Content

- 1 Features of making houses for wells

- 2 Types of well houses

- 3 How to cover a well house

- 4 Which house for a well is better?

- 5 DIY well house dimensions

- 6 DIY drawings of houses for a well

- 7 How to build a well house with your own hands

- 8 How to install a house on a well

- 9 How to make a canopy over a well with your own hands

- 10 Photos of houses above the well

- 11 Conclusion

A well on a site without appropriate design looks quite prosaic - a gate with a bucket on posts. Anyone can transform such an unsightly structure into a beautiful part of the landscape. To make a well house with your own hands, you need to have a minimum of construction skills, imagination and suitable materials.

Features of making houses for wells

The features of making a house for a well with your own hands directly depend on its functionality. The structure above the water shaft has the following options:

- Debris protection.The house prevents precipitation, dust, leaves, insects, small rodents, and preparations from entering the source when spraying and treating plants on the site.

- It prevents water from freezing in winter, this is especially true for northern regions with a harsh climate.

- Serves as a barrier against the aggressive effects of sunlight.

- Prevents children and pets from entering the well shaft.

- Decorates the site, being an addition to the landscape.

With a minimum of effort and materials, beautiful houses for a well become not only a practical solution, but also delight the eyes of the owners and guests of a country house.

Types of well houses

The design of the top of the well can vary depending on the type and type of structure. You can cover the shaft with your own hands with a simple panel box or make a real house with many elements. The roof of the structure is made in the form of an umbrella, single or gable, with a sharp or gentle slope.

Doors for access to water can be:

- single-leaf;

- bivalve;

- sliding.

Depending on the type of well house, there are open and closed options. An open house is the construction of a roof on the supports of a lifting mechanism.

An enclosed structure is a structure with walls, a roof, and a door for access to water.

Closed options are relevant if a pump is used to collect water. To protect equipment, many summer residents build closed well houses with their own hands with a door that is locked.

How to cover a well house

To design a well, materials are usually used that are in harmony with the rest of the outbuildings on the site.

To do this, buy the necessary components in stores, or you can use those fragments of material that are left after building a house, bathhouse, or garage with your own hands. To design a ring over a shaft, sometimes it is simply enough to apply cement mortar to it and, after drawing a relief outline, decorate it with small stones or fragments of tiles. For a more thorough construction, suitable building materials are used.

House for a well made of timber

Wood blocks are the most popular materials in the manufacture of structures for water supply shafts. They make a frame, racks and a canopy over the well from wood with their own hands.

Wood is chosen not only for its ease of working with it, but also for its durability, environmental friendliness, availability of material and beauty of design.

Metal well house

Well houses made of metal are characterized by maximum resistance to environmental influences and damage. Metal, as a durable and reliable material, is used to form the frame or the entire structure.

Iron buildings can be the simplest structures in the form of a galvanized box over a shaft.

When you decorate with your own hands with forged elements of iron structures, they become designer compositions.

When choosing iron to protect a mine on a site, builders recommend using special preparations to avoid rust.

Plastic well house

Plastic is short-lived, but lightweight, so it is often used for finishing moving structural elements.For example, a molded plastic cover that covers the shaft performs a lightweight function of the structure.

When you need to make a light roof for a well with your own hands, plastic is a good material for covering an opening structure:

House on a well made of siding

Siding is convenient for finishing a well due to the ease of assembly of the elements and the variety of colors. A large number of initial colors helps you make a well house with your own hands in any tone, for example, as the main building on the site.

Siding allows you to make small well houses neat and functional.

