Content

- 1 General requirements for feeders for pigs and piglets

- 2 Types of feeders

- 3 How to make pig feeders with your own hands

- 4 Making your own bunker feeder for pigs and piglets

- 5 How to make a pig feeder from a plastic barrel

- 6 How to make a pig trough from a gas cylinder

- 7 Feeders for piglets and pigs from pipes

- 8 How to make a trough for pigs and piglets from wood with your own hands

- 9 Installing feeders in a pigsty

- 10 Original ideas for pig feeders with photos

- 11 Conclusion

Feeders for pigs in a simple design are a spacious container divided into compartments for each head. Bunker-type models are considered improved, allowing for automatic feed supply. It is not difficult for pigs to build any feeder themselves, which household owners do with success.

General requirements for feeders for pigs and piglets

Before manufacturing and installing a feeder in a pigsty, you must familiarize yourself with a number of sanitary requirements:

- The installation location in the pigsty is chosen to be accessible, so that it is convenient to pour feed into the pigs, clean them from residues, and wash them.

- The trough is provided with reliable fixation. Pigs should not turn it over or deform it with blows.

- The feeder is arranged so that pig excrement does not get inside.Organic waste contains parasite larvae that cause dangerous diseases.

- Separate containers are provided for pigs for dry, liquid food and water.

- Leaky troughs must not be used. Liquid feed leaks through the cracks, the humidity inside the pigsty increases, and unsanitary conditions arise.

- For each age of pigs, troughs with appropriate side heights are selected. Maintain an angle of inclination so that the feed flows to the front wall.

Small piglets are born weighing about 1 kg. If the diet is followed, individuals of good breeds at six months of age are able to gain weight up to 100 kg. The weight of a breeding boar or sow reaches 300 kg. Along with gaining weight, the size of pigs, in particular the head, increases. To make it more convenient for the animal to get food, a certain length of trough is allocated for each age:

- milk baby – 15 cm;

- for young animals up to 3 months old - 20 cm;

- for individuals 6 months old left for fattening – 25 cm;

- age category of pigs from 7 to 10 months – up to 35 cm;

- feeder length for sows – up to 40 cm;

- breeding boar - from 40 to 50 cm.

The height of the sides of the trough for dairy babies is made up to 10 cm high. The parameter for adult pigs is in the range of 15-25 cm.

Types of feeders

Conventionally, all existing feeders are divided into two groups.

By method of use:

- stationary models for pigs are securely fixed and cannot be moved;

- mobile models are in demand on large farms for uniform feeding of the herd;

- individual models are placed inside a box for one animal, for example, a sow;

- group models are designed for simultaneous feeding of several pigs.

By device:

- ordinary feeders are made in the form of a simple trough, and sometimes pigs use any container at hand;

- Hopper feeders for pigs are more complicated, but they allow automatic feed supply.

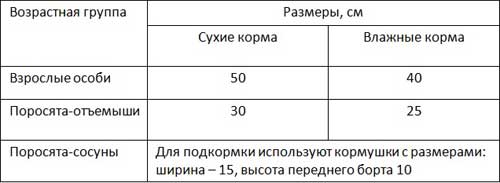

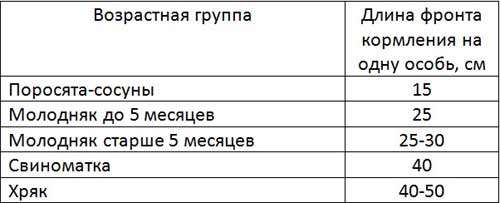

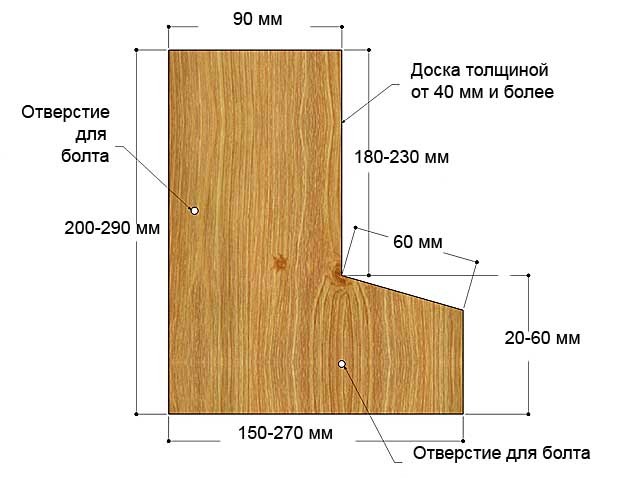

Feeders vary in size. They can be narrow, wide, shallow and deep, with or without dividers. When making a feeder for piglets with your own hands, photos of tables with dimensions will help you build the optimal design.

