Even before starting construction of the shed, you need to decide on its purpose. The utility block for storing equipment can be made cold with thin walls. If you plan to build a barn for the winter where poultry or animals will be kept, then you need to take care of insulating the room.

How to build a warm shed

When building a winter shed, it is advisable to immediately select materials that have good thermal insulation properties. It is optimal to build walls from timber, foam blocks or gas blocks. These materials retain heat indoors so well that there is no need to use thermal insulation. The only drawback is the considerable financial costs.

It is possible to build a winter shed at minimal cost, but it will take some work. If you mix cement with sawdust or small shavings, you get excellent blocks for walls. They are called arbolite. The benefits of producing such material are obvious:

- The light weight of the blocks allows walls to be erected on a lightweight foundation;

- Wood shavings have excellent thermal insulation properties, so there is no need for additional wall insulation;

- Cheap material. The shavings can be taken free of charge at any sawmill. You only need to buy cement, and its consumption is only 10% of the mass of wood waste.

It is better to make the floor of the winter shed double from boards with thermal insulation. It is imperative to provide an insulated ceiling. It is also important to take into account one rule. All winter sheds intended for keeping poultry and animals have low ceilings. It is easier to heat such a room, and the heat evaporates from it more slowly.

The video shows the thermal insulation of an outbuilding:

We transform an old cold barn into a warm room

When there is already a ready-made shed in the yard, but it is old and cold, then it is not worth dismantling it. It will be cheaper to reconstruct the building. After all, when disassembled, most of the building material will become unusable. Now we will look at how to insulate a barn cheaply but reliably so that it can be used in winter for keeping poultry.

Making double walls from boards

So, on the site there is an old wooden shed with large cracks in the walls. They need to be patched first. To do this, take a board 15–20 mm thick and nail it along all four walls. If the sheathing occurs outside, then the fastening is done horizontally with an overlap. The edge of the top board should overlap the bottom board. You will get a kind of Christmas tree. Water from any heavy rain will not be able to penetrate under the casing.

From the inside of the room, sheathing posts are nailed vertically to the walls. In the future, the gap between the two walls will be filled with sawdust at least 20 cm thick, so the width of the sheathing elements must be taken the same. However, it is difficult to find a board 20 cm wide, and it is expensive. It’s easier to take the slats and secure them to the wall with hangers at the appropriate distance.

Next, we begin covering the walls. The boards are nailed to the sheathing, starting from the floor. It is better to place sawdust between the sheathing in plastic bags. The film will protect the insulation from dampness. To make this convenient, nail the number of boards on the wall as needed to form a pocket at the height of the bag.

So, the first pocket for the entire length of the wall is ready. An empty bag is inserted into the gap one by one, after which it is pressed tightly with sawdust. After filling, the edges are sealed with tape. There should be no gap between the bags of sawdust, otherwise the work will be useless.

When one row is ready, sew another board until a new pocket is formed. The process is repeated until all walls are insulated. Right at the ceiling, you will first have to fasten bags of sawdust to the wall, and then press them down with sheathing.

Insulation of walls with shingles

An old, reliable and proven method is to insulate the wooden walls of a barn with shingles. Costs are practically zero. You will only have to buy a thin strip. If there is no money for this material, then you can cut thick rods from vine or willow.

So, we insulate the winter shed using the old-fashioned method:

- The slats are nailed at an angle to the wooden wall from the inside of the shed.To be safe, you can nail the second row on top, only diagonally in the other direction. Then you will get diamonds on the wall.

- After covering all the walls with shingles, they begin to prepare the solution. The clay should already be soaked two days before starting work. Now you need to add wood shavings or straw to it, then knead thoroughly.

- The finished mortar is spread over the shingles with a trowel, starting from the bottom of the wall. Nailed slats are a kind of beacons. Using them as a guide, approximately the same thickness of mortar is applied to all the walls of the winter shed.

- After applying the plaster, the walls are allowed to dry. There are bound to be a lot of cracks. To grout them, hammer in a solution of clay and sand in a 1:2 ratio. When the dry walls of the barn remain without a single crack, they begin to whitewash with lime.

This old method of insulation is very labor-intensive, but is considered the cheapest.