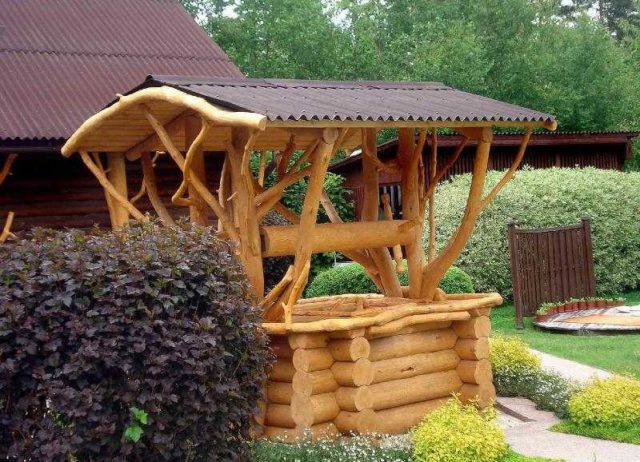

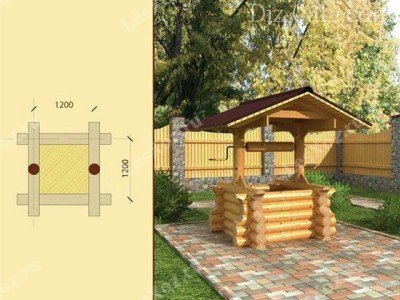

House for a well made of rounded logs

When constructing structures, solid beams are popular. A do-it-yourself well house made from rounded logs is solid and massive. Typically, such structures are built in a quadrangular shape; the corners are connected with or without a remainder.

In this version, the log house breathes of antiquity and the life of our ancestors, especially if the house is complemented by an openwork cornice.

Houses for wells made of corrugated pipes and corrugated sheets

Profile pipes allow you to make the frame of a well house with your own hands, durable and of high quality. Corrugated sheets, as an economical and corrosion-resistant material, are a popular choice of base when forming the roof of a structure.

The owners of the site use corrugated sheets and profile pipes as the main material for the construction of a water supply house most often due to the fact that, as a rule, as many scraps as are left from the roof or fence are enough for the well.

Which house for a well is better?

In order to choose the best option for a well house, you need to consider several factors:

- Reliability and durability of the design.As a rule, a well on a site is built for more than one year. For the same reason, the house for the well must be durable, especially since it is located in the open air and is constantly exposed to natural factors.

- Event budget. Some materials and possible additional services of a narrow profile (forging, welding, wood carving) are quite expensive. There are design options that can be made from existing construction remains with your own hands - this can be a decisive factor when choosing a house for a well.

- The combination of a well structure with the main buildings on the site. Landscape designers recommend that when choosing a house siding, you should focus on other elements of the yard and keep the entire design in the same style.

- Ease of use. Drinking water is a constant need, so the house for the well should be comfortable. It is necessary to provide a place for a bucket, a canopy from possible rain.

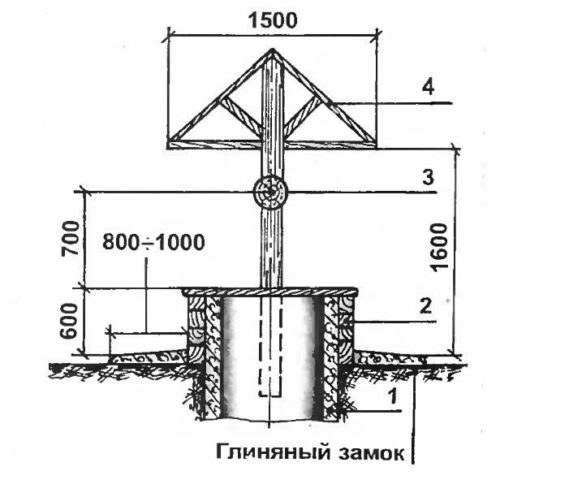

DIY well house dimensions

The size of each specific house depends on the width of the shaft and the head. If the well is made of concrete rings, then their size can vary from 70 cm to 1.5 m. The frame parameters should be based on the outer diameter of the head. It is believed that the optimal height of the house above the well is about 120 cm. It is better to choose a roof slope angle of at least 60°. With this indicator, the roof will withstand wind loads and will not accumulate snow. The best option for calculating the parameters when making a house for a well with your own hands is a simple drawing with dimensions based on the existing head.

