Content

Traditionally, in private courtyards, we are used to building a rectangular basement. A round cellar is less common, and it seems unusual or too cramped to us. In fact, there is nothing outlandish in this storage. The walls of round basements are much stronger than their rectangular counterparts, they are erected faster, and less material is consumed. Now manufacturers have begun to produce round caissons made of plastic, equipped for a full-fledged cellar.

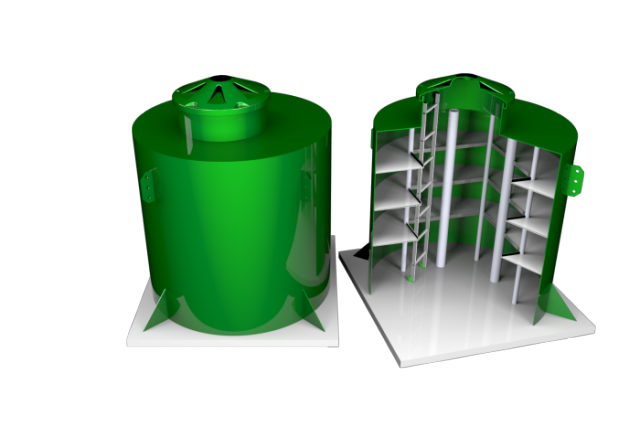

Plastic round cellar

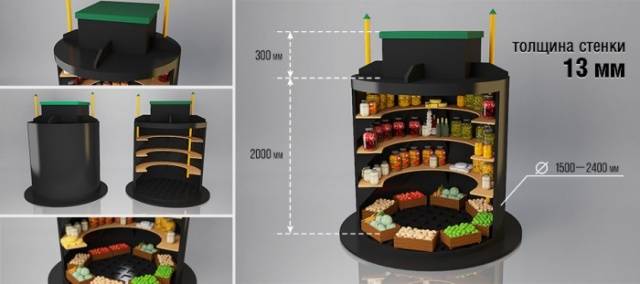

A plastic round cellar is an ordinary vertical cellar for storing vegetables and canning. You cannot do it yourself. Only factory-made caissons are used. A person buys not just a round barrel, but a ready-made cellar with all the equipment. The caisson is equipped with shelves, an aluminum ladder, a ventilation system, electrical wiring and lighting. Typically the chamber height is 1.8 m. The sealed hatch is located on top, but there are caisson models with a side entrance.

According to the production method, round plastic cellars are divided into two types:

- Suture cellars are made from sheets of plastic. Individual fragments of the caisson are connected by welding.

- Seamless cellars are produced using the rotational molding method. Such caissons are considered the most reliable, since the possibility of depressurization at the seams is eliminated. To make a round cellar, a special mold is used, into which polymer is poured. Special mechanisms begin to rotate the mold, which then heats it up. The molten polymer spreads evenly, forming a perfectly round caisson shape.

Well-known manufacturers of plastic cellars include Triton and Tingard. As an example, let's take a brief look at the caisson from the manufacturer Triton.

The plastic cellar of this brand is characterized by 100% tightness and a long service life. Seamless technology made it possible to obtain a durable structure that will not burst at the joint due to soil pressure. The walls of the caisson are made of food-grade plastic with a thickness of 13–15 mm. Stiffening ribs help resist soil pressure.

The video shows a plastic cellar:

Positive features of a plastic cellar

In many cases, using a plastic caisson is more profitable than building a stone storage facility. Let's look at the positive aspects of such a storage:

- The cellars are made of food-grade plastic, harmless to humans. Cheap caissons from unknown manufacturers are made from poor raw materials. Low-quality plastic constantly emits unpleasant toxic odors, which are easily absorbed by stored vegetables. It is better to avoid such products.

- The robust body is up to 15 mm thick, and additional stiffening ribs help withstand earth loads. A round plastic caisson is as strong as a brick storage facility.

- All wooden shelves and other parts are treated with a special impregnation that protects the wood from the harmful effects of dampness and destruction by insects.

- The round plastic caisson is easy to install. It can be used even in areas with high groundwater levels.

- The storage facility is equipped with effective ventilation. It prevents condensation and draws out all the unpleasant odors if the vegetables suddenly go bad.

- Thanks to ventilation and food-grade plastic that does not emit bad odors, the caisson can be used for storing food.

The disadvantages of plastic storage include its high cost and fixed standard size.