Thermal insulation of barn walls using purchased materials

If the region experiences severe winters, the insulation of the shed walls needs to be taken more seriously. For these purposes, purchased thermal insulation is used. You can use polystyrene foam, but rodents love it, plus the fire hazard of the material and other negative qualities. Mineral wool is ideal for the wooden walls of a barn. It is better to avoid rolled material due to its ability to caking. It is optimal to give preference to slabs made of basalt wool.

Work begins with securing the sheathing, but first the wall is covered with waterproofing material. It will protect the insulation from moisture. As a sheathing, you can simply nail slats vertically to the wall with a width slightly larger than the thickness of the insulation.Basalt slabs are placed inside the resulting cells, starting from the floor of the barn. They must be recessed at least 1 cm to create a ventilated gap between the thermal insulation and the wall sheathing. When all the cells are laid, the insulation is covered with a vapor barrier. To prevent the slabs from falling out of the cells, they are secured with wooden planks.

Now all that remains is to nail the cladding material. A regular board, wooden paneling or plywood will do.

Installation of heated floors in a barn

Of course, a “warm floor” system in a winter barn is rarely found, since it is very expensive. We will also insulate the floors using a simple method. If an old wooden shed is simply standing on the ground, the floor level inside needs to be raised by 10–15 cm. To do this, make a sand embankment. It would be good to add expanded clay if available. Now you will need to mix a lot of clay solution with sawdust. The pouring of the barn floor begins from the far wall, moving towards the exit.

It is advisable to pour a layer at least 10 cm thick. When the screed dries, cracks may appear on the surface. To grout them, prepare a liquid clay solution. The floor surface can simply be wiped down with a rag. The main thing is to constantly add liquid clay so that the solution penetrates into the cracks.

If the barn is built on a strip foundation, capital insulation of the floor begins with the blind area. To do this, a trench is dug around the base of the building, into which polystyrene foam, covered on both sides with waterproofing, is laid. The same insulation is attached to the base, after which a screed is poured around the foundation or a blind area of crushed stone is poured. Inside the shed, waterproofing is laid on the floor, then polystyrene foam and waterproofing again. A concrete screed is poured on top.

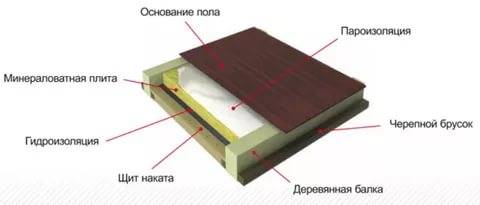

IN frame sheds, installed on a pile or columnar foundation, make a double floor from boards or OSB. The gap between the lags is filled with foam plastic, mineral wool, or simply covered with expanded clay. It is important not to forget to lay waterproofing under the insulation and cover it with a vapor barrier on top.

We insulate the barn ceiling

In a winter shed, it is imperative to insulate the ceiling. This is where most of the heat goes. If it is not there, then you need to nail a board, plywood or OSB onto the floor beams from below. A vapor barrier is laid on top of the sheathing from the attic side, and then any insulation. This is where you can save money. Straw, gravel, and sawdust have excellent thermal insulation properties. Any of these materials can simply be scattered between the beams.

Video of ceiling insulation with sawdust:

Insulation of doors and windows of a winter barn

Often the door of a rural barn looks like the one shown in the photo. That is, a shield made of boards with large cracks hangs on hinges. This is unacceptable for a winter shed. First, the door needs to be hung on reliable hinges, because after insulation it will become heavier.

Next, a strip is nailed on the outside around the perimeter of the door. 2-3 jumpers are placed inside the frame to form cells. This is where you need to put the mineral wool. The insulation can be covered with boards on top, but the door will become heavy. During rain, such cladding will allow water to pass through. In addition to the fact that the insulation will become saturated with moisture, the structure will become even heavier and can even tear out the hinges. It is better to cover the outside of the door with a sheet of corrugated board, and from the inside of the shed you can close the gaps between the boards with fiberboard or thin plywood.

To reduce heat loss through the windows, two glasses are installed in the winter barn.Moreover, it is advisable to stick them to the frame using silicone or any putty. If there are cracks around the window, you can easily caulk them with tow and nail platbands on top.

Results

After insulating all elements of the barn, the outbuilding can be used in winter. In severe frosts, birds or animals are heated with an infrared heater.