Content

- 1 Design options

- 2 Selection and preparation of cylinders

- 3 Do-it-yourself rules

- 4 What and how can you smoke in a barbecue from a gas cylinder?

- 5 Conclusion

A do-it-yourself smokehouse-barbecue from a gas cylinder can be made by anyone involved in welding. The design is often made multifunctional, making it possible to cook dishes according to different recipes. There are several options for such smokehouses. To make one of them, you will need a diagram, 2-3 cylinders and the desire to work.

Design options

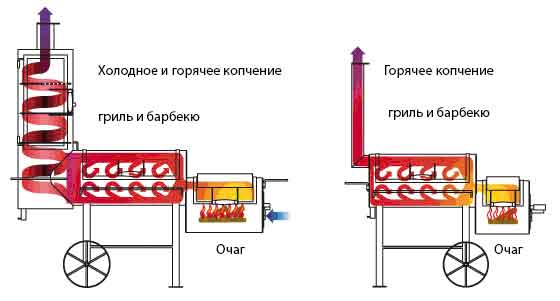

The smokehouse is a closed chamber with suspended products. Smoke from a smoke generator is supplied inside through the channel. This scheme is acceptable for a cold smoked smokehouse. The second design option similarly has a closed chamber. There is no need for a smoke generator to produce smoke here. The camera is installed above the firebox. The fire warms up its bottom, causing the wood chips to smolder.This scheme is used for a hot smoked smokehouse.

Multifunctional smokehouse consists of 3 cylinders

Smokehouses are not limited to differences in the type of smoking. They are often made multifunctional, allowing you to prepare other dishes:

- Brazier. The device is a trough where you can cook shish kebab on skewers. It is made from a horizontally laid cylinder with a cut-out window on the side. You can weld stops onto the grill from the inside and lay a grate on them. Now it is available to be used as a barbecue. However, that's not all. The segment cut from the side shelf of the cylinder is not thrown away, but is secured in the same place with loops. It turns out to be a lid. If you equip the grill with a grate and cover it on top, it turns into a grill.

- Place for a cauldron. The firebox does not have to be used only to produce smoke in the smokehouse. It is also made multifunctional. On a vertically located cylinder, cut off the top plug. A cauldron is immersed in the hole, in which pilaf, fish soup, and kulesh are prepared.

Typically, a multifunctional smokehouse consists of three cylinders: 2 large and one small. A large cylinder is installed vertically. It plays the role of a smokehouse where cold smoking occurs. Behind it, a second large cylinder is laid horizontally. It plays the role of a smokehouse, where hot smoking occurs, and is also used for grilling, barbecuing and grilling. Next in line is the third small cylinder, which is also placed vertically. It plays the role of a firebox and a place for a cauldron. All containers are connected to each other by a smoke channel made of a metal pipe.

Pros and cons of designs

If you want to construct a grill-smokehouse from a gas cylinder with your own hands, you need to think through all the pros and cons of such a design. If there are more positive aspects, you can safely turn your idea into reality.

The positive aspects include:

- Simplicity of design. It is easier to weld a multifunctional smokehouse from ready-made metal containers than to build it from brick.

- Mobility. Despite its impressive weight, the smokehouse is mobile. If you put it on wheels, then in the yard you can roll it from place to place for one person.

- Long service life. The cylinders are made of thick metal. The smokehouse will last at least 10 years, and with good care it will last a lifetime.

- Aesthetics. The smokehouse can not only be welded, but the seams can be carefully cleaned, painted with fire-resistant paint, and decorated with forged elements. The structure will decorate the site, a resting place near the gazebo.

Near the smokehouse you can adapt a tabletop for cutting food

Among the disadvantages is the impossibility of performing work in the absence of a welding machine and welding experience. The downside is the need to carry out complex measures to clean the containers from gas and condensate.

Selection and preparation of cylinders

The ideal use of a gas cylinder is explained by its characteristics. It has a convenient diameter of 300 mm, walls made of thick metal. Essentially, this is a ready