Content

In a private yard, a barn is needed as a storage room or for keeping animals. Often this utility structure is built from used materials or using what is left after the construction of the house. The dimensions and design of the shed are determined by its purpose. Let’s say that to store equipment it is enough to build a small, cold outbuilding, but you need to keep a large number of poultry in a spacious, insulated building. Now we will look at how to build a barn with your own hands from wood and foam blocks, and also present several options for drawings of an outbuilding.

Deciding on the location of the shed

The location for installing the shed is usually chosen further from the residential building. It is advisable that it be elevated, otherwise the utility block will constantly be flooded when it rains. In general, before choosing a place for construction, you need to look at the projects at least on the Internet, and then decide on the intended purpose of the outbuilding.

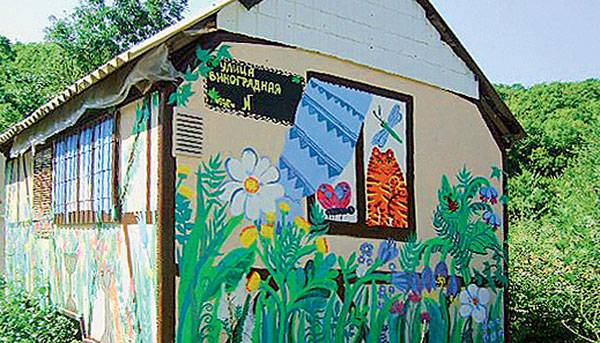

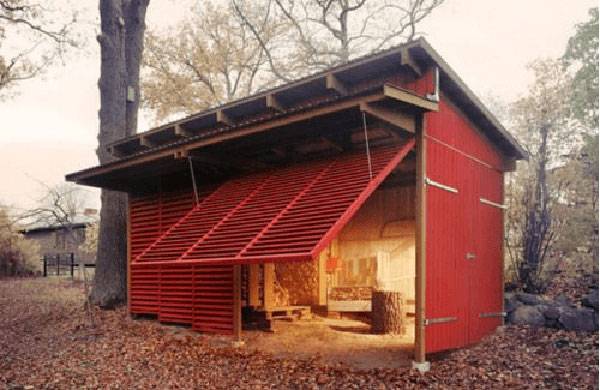

The photo shows examples of beautiful utility units for storing equipment. Such a building can be installed in a prominent place. It will even become a decoration for the site.You just need to try to decorate the barn so that it matches the architectural ensemble. If you plan to make a barn from blocks or used materials to raise poultry in it, then such a building must be hidden further from public view. In addition to the fact that the shed will spoil the interior of the yard with its appearance, the bird will emit an unpleasant odor.

Examples of barn designs

Before building a shed with your own hands, you need to draw a drawing. The diagram indicates the dimensions of the future building. This will help calculate the required amount of material. However, even before drawing up the project, you need to decide on the target direction of the barn. For example, capital construction requires more capital investment and labor, but a temporary utility block can be quickly assembled from scrap materials.

It is important to decide on the roof of the utility block. On an outbuilding you can install a single- or gable roof. Each roof option requires certain financial investments, skills, and labor costs. If you need a room for poultry, firewood storage, a toilet or an outdoor shower, it is wise to get a combined building.

The choice of material depends on the target direction of the utility unit. Typically, sheds are built from brick, wood or foam blocks. Further, we offer several projects for outbuildings. Maybe you'll like some of them.

