Content

Insulating a well made of concrete rings is an important, and sometimes even necessary, procedure. Ignoring thermal insulation measures will lead to the fact that in winter you can be left without water supply. In addition, defrosted communications will have to be restored, which will lead to additional costs.

Does water in a well freeze?

Previously, no one thought about insulating the heads installed on the water supply source. The structures were made of wood. The material has excellent thermal insulation properties, due to which the water never froze. Modern heads of water supply sources are made of concrete rings. Reinforced concrete structures are used for sewerage, wells, and drainage wells are constructed from them. Concrete has high thermal conductivity. The ring will freeze like the ground.

However, to find out whether a concrete structure needs to be insulated, two important factors are taken into account:

- soil freezing level;

- the level of the water surface or communications located in the mine.

The level of soil freezing varies from region to region. For the south, this value is limited to 0.5 m. In the northern regions - from 1.5 m and more. The indicator for temperate latitudes ranges from 1 to 1.5 m. If the water surface or the water supply equipment installed in the mine is located above the freezing level of the soil, then the water will certainly freeze. Such a well needs to be insulated.

Is it necessary to insulate a well?

Even if the well is used only in the summer at the dacha, refusing to insulate it for the winter is considered a gross mistake. Nothing will happen to a wooden structure, but a concrete structure will bring an unpleasant surprise.

The most common problems:

- When water supply from a well runs inside a mine, ice plugs will appear in the pipes at subzero temperatures. The expansion will rupture the pipeline. If the pumping equipment is still installed, it will be damaged after the ice plug breaks.

- Freezing of water inside the well itself or in the soil adjacent to the rings creates a large expansion. Concrete structures shift. This results in depressurization of the shaft walls.

- A similar problem occurs when water freezes between the seams of the rings. The joints are destroyed. Dirty water from the ground begins to seep into the mine.

In the summer, all problems that have arisen will have to be eliminated. In addition to high labor costs, repairs will cost the owner dearly.

How can you insulate a well from freezing?

For thermal insulation of concrete rings, a material that does not absorb water is suitable. There is no benefit from loose insulation. It will do more harm.

The most suitable insulation materials are:

- Polystyrene foam is most often used for insulating wells. Its popularity is explained by its low thermal conductivity and water absorption. Polystyrene foam is not expensive, easy to use, and resistant to deformation during ground movement. A big plus is the ease of installation. A special shell is produced for concrete rings. The foam elements have a semicircular shape. To insulate the shaft, it is enough to glue them onto the concrete surface of the ring, secure them with umbrella dowels, and wrap the entire structure with waterproofing material. When the insulation of the well for the winter with your own hands is completed, the pit around the rings is covered with soil.

Important! Polystyrene foam has a huge disadvantage. The material is damaged by rodents and they make nests in the insulation for the winter. - Extruded polystyrene foam is an analogue of polystyrene foam, but has better characteristics. The material has lower thermal conductivity and resistance to heavy loads. Expanded polystyrene is ideal for insulating concrete structures, but it is more expensive than polystyrene foam. Thermal insulation is produced in slabs. It is optimal to use material with a width of 30 cm. The slabs can be laid tightly on the surface of the concrete ring. The insulation technology is the same as in the case of polystyrene foam. The joints between the plates are covered with polyurethane foam.

- Cellular polymer insulation is produced in rolls. The material has flexibility, low thermal conductivity, is resistant to moisture and heavy loads.A popular representative of rolled thermal insulation is isolon and its analogues, for example, penolin or isonel. There are brands of self-adhesive polymer insulation. If there is no adhesive layer, the insulation is fixed to the surface of the concrete ring with glue for external use. The joints are taped to prevent moisture from seeping under the insulation. After wrapping the ring, the trench around it is filled with soil.

- The modern and most reliable insulation is polyurethane foam. The mixture is applied to the surface of the concrete ring by spraying. After hardening, a durable shell is formed that does not require additional waterproofing. The insulation can withstand heavy loads, is plastic, and has low thermal conductivity. Polyurethane foam is not damaged by rodents and insects. The only drawback is the high cost. To insulate a well at your dacha, you will need special equipment. It is not profitable to buy it for one job. We will have to hire specialists from outside.

- Among the listed insulation materials there is no mineral wool. The material is very popular, but it is not suitable for insulating wells.

Mineral wool will last well in dry environments. The outside of the well is covered with soil, which gets wet when it rains or melts snow. Even reliable waterproofing is not able to protect mineral wool. Thermal insulation will become saturated with water and lose its properties. In winter, wet cotton wool will freeze and cause more harm than good to concrete rings.

How to insulate a well for the winter with your own hands

There are two ways to insulate a well: during its construction or a ready-made structure. The first option is optimal and requires less labor.If the well has already been built, for thermal insulation it will have to be dug to a depth below 50-100 cm from the freezing level of the soil.

The video shows an example of how you can insulate a well made of concrete rings with your own hands using foil-coated material:

Well insulation

When the water supply is provided from a well, a caisson is placed above the mouth of the excavation. In homemade construction, the structure is often made from concrete rings. The structure is a regular shaft with a ladder for descent. Inside there is pumping equipment, a hydraulic accumulator, filters, shut-off valves, pipelines and other automation components.

The head of the caisson can protrude onto the ground surface or be completely buried. However, in any case, without insulation it will freeze. Even in a buried structure, the upper part of the shaft cannot be located below the ground freezing level.

Thermal insulation measures for concrete rings can be carried out in two ways:

- If a shaft made of concrete rings has reliable waterproofing on the outside, insulation of the well with polystyrene foam is done from the inside with your own hands. The walls are covered with several layers of thin slabs, since it is easier to give them a semicircular shape. Rolled foam works great. The disadvantage of internal insulation is the reduction of space inside the well. In addition, foam is easily damaged during equipment maintenance.