Width parameters table:

Length parameters table:

Table of drinker parameters:

The video will help you make a pig feeder with your own hands according to all the rules:

How to make pig feeders with your own hands

The process of making a trough is simple. But an automatic feeder for pigs is more complicated. Here you will need drawings with exact dimensions.

What materials are suitable for manufacturing

The most popular materials are metal and wood. Each of them has its pros and cons. Ferrous metal quickly rusts and rots in damp conditions. It is optimal to use stainless steel, but the design will be more expensive. Wooden troughs are made from 40 mm thick boards. The natural material is environmentally friendly, but pigs chew it. Food debris eats into the tree and bacteria multiply.

Making your own bunker feeder for pigs and piglets

Compared to a trough, making a bunker feeder for pigs is much more difficult, but it has great advantages. The design consists of a spacious bunker for filling feed. Its lower part with a slot is directed into the tray.A certain portion of the feed spills out from the hopper. When the pigs eat it, a new portion is automatically supplied to the tray.

Another advantage is the uniform feed supply. Pigs receive a certain amount of food. They eat it completely, and there is nothing left over to be scattered or contaminated. The presence of a spacious bunker allows you to make large supplies of food.

Making your own automatic feeder for pigs is beneficial if the farm contains at least 5 pigs. However, sometimes the design is used when fattening 2-3 animals. It is optimal to choose metal as the manufacturing material, but if there is no experience in welding, wood is used.

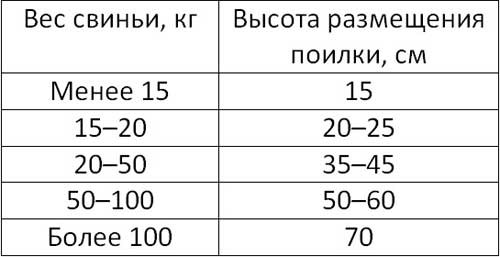

When assembling a bunker feeder for pigs with your own hands, it is advisable to have drawings on hand. Essentially, you need a diagram of one side shelf. The second element is an exact copy. The shelves are connected to each other by rectangular fragments. As a result, two containers are formed: a tray and a hopper. The photo shows the dimensions, but they can be changed depending on the age of pigs the automatic feeder is intended for.

To make a metal structure for pigs, you will need stainless steel about 3 mm thick, a grinder and a welding machine. The manufacturing process consists of several steps:

- Drawings are transferred to a sheet of metal. Using a grinder, cut out fragments of blanks.

- The parts are welded into a single structure. A sheet is welded to the bottom of the bunker at an angle. The device forms a gap from where dry food will be fed into the tray.

- A limit bar is installed near the hopper slot.

- The bottom of the tray is welded with a rectangular plate to form a container for food.

The structure is ground, removing sharp burrs and scale. Be sure to weld the fasteners so that the pigs do not overturn the feeder.

A wooden analogue of an automatic feeder for pigs is assembled according to a similar principle, only self-tapping screws are used for connection. The body elements are cut out of multi-layer moisture-resistant plywood using a jigsaw. To strengthen the connection, bars are placed at the joints. The elements are tightened with self-tapping screws. If the automatic feeder for pigs is supposed to be placed outside, the top of the bunker is equipped with a hinged lid. It is secured with furniture hinges.

A plywood automatic feeder is suitable for small piglets. Big pigs will easily break it. For adult individuals, the optimal material to use is boards with a thickness of about 40 mm.

How to make a pig feeder from a plastic barrel

Used plastic barrels are great for feeding pigs. The only requirement is that you cannot use containers that previously contained pesticides. The advantage of plastic is its resistance to corrosion. The containers are washed well, but pigs gnaw them, which is the only drawback.

For small piglets, a trough can be made by simply cutting out windows in the side of the barrel. The remaining strips will act as dividing bridges. The barrel is securely fixed to the floor so that it does not roll.