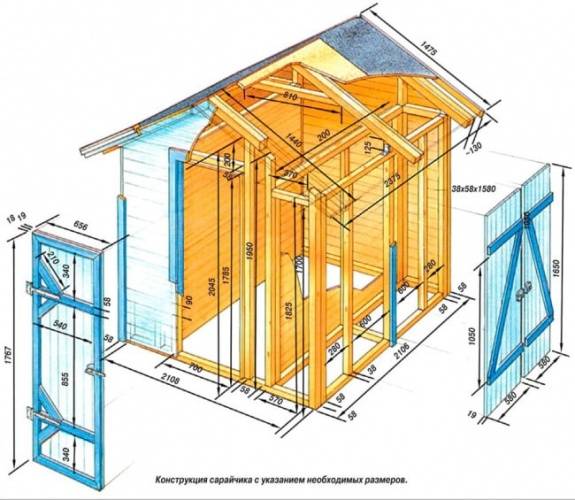

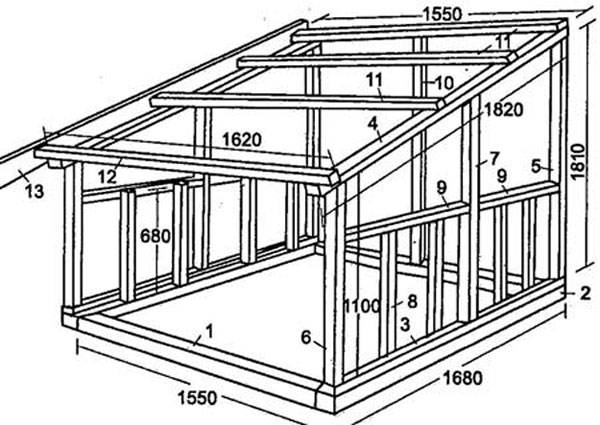

It is difficult for an inexperienced person to draw up a drawing of a utility unit on their own. This photo shows the proposed project frame barn with a gable roof. Assemble it according to the specified dimensions, if the dimensions of such a building satisfy you.

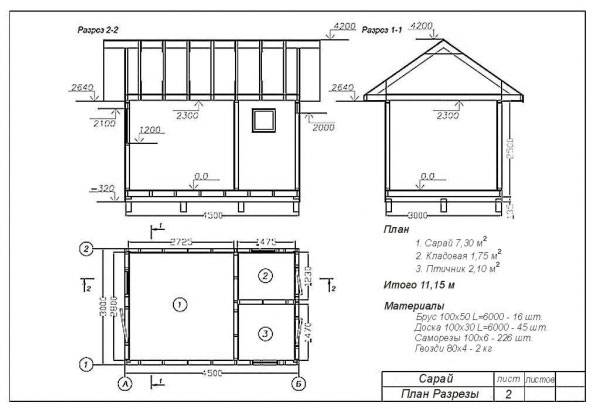

For the next project, we assemble a frame utility unit, divided into three compartments.Inside you can organize a poultry house, pantry, woodshed, summer kitchen or other premises as needed.

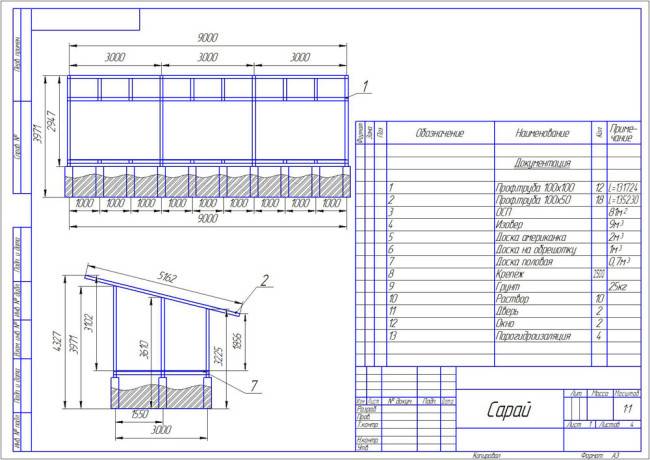

When it is decided that we are building a barn only for livestock, you can use the following proposed project.

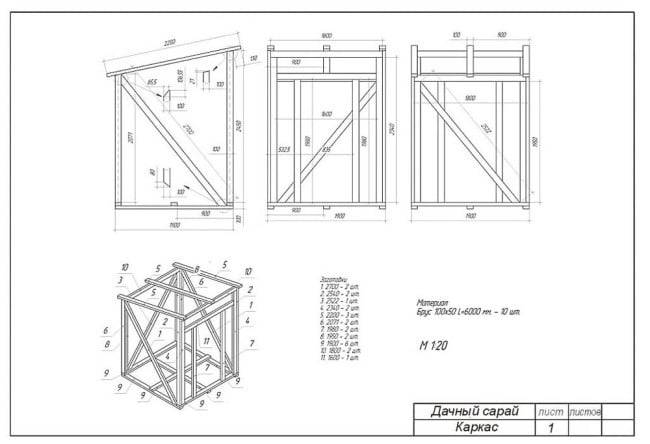

You can organize an outdoor shower, toilet or storage room in a small utility room. It can be assembled according to the presented drawing of the frame building.

It is better to assemble all temporary sheds using frame technology. The general view of the structure is shown in the photo. You can leave the frame dimensions or calculate your own.

Deciding on the type of foundation for the shed

The choice of foundation type depends on what type of building will be built. Heavy sheds with brick or block walls are built on concrete strips. It is reasonable to place frame utility blocks on a columnar base. Now we will take a step-by-step look at how to make your own foundation for your shed.