- External insulation is carried out in three cases: if the shaft is poorly waterproofed from rings, if bulk thermal insulation is used, or if there is a need to prevent a decrease in the internal space. Polystyrene foam is less suitable for such work.It is optimal to insulate the well with polystyrene foam or polymer insulation with a foil coating.

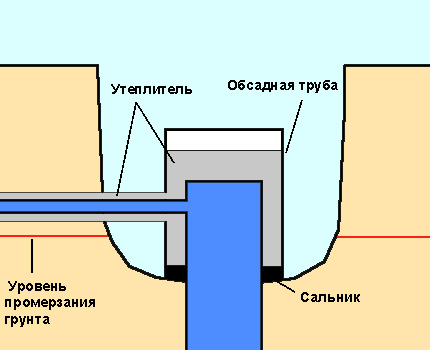

There is another reliable, but complicated method. To insulate the wall, the well is completely dug out. The mine is fenced off from the ground with a casing pipe. Its diameter is greater than the diameter of the concrete rings by 2 thicknesses of thermal insulation. This is the only option where you can use mineral wool. An important condition remains the organization of reliable waterproofing.

The fact is that the insulation will have to be pushed into the gap formed between the inner wall of the casing pipe and the outer surface of the concrete rings. The use of foam plastic or sprayed insulation is irrelevant here. It is impossible to densely fill the space with materials. The mineral wool is pushed in so tightly that the possibility of voids being formed is eliminated.

How to insulate a water well for the winter

Inside the water well there are usually shut-off and control valves and emergency drain valves. To prevent the unit from freezing, it needs to be insulated. There are three ways to insulate a water well:

- Insulation from the inside. The method is used for wells for technological purposes. In the version with water supply, it is enough to insulate the hatch.

- Ground thermal insulation on the outside. The method is based on insulating a part of the well located above the ground level.

- Underground thermal insulation on the outside. The method is based on digging a well shaft to the entire depth of immersion in the ground and attaching insulation to the rings.

To insulate the hatch, it is necessary to make an additional cover of such a diameter that it fits tightly inside the shaft made of reinforced concrete rings. There are many options. The lid is knocked together from boards, cut out of plywood, polystyrene foam boards. Be sure to come up with handles made of wire or other material to make it easier to lift.

A lid made of two halves is considered an excellent design. It is more convenient to lay it down and remove it from the shaft. Place the lid deep inside the well at a level below the freezing level of the soil. Under it you will have to attach limiters to the inner wall of the ring. The top of the well is covered with an ordinary hatch. The inner cover will not save the shaft from flooding with rainwater.

External above-ground insulation of wells is performed using penoplex or polystyrene foam. The concrete walls of the ring are covered with shells and the thermal insulation is protected with decorative finishing. Typically, the role of protection and additional thermal insulation is played by a wooden cap. The structure is assembled from timber and boards. A door is provided on the head that replaces the hatch.

With external underground insulation, the well is dug to a depth below 1 m of the soil freezing level. The concrete surface is treated with a primer, waterproofing is installed, and expanded polystyrene slabs are attached. The thermal insulation is covered with another layer of waterproofing on top, and the soil is backfilled. The part of the insulated shaft protruding above the ground surface is lined with bricks. You can install a wooden head in the same way as the previous method.

How to insulate a sewer well for the winter

Thermal insulation of a sewer well is no different from the activities carried out for water supply.If the level of soil freezing is small, it is enough to install a wooden cap over the ring shaft. It is not wise to make an inner lid. It is inconvenient to use it in a sewer well. In addition, the lid may become flooded with sewage.

For cold regions where deep freezing of the soil is observed, the method of external underground thermal insulation is acceptable. The mine is dug, and first of all, reliable waterproofing is installed. If sewage from the well penetrates through the joints between the rings to the insulation, it will disappear. Further steps include attaching polystyrene foam boards or spraying polyurethane foam. After backfilling the soil, the upper part of the well is covered with a wooden cap.

The video shows an example of well insulation:

Insulation of a drainage well

At most dachas, drainage wells are not used in winter. Water has been pumped out of the mine and equipment has been removed. Such structures do not require thermal insulation. It's simply not needed.

There is no need to create an insulated well at the dacha if the closed-type drainage system is located below the freezing level of the soil. The water here will not freeze at extremely low temperatures.

Thermal insulation is in demand when the drainage system operates year-round and the filtration drainage well is not deep. Insulation is carried out exactly as for sewerage. You can simply sprinkle the outside of the rings with gravel. To do this, the mine is dug. The walls of the pit are covered with geotextiles. The entire space is covered with gravel. Do not forget to insulate the supply drainage pipes.

Tips and tricks

Typically, the temperature inside an insulated shaft in winter is maintained within + 5 OC. This is enough for the normal functioning of any system. If it happens that the insulation of a well made of concrete rings is destroyed by rodents, the water will not immediately freeze. It may be slightly frosty. The first sign of danger is a decrease in system performance. You immediately need to open the hatch and assess the situation. Stuck pipes can be easily thawed by pouring hot water. A directed stream of hot air from a hairdryer or fan heater gives a good effect.

To survive until the spring repair of thermal insulation, the pipeline inside the well is covered with rags or mineral wool. You can hang a heating cable on the walls of the shaft and turn it on periodically during severe frosts.

Conclusion

Insulation of a well made of concrete rings of any type occurs practically according to the same principle. It is better to carry out this procedure immediately at the stage of its construction and laying communications, otherwise you will have to do extra work.