It is optimal to build a feeder for piglets with a wooden frame with your own hands. Adult pigs will not chew it quickly. A plastic barrel is cut lengthwise into two parts using a grinder. The frame is made from boards 40 mm thick.The halves of the barrels are inserted inside the frame.

If you plan to breed young animals, then it is optimal to split the barrel into two unequal parts. The larger half will go to the big pigs, and the smaller half will make a trough for the little ones.

How to make a pig trough from a gas cylinder

A trough for pigs is made from a gas cylinder according to a similar principle, only the container must first be properly prepared. First of all, make sure there is no gas by opening the valve. Condensation with a pungent odor may remain inside. The liquid is drained through an open valve by turning the container over. Disposal is carried out away from residential areas.

The cylinder valve is unscrewed or cut off with a grinder. Pour water inside, shake it thoroughly to remove any remaining condensation, and pour it into the designated area. The balloon is cut lengthwise into two halves using a grinder. The blanks are burned with fire and washed from soot. To make the pig trough shown in the photo with your own hands, the two halves are welded together with rods. Legs are welded to the bottom from the outside. If the trough of the two halves is too large for the pigs, use one part of the cylinder.

Feeders for piglets and pigs from pipes

If the farm has a piece of asbestos-cement or ceramic pipe with a diameter of at least 200 mm, it will make a good stationary trough for the pigs. First, cut the workpiece to the required length with a grinder. The next step is to spread the pipe lengthwise into smaller and larger parts. The first element is discarded. Most of the pipe will go to the pigs' trough.

The base of the feeder is poured into a concrete pigsty. A pipe is placed in the solution, the sides are closed with plugs.It is optimal to install a fitting on one side through which liquid will drain while washing the trough. Separating bridges for each pig are installed from reinforcement 15 mm thick.

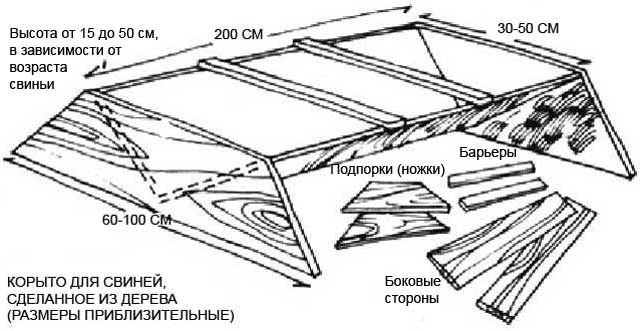

How to make a trough for pigs and piglets from wood with your own hands

The advantage of a wooden pig trough is its ease of assembly. In addition, wood tends to swell, which causes all the cracks to tighten. Even liquid food can be given to pigs in a wooden trough. The photo shows a detailed drawing. Sizes are selected according to the age of the pigs. The parameters are shown in the table above. Tools for the job will include a saw, a jigsaw, a screwdriver, and a hammer.

Manufacturing begins by cutting out fragments from a 40 mm thick board. If the trough is permanently fixed near the wall of the pigsty, then the rear side is made higher from the front to prevent feed from falling behind the feeder. When it is assumed that the pigs will approach from both sides, the height of both sides is made the same.

The cut blanks are folded into a single structure and tightened with self-tapping screws. Sharp edges are treated with sandpaper and burrs are removed so that the pigs do not get hurt. The working part of the trough is separated by jumpers made of polished bars with a cross-section of 40x40 mm.

Installing feeders in a pigsty

There are several options for the location of feeders:

- troughs are installed permanently for pigs;

- for two-way access of pigs in a large herd, mobile structures are arranged;

- when keeping up to three pigs in a box, a separate location for the feed dispenser is arranged;

- It is customary for a large number of pigs to be given space for group feeders.

The installation location is chosen at the stage of construction of the pigsty. It is advisable to separate the pig feeding unit in order to reduce its exposure to contamination. The troughs are installed at an arbitrary slight slope. The feed will move under one edge.

Original ideas for pig feeders with photos

In the household, troughs for pigs are made from anything that can be adapted. Metal containers are considered the best option due to their long service life. For little piglets, troughs are cut out of buckets, plastic bottles, and car tires. The do-it-yourself pig feeders shown in the photo are original, and anyone can make them in a couple of hours.

Conclusion

Feeders for pigs should be convenient for the animals themselves and the owner for maintenance. If all requirements are met, the piglets eat well and gain weight faster.