Content

In winter, in regions where there is a large amount of precipitation, the issue of clearing the roofs of buildings from snow is acute. A large accumulation threatens an avalanche, which could injure people. Hand tools help get rid of snow cover. There are many different types of scrapers and factory-made shovels. Many craftsmen have learned to use devices for snow removal from the roof to make yourself. Now we will review snow removal equipment that will help solve this problem in winter.

Snow shovels

With the arrival of the first snowfall, each owner of his yard goes outside with a shovel to clear the paths. There are many variations of this popular tool. Shovels are sold in different sizes:

- The most comfortable and lightweight snow removal models are made of plastic. The disadvantage of such shovels is their increased fragility in the cold or they simply break under heavy loads.

- Metal shovels are quite durable, but heavy. Wet snow will constantly stick to the scoop. But most importantly, steel tools can damage the roofing.

- Wooden shovels are more gentle on the roof covering. However, the service life of such a tool is not long.

- Aluminum shovels are lightweight, durable, and do not corrode. Some owners don't like them because of the noise they create when removing snow from the roof.

The advantage of using shovels when clearing snow from a roof is the availability and versatility of hand tools: the owner went out into the yard and cleared the paths, climbed onto the roof and cleared the roof of snow. There is a shovel in every yard. As a last resort, you can buy this tool for little money at your nearest store.

The disadvantage of using shovels is the heavy physical labor involved. On a roof with a soft roof, snow must be removed carefully, otherwise there is a risk of damage to the coating.

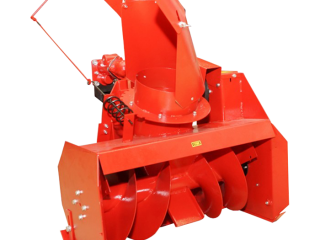

Modern snow shovel powered by electricity

An electric tool will help you quickly deal with snow accumulation on your roof. It is produced in the form of a small shredder with a long handle or a compact but more bulky machine. Both power tools are commonly used to clean flat roofs. You can try to drag the shredder onto a pitched roof with a slight slope, but such work is dangerous. In the private sector, it is advisable to use an electric snow blower to remove snow that has fallen from the roof near a building. Utility services use such equipment on the flat roofs of high-rise buildings.

The advantage of electric equipment is the ability to quickly clear the roof of any thickness of snow cover. Working with a shredder or machine is much easier than throwing snow with a regular shovel.

The main disadvantage is the inability to use an electric shovel on a pitched roof. The design of any such equipment requires the presence of an electric motor, which has an impressive weight. Pulling a shredder or car onto the roof is quite problematic. In addition, you will have to take care of a long cable. The wire must be constantly monitored so that it does not fall under the knives of the operating mechanism.

Despite all the shortcomings, electric shovels are the ideal tool for cleaning large flat roofs. A snow blower with a screw blade easily cuts off a layer of snow with an icy crust and throws it far to the side through an outlet sleeve.

A scraper is an excellent tool for clearing snow from pitched roofs.

It is impossible to clear snow from a pitched roof with an electric tool, and it is dangerous with a regular shovel. It is easy to fall off a slippery slope. It is best to clean a pitched roof from the ground. There is a special tool for this work - a scraper. Its design resembles a reduced-size scraper.

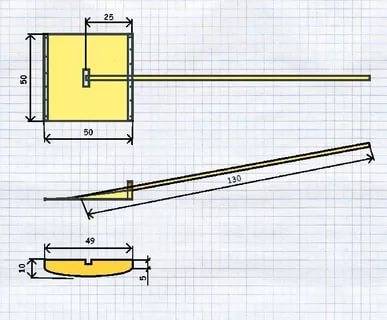

The basis of the scraper is a long handle that allows you to reach from the ground to the very ridge of the roof. The design of the scraper itself can have a different configuration, but usually it consists of an arc with a jumper. This frame is attached to the handle. A long strip of elastic, waterproof material is fixed on the jumper. During operation, a person pushes the scraper handle up the roof slope. The lower jumper of the frame cuts the layer of snow, and it slides along an elastic strip to the ground. The width and depth of the grip depends on the dimensions of the scraper.

The advantages of working as a scraper are obvious.This lightweight tool allows you to effortlessly clean a large pitched roof without having to climb onto it. By extending the handle, you can reach from the ground to the highest point of the roof. The snow slides along an elastic strip under the wall of the house and it is unlikely that it will fall on the head of a working person.

The disadvantage of the tool is its limited use. Apart from clearing the pitched roof of snow, the scraper cannot be used anywhere else.

The video shows how the roof is cleared of snow:

Making your own shovel

The design of a snow shovel is very simple. Such a tool can be assembled in a couple of hours from materials available at home.

The most common is plywood tools. Making a scoop occurs in the following order:

- Take a piece of plywood sheet. A square measuring 40x40 or 45x45 cm is cut out of it with a jigsaw.

- A board 10 cm wide and 2 cm thick is nailed to one side of the plywood sideways. This will be the back side of the scoop. The bottom of the board can be rounded with a plane. Then the scoop will be curved, as shown in the diagram. A small recess is cut out in the center of the side, which forms a seat for the cutting.

- The plywood end of the front part of the scoop is sheathed with a bent galvanized strip. Similar strips can be used to strengthen the rear side.

A metal scoop is made according to a different principle. Typically aluminum sheet or galvanized steel is used for manufacturing:

- A square is similarly cut from the selected metal sheet. Here you need to take into account the dimensions of the working canvas itself, plus the bends for the sides.

- The back element of the scoop can be cut from a board, as was done for the plywood counterpart. It’s easier to just bend all the sides out of metal. Then a hole for the handle is cut in the center of the rear element.

After any scoop design is ready, proceed to attaching the handle. The cutting can be bought new or removed from another shovel. One end of it is cut at an angle so that its end fits tightly to the plane of the scoop, strictly in the center. In this case, the handle itself should touch the seat on the rear side. The end of the handle is secured to the working plane of the scoop with a self-tapping screw, plus it is reinforced with a tin plate. If the back side was bent out of metal, then the handle is simply inserted through the drilled hole. The handle is fixed to the wooden board with a steel strip plate.

Homemade snow removal devices are exclusive. They can have the most unusual design. The main thing is that the tool does not pose a danger to the working person and the roofing itself.