Strip foundation for utility block

Reinforced concrete tape can also be poured for a frame shed. Although for such buildings it is reasonable to equip such a solid foundation with large dimensions. Pouring a concrete strip requires a lot of labor and financial investment. Typically, such a foundation is made for brick or block sheds.

A step-by-step guide to constructing a concrete strip for a utility block looks like this:

- The contours of the future foundation are marked on the site. For a shallow foundation, dig a trench 40–50 cm deep. If soil heaving is observed, then the depth of the trench is increased to the level of soil freezing. Usually, a depth of up to 80 cm is enough. The width of the reinforced concrete tape for a frame utility block is taken within the range of 25–30 cm.For brick and block sheds, the width of reinforced concrete strips is made 100 mm greater than the thickness of the walls.

- The bottom of the trench is covered with sand and crushed stone 15 cm thick. Formwork equal to the height of the base is assembled from boards. It is installed on top along the perimeter of the trench, and the bottom and side walls are covered with roofing felt. If the height of the formwork is more than 50 cm, the side walls are reinforced with temporary supports. Particular attention should be paid to strengthening the corners.

- To ensure that the tape has good bending resistance, a box-shaped reinforcing frame is assembled inside the trench. Reinforcement 12 mm thick is tied with knitting wire. Rods cannot be welded.

- The tape for the shed is poured in one day, otherwise a monolithic base will not be obtained. You will need to prepare a lot of solution, so it is better to use a concrete mixer.

After at least two weeks, the concrete will gain about 70% strength. On such a foundation you can already begin to erect the walls of the barn.

Columnar base for utility unit

When building small frame sheds, a columnar foundation is most often installed. The cabinets can withstand light construction and do not require much building material.

Let's look at the step-by-step steps to complete the work when laying red brick pedestals:

- Adhering to the markings, they dig holes 70 cm deep. They must be placed in the corners of the future building in increments of maximum 1.5 m. If the width of the utility block is more than 2.5 m, then intermediate pedestals are additionally provided.

- A 15 cm layer of crushed stone and sand is poured onto the bottom of each hole, after which they begin laying red bricks on concrete mortar.

Having built all the cabinets, make sure that they are on the same level. If necessary, low pillars are built up with concrete mortar.

To build cabinets for a frame utility block, you can use hollow concrete blocks. For them, holes are dug in 1 m increments. The step-by-step instructions for laying blocks are no different from working with bricks. Only the voids in the blocks need to be filled with mortar during laying.

Concrete blocks can additionally be laid under the floor beams of the utility block. They will not allow the floor to sag when exposed to heavy loads.

Columnar wooden foundation for a temporary shed

Any person who built temporary huts for household needs did not lay a strong foundation for them. So for our utility block we can build a foundation from logs. If the workpieces are well treated with waterproofing, then such a temporary structure will last up to ten years.

Let's look at how the stage-by-stage laying of such a foundation occurs:

- The materials you will need are larch or oak logs 1.5–2 m long and 30 cm in diameter. The part of the pillars that will be in the ground is treated with bitumen and wrapped with two layers of roofing felt on top.

- Holes are dug under the logs. The bottom is covered with a 150 mm layer of crushed stone or gravel. All logs are installed in the holes, after which the gaps are simply pushed in with soil. It is allowed to fill the holes with concrete or fill them with a dry mixture of sand and cement.

The lower frame of the frame shed is simply nailed to the wooden foundation.

Instructions for constructing a frame shed

First, let's look at building a shed using frame technology. Even one person can handle this kind of work.

So, guided by the project, we begin to build a frame shed:

- First, you need to assemble the main frame of the utility unit from timber with a wall size of 100x100 mm. The frame posts will be attached to it.To connect the elements at the corners of the frame, cuts are made at the end of the beam to half its thickness, that is, 50 mm.

- Regardless of the design, the foundation is covered with two sheets of roofing material. The frame of the utility block is nailed to the wooden base with long nails. Fixation to the concrete strip occurs with anchor pins.

- Now you need to fix the logs to the frame. A board with a cross section of 50x100 mm is laid in 600 mm increments. The top edge of the joists must be flush with the surface of the frame, otherwise it will be difficult to lay the floor in the barn. An insulated shed requires a double floor. To make it convenient to line the beams from below with boards or OSB, do not rush to fix the frame to the foundation. The entire structure can be secured after attaching the subfloor.