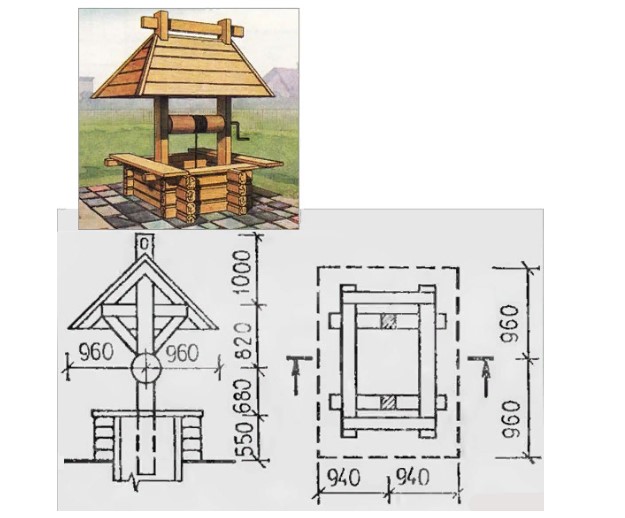

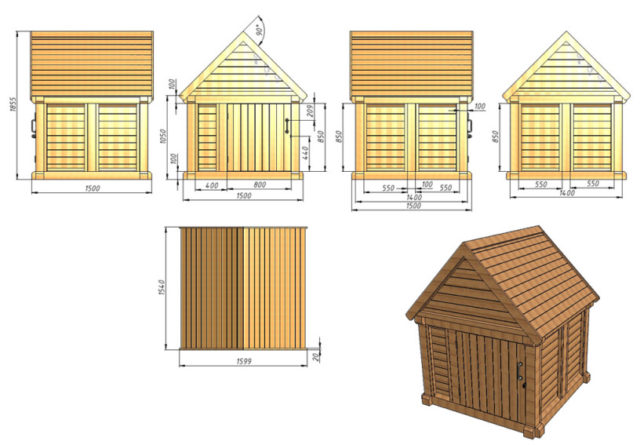

DIY drawings of houses for a well

After the initial dimensions of the well are recorded, a design drawing is drawn up taking into account the material.

A schematic transfer of the model onto paper and drawing of the parameters can be done in any format - the main thing is that it is clear and convenient for the performer to work with such a plan.

If the dimensions of the head are suitable, then you can use ready-made drawings of a well house with your own hands, choosing the appropriate option in the photo.

How to build a well house with your own hands

In order to build a well house with your own hands, you can use proven master classes with step-by-step instructions.

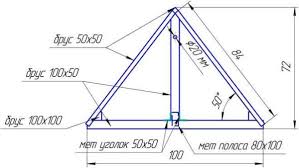

Gable house made of wood

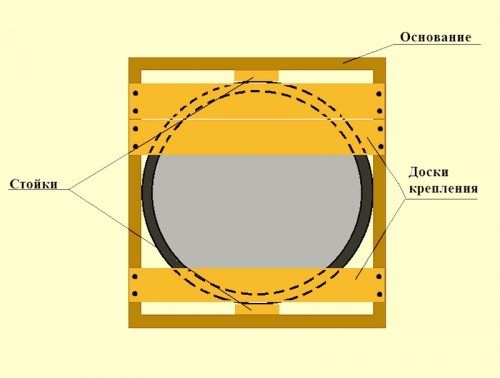

This option is suitable for a novice craftsman and does not take much time to make. First, measure the diameter of the shaft head. Based on this data, the base of the structure will be made.

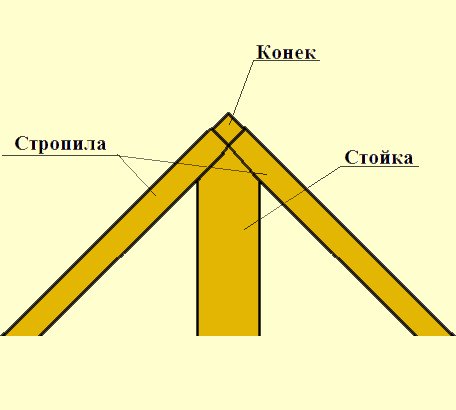

The wooden frame is made from 50*100 mm timber, fixed with corners. The correctness and evenness of the structure will allow you to check the building level; for this you need to find a level place. From beams of the same section (50*100), racks 70 cm long are placed perpendicular to the base, fastening the structure with iron corners. At the top they are connected by a ridge - a 50*50 mm beam.

