for a well

The blind area protects the clay castle from erosion and freezing. The cause of frost heaving is sub-zero temperature and water. It is enough to remove one of these factors so that the well does not become deformed after winter.The concrete shaft itself is buried much below the freezing level, this is enough to heat the surrounding soil.

Drainage is necessary when the groundwater level is high in spring and autumn; the main difficulty is that it is not clear where to discharge the drainage. A natural circulation system will require a slope. If the well is located in a low area, the task becomes more complicated. As a last resort, you can install a drainage pump, but it will work constantly, as, for example, when pumping water from basements that are heated in spring in wetlands. The drainage system will also require a manhole with a lock on the lid.

The width of the blind area is at least 1.5 m, and in addition to insulation, it must also contain waterproofing. Clay can also be used here, in a layer of 0.3-0.5 m, also compacted, but in this case it is better to postpone the work for a year. The lower part of the structure may settle, and melt and rain water will flow into the resulting gap.

The blind area is covered with wood or tiles on top, that is, a material that will not be damaged by ground movement. In case of repair, it is better to leave the finishing layer dismountable.

Repair and restoration of a clay castle for a well

The reasons for repairs can be different: the clay castle could be washed away by rain or high water, water entered the shaft through the gaps and the clay seeped inside, an unpleasant rotten smell suggests that a cavity has formed somewhere.

The clay castle can settle over time and peel off from the blind area.To eliminate the resulting voids, the flooring, waterproofing and insulation are removed, and the lock itself and the inner walls of the well are inspected. If no leaks of clayey water are detected into the well, and no cracks are visible from the outside, the top layer can simply be topped up.

Traces of dirty water leaking into the well, cracks on the outside, a suspiciously high level of filling (out of season), a rotten smell (after rain, for example) are signs that the castle needs to be redone.

The dug up old clay needs to be soaked and kneaded again, and the walls of the well shaft should be inspected for cracks. Leaks from the inside will also be a clue to where the seams have come apart; a water seal may be required in these places. Concrete locks in well rings can be destroyed. External insulation, if any, should be removed and replaced with new one. There is no point in looking for breaks; water can create a “pocket” and the material will peel off in places.

Conclusion

When making a clay castle for a well with your own hands, you should take into account the subtleties of this technique. The task is to obtain water from the depths without impurities, and negligence in execution will lead to the opposite result. The method itself is quite good and economical, but it will require a responsible approach.