- When the lower frame of the utility unit is already securely fixed to the foundation, they begin to install the racks. They are made from timber of similar thickness. It is optimal to install racks 3 m high in front of the barn, where the entrance door will be, and 2.4 m high in the back. The height difference of 600 mm will allow you to organize the slope of the shed roof of the utility block.

- The racks are placed at the corners of the frame, at the locations of partitions, door and window openings, as well as evenly along the wall in increments of maximum 1.5 m. The workpieces are secured to the frame with metal mounting angles. For frame rigidity, all racks are reinforced with jibs, which are installed at an angle of 45O. The instability of the frame can be reduced by installing temporary supports.

- In the places where the door frame and window frame are installed, horizontal jumpers are nailed. The top trim is attached to the racks with the same mounting angles. The frame is assembled from timber of similar thickness, because it will support the entire roof.

- Now it’s time for the barn’s floor beams.They are made from boards with sides measuring 50x100 mm and laid in 600 mm increments. At the back and front of the frame, the beams should form an overhang about 500 mm wide.

- The sheathing is nailed on top of the joists. For solid roofing, sparse lathing made of unedged boards 25 mm thick is used. Under a flexible roof, a solid base is made of plywood or OSB.

This completes the skeleton of the frame barn. Now all that remains is to cover it with boards or clapboards, lay the floor and lay the roofing chosen by the owner.

The video shows the production of a frame structure:

Instructions for building a shed from foam blocks

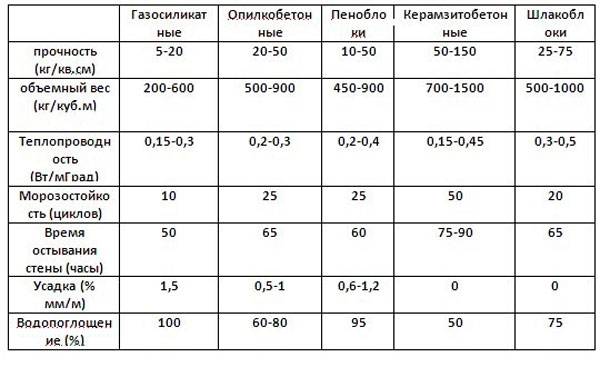

Recently, foam blocks have been used more often than bricks for the construction of sheds. The popularity of the material is due to its low weight, good thermal insulation properties, and the ability to “breathe”. Foam blocks are larger in size than bricks, which speeds up the process of laying barn walls. It should be taken into account that the blocks have several varieties that differ in their composition. The characteristics of the material can be seen in the table.

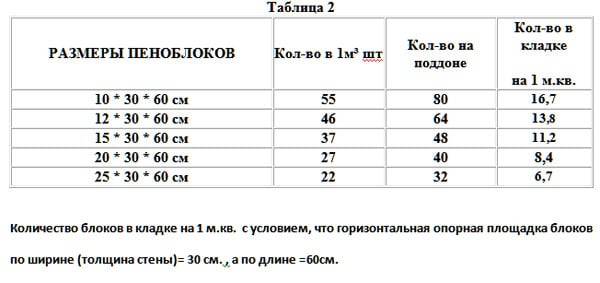

To calculate the required number of foam blocks for your shed, you need to know their size. The data is shown in the table.

Foam blocks can be laid on concrete mortar, but it is better to use glue. The construction of the walls of the barn begins from the corners. A strip or slab foundation is suitable for such a capital structure. You can install piles, but this will be expensive for the owner.

When all four corners are level and plumb, a rope is pulled between them. Laying the walls continues along the cord from the corners. It is important to observe the dressing of the seams in the rows, otherwise the design will turn out shaky.

The adhesive or concrete solution is applied with a notched trowel.The foam block must be lubricated generously so that there are no areas left without solution. After laying the block, the excess is cleaned off with a trowel or even spatula.

The walls of the barn are made at least 2 m high. Next, a frame made of timber - a mauerlat - is laid around the entire perimeter. The rafter system of the shed's lean-to or gable roof will be attached to it. The second roofing option is more difficult to manufacture, but allows you to organize an attic in the utility room for storing things.

Waterproofing must be placed under the Mauerlat. On a large barn, the slate roof puts a lot of pressure on the walls. To distribute it evenly, it is often practiced to pour a monolithic reinforced concrete belt on the top row of walls.

When the rafter system of the shed is installed, the sheathing is nailed, waterproofing and roofing are laid.

In conclusion, we invite you to look at a selection of photos of country sheds.

If you get creative, you can decorate the barn so that it becomes a landmark on your property.