Content

Clearing snow with ordinary shovels is quite difficult. For a woman, teenager or elderly person, cleaning the area from snow drifts sometimes turns into real hard labor. An electric shovel is designed to make such difficult work easier. for snow removal. This device will quickly and easily move even large white “caps” to the storage location, thoroughly cleaning the area. Power tools in various configurations can be purchased at a very reasonable price or made by yourself. Up-to-date information on how to choose an electric shovel or make one yourself can be found in the proposed article.

Basic elements and principle of operation of an electric shovel

A modern electric snow shovel has nothing in common with traditional equipment, except that the shape of these tools is a little similar. The design and technical characteristics of some models of electric shovels may differ, but the principle of their operation is similar:

- An electric motor with a power of 1000 to 1800 W drives the auger, which, while rotating, rakes up the snow.

- Under the influence of a powerful air flow, the snow collected by the auger flies out in a given direction 4-10 m to the side.

- The electric shovel is controlled using a long, rubberized handle with a start button.Some models are equipped with telescopic handles.

- Some electric shovels include a special brush that can be installed in the summer season to clean small debris from paths.

An electric shovel is a compact tool with a working width of 25 to 40 cm. However, the actual width of the surface being processed is slightly smaller. The tool can only remove freshly fallen snow, up to a layer of up to 40 cm. The productivity of various electric shovels varies from 80 to 140 kg/min.

To operate the electric shovel, you must have access to an electrical outlet. The cord of the tool itself is quite short, so for snow removal you need to stock up on an extension cord. It is worth noting the significant weight of the tool: on average, an electric shovel weighs about 6 kg. During operation, the shovel body should be kept 2-3 cm above the ground surface. This will help prevent damage to the instrument in case of an accidental collision with an obstacle. To avoid straining your arms and back, you should use models with small wheels on which you can rest the tool and move it freely. You can see the electric shovel and evaluate its work by watching the video:

Advantages and disadvantages of the tool

The main advantage of an electric shovel is that it can significantly facilitate a person’s work by quickly clearing the area after another snowfall. In this case, it does not matter at all what kind of relief the site has. However, the use of an electric shovel is limited by certain conditions:

- You can work with the tool at a temperature not lower than -250WITH;

- the area of the cleaned area should not exceed 6 m2, since the electric shovel is not intended for long-term continuous use;

- it will be possible to work with the tool only within the reach of the extension cord;

- an electric shovel cannot remove wet or compacted snow;

- The electric motor makes a lot of noise during operation, which causes some discomfort to the worker.

When purchasing an electric shovel, you must take into account all of the listed features, as well as pay attention to the technical characteristics of the tool: the lower the power of the electric motor, the more delicate the shovel is. For example, a 1000 W tool can burn out when working with compacted snow, because most models of manual snow blowers are not equipped with overheating protection.

The cost of electric shovels depends on the power, equipment, and manufacturer brand. Thus, there are models on the market at prices ranging from 5 to 10 thousand rubles.

Selection rules

Of course, the main criterion for choosing an electric shovel is its power, however, the ease of use and durability of the tool is also affected by the material from which it is made. On sale you can find electric shovels with a plastic body. They are quite light and easy to use. At the same time, low-quality plastic can be significantly damaged when working in severe frost or when colliding with an obstacle.

An alternative to plastic in the manufacture of an electric shovel can be aluminum or even wood. Aluminum tools are the most reliable, but have a relatively high cost.Wooden shovels with electric drive are a rarity on the market. They are often made by craftsmen in their workshops.

When purchasing an electric shovel, you need to pay attention not only to the material from which the body is made, but also to the material of the auger:

- During operation, a metal auger damages the coating of paths and platforms;

- the plastic screw often breaks;

- an auger made of soft rubber or silicone is the best option for an electric shovel;

- a plastic auger with a rubber lining combines durability and ease of cleaning.

These material features must be taken into account not only when choosing a factory-made electric shovel, but also when making the product yourself. You can learn more about how to make an electric shovel for snow removal.

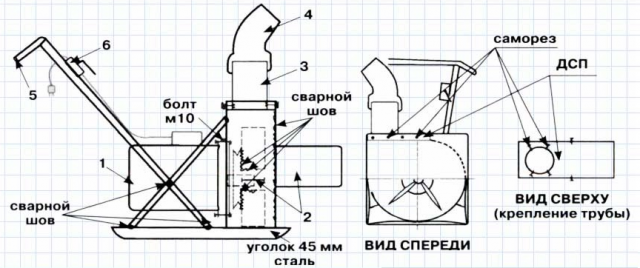

Reliable DIY tool

You can make a high-quality and reliable electric shovel with your own hands. At the same time, a more powerful engine and adapted design will increase productivity and improve the quality of snow removal.

To make an electric shovel you will need:

- Electric motor. You can use a two or three phase motor. The drawings proposed below are designed for a three-phase motor with a power of 2.2 kW.

- Automotive pulley.

- 2-4 steel blades, size 12*15 cm. It is recommended to use steel with a thickness of at least 3 mm.

- Steel sheet for making a shovel body.

- 4 M10 bolts.

- Sewer pipe and angle of the same diameter under 1200.

- Steel corners, 35 cm long, for making runners.

- Pipe with a diameter of 20 mm for making a control handle.

- Batch switch.

You can make an electric shovel with your own hands as follows:

- Press a car pulley onto the motor shaft.

- Weld metal blades to the pulley.

- Make a metal casing around the blades. Weld a wedge-shaped grip for snow to it.

- Attach the resulting housing to the motor with bolts.

- Cut a hole on the fan housing. Its diameter should be equal to the diameter of the sewer pipe.

- Cut a hole of the same diameter on a wooden block. Insert a pipe into it, secure it with self-tapping screws and secure the block to the fan housing so that the hole in the fan housing coincides with the location of the pipe.

- Weld skids and a handle for controlling the electric shovel to the body.

- Attach the packet switch to the handle of the tool.

By analogy with the technology proposed above, a gasoline snow blower can be designed. If desired, you can make some modifications to the design, additionally equipping the electric shovel with a headlight, wheels or other elements.

An electric shovel can become an indispensable helper in the household if you choose it correctly and use it carefully. It will cope wonderfully with fresh snow, clean yard paths, platforms and even the roof. At the same time, you need to work with such a tool regularly, because even slightly compacted or melted snow will no longer be subject to the power of an electric shovel. Many models of electric shovels are quite fragile and require a delicate approach to work. The most passable and reliable design can be made independently. We have provided all the necessary information for this in our article.