Requirements for installation of a round plastic cellar

Before you start installing a round plastic cellar, you need to consider several important points:

- When marking the dimensions of the pit on your site, you need to take into account that they must be larger than the dimensions of the caisson. Typically, the depth of the pit is approximately 2.3 m, and a gap of at least 25 cm is left between the walls of the pit and the cellar.

- Despite the fact that the caisson is plastic, it has an impressive weight. To lower a round cellar into a pit you will need lifting equipment.

- The top of the caisson is covered with soil. In order to maintain a constant microclimate inside the storage facility, it must be insulated before backfilling.

Having mastered these few rules, you can begin installing a round storage unit.

Installation process of a plastic caisson

Despite the fact that the storage unit resembles a large plastic barrel that you can install yourself, it is better to entrust its installation to specialists. They know all the weak points of this design. The caisson installation process looks something like this:

- a pit is dug in the selected area;

- the bottom of the pit is filled with concrete or a reinforced concrete slab is laid;

- the caisson is lowered into the pit using a crane;

- the cellar is fixed to the concrete bottom with slings and anchors;

- perform backfilling with sand-cement dry mixture.

Once again, we must remind you that we have considered the main installation details. In addition, there are many more nuances related to setting up ventilation, power supply, etc. All these issues should be dealt with by specialists.

And finally, two important questions:

- Is it necessary to insulate plastic storage? This is a personal matter, and there are a lot of opinions on this matter. The caisson may not be insulated, but then temperature changes will be observed inside. Natural ventilation may not be able to cope with air exchange, and condensation may appear inside the storage facility. In general, plastic walls perfectly transmit the cold coming from the ground. If vegetables are stored in the caisson, then it definitely needs to be insulated.

- Is it possible to change the ventilation yourself? Then we need to ask a second question. What for? The manufacturer has provided a natural ventilation system consisting of a set of air ducts. An unreasonable change in the design will lead to depressurization of the caisson. In some cases, it happens that when storing a large amount of vegetables, condensation forms inside the storage facility. The natural ventilation system does not do its job. In this case, specialists are hired to install forced ventilation.

You cannot make any changes to plastic caissons yourself. If problems arise, it is better to consult with specialists.

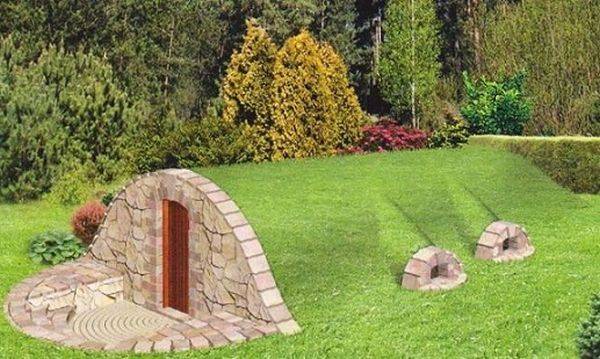

Stone round cellar

You can build a circular cellar with your own hands only from stone. Moreover, the hole can be made from above according to the principle of a plastic caisson. Although for homemade cellars a side entrance is more acceptable, as shown in the photo.

So why do owners sometimes prefer the round shape of a stone cellar? To answer this question, let's look at the positive aspects of this basement:

- round brick walls can withstand greater earth pressure;

- construction of a round basement requires 12% less building material than a rectangular cellar;

- the absence of corners allows the storage to evenly maintain the required temperature and humidity;

- laying out a circle of brick is easier than pushing out the corners of a rectangular basement.

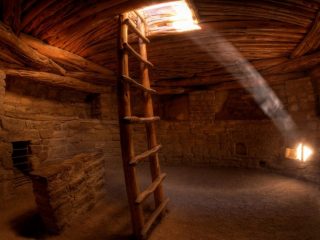

Before you figure out how to make a round stone cellar, you need to decide what the requirements are for it. Firstly, the area and volume of the storage must accommodate all supplies, plus you need a free approach to the shelves. For example, for four family members you need a storage area of 6 m² and a volume of 15 m³. The thickness of the walls must withstand soil pressure. When using brick, this figure is at least 25 cm. Secondly, it is necessary to provide for the location of the entrance, stairs, artificial lighting, ventilation and other details that make the storage easier to use.

You can build a round cellar yourself using cinder blocks, bricks, or pour monolithic concrete walls. The most profitable option is to use red brick, since all work can be done alone.

The only disadvantage of all round cellars is the inconvenience of making shelves. In factory caissons they are already provided by the manufacturer, but inside a brick storage facility you will have to make the shelves yourself. But, if the owner is satisfied with this, a round basement can be safely installed on your site.