After this, rafters are attached to the posts and corners of the base. In order for all parts of the structure to fit against each other, the top of the racks is cut at an angle of 45°.

A wide (at least 30 cm) board is attached to one side of the frame, on which a bucket can later be placed. Narrow boards are stuffed onto the other sides for structural strength and as a frame that will hold the house on the head.The finished base is placed on the well ring and secured with bolts.

You can start making the gate. In order for the water intake to be comfortable for the user, it is necessary to take into account the features of the wrench:

- The wider the drum, the fewer rotations you need to make to get the container out of the shaft.

- The length of the handle affects the effort required to lift - the larger the radius of rotation, the easier it is to draw water.

To form a gate with your own hands, take a log with a diameter of at least 20 cm and a length that is 10 cm shorter than the distance between the posts.

Cut rings 5 cm long from a metal pipe with a cross-section of 35 mm and drive them into the ends of the log to protect it from splitting. Drill holes in the rings up to 10 cm each. Two blanks are made from a metal rod with a cross-section of 35 mm: a short one of 20 cm and a long one for the handle of 100 cm. In order for the rod to fit more easily into the wooden blank and not rotate during operation of the mechanism, one of its ends is flattened.

All parts of the knob are assembled into a single element, and for strength they are welded to metal disks.

Now you can install and secure the gate tightly in the vertical posts.

The door can be made from 2-3 boards of the selected size, connecting them on the reverse side with two transverse bars and one diagonal. The door is attached to the frame with hinges using screws or nails.

The base of the house is sheathed with boards or clapboards as desired.

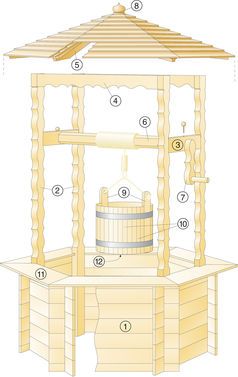

Log house

The log house is made from rounded logs in a classic rustic style. To make a well house with your own hands, you should use a simple drawing that shows the dimensions of the material and the mounting locations for the posts.

Logs of the same length are cut according to the size of the head and laid out around the shaft. The protruding edges can have figured cutouts as decoration for the structure. Vertical posts are attached to the massive structure, which are provided with supports for strength. A gate with a chain and a bucket is attached to the supports, and a roof frame is erected. Due to the solidity of the structure, the roof can be sheathed with any material - slate, roofing felt, tiles.

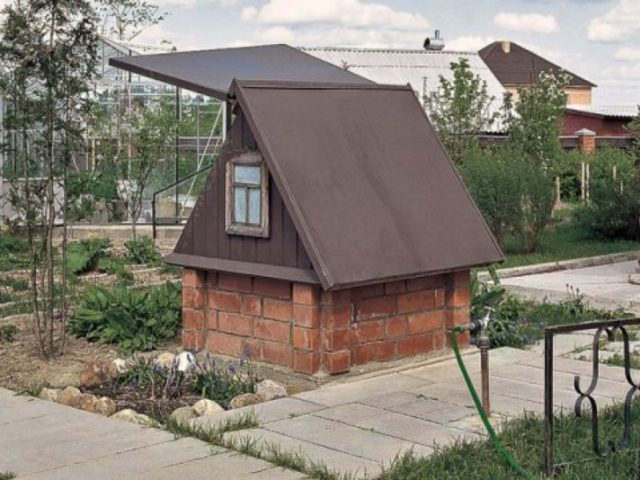

Solid house from the ground

There is an option to make a closed structure from a metal profile with your own hands, when the concrete ring is hidden in the house. The dimensions of the frame must be such that the structure can be freely placed on the head. The height is selected individually - so that you can bend over and get the bucket.

The profile must be made of thick galvanized metal. Two identical frames are assembled from the guides - one will go on the floor, and the second will be above the head.

To make a triangle, the sidewalls of two profiles are cut and, having attached a vertical post in the middle of the frame, the cut corner is fixed to it. The same is done on the other side of the base. Two triangles are connected by a crossbar.

On the side of the base where the door is supposed to be, additional racks are installed.

A roof is attached to the finished frame - corrugated sheets or, having previously secured the base with plywood, soft tiles.The sides are sheathed with existing material - siding or clapboard.

How to install a house on a well

A well house, made by hand or purchased from a manufacturer, is installed on the head without much effort, if the dimensions of the shaft and the outer ring are taken into account. The shape of the house does not matter - whether it is a square frame or a round base, it is simply placed on the concrete base of the well.

A mandatory step in installing a house on a well is the final fastening of the frame, roof and other elements. This is done using a screwdriver or welding if the structure is forged.

How to make a canopy over a well with your own hands

Sometimes it is better to do without building a house - to protect the water and decorate the well with a canopy.

The choice of material for the canopy is varied:

- tree;

- forging;

- plastic;

- profiled sheet

Often this method is used to complete a beautiful stone cap, making a decorative canopy from a suitable material with your own hands. When choosing this option, the following conditions must be met:

- Access to water must be sealed with a lid to prevent debris from entering the shaft.

- The canopy must protect from precipitation, especially from slanting rain.

- The structure must be made in the same style as the house and other buildings.

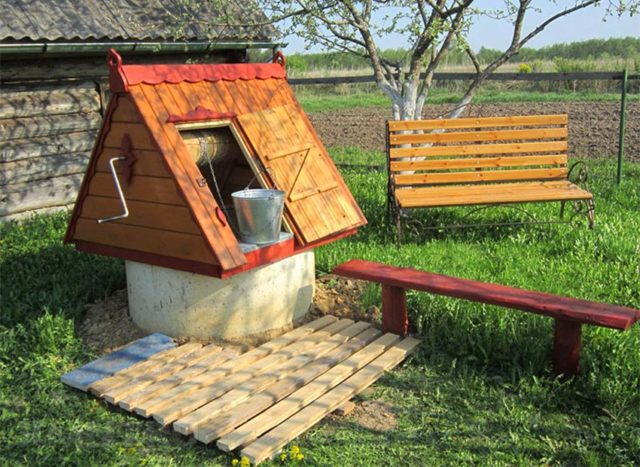

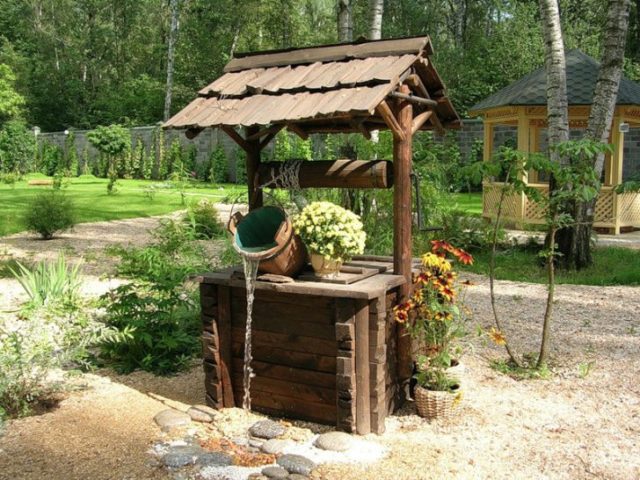

Photos of houses above the well

In order to decorate a well with your own hands, you should use photos of ready-made models or, inspired by an idea, create an individual, unique design.

Houses made in oriental style are an unexpected and bold design option.

With the addition of elementary LEDs, such structures look breathtaking at night.

Simple structures, made by hand according to classical standards, do not take much time to install and look neat.

Conclusion

A do-it-yourself well house is a competent completion of the arrangement of a water supply on the site. Thanks to the simplicity of execution and variations of functional models, this design will effectively retain water and become an individual design decoration of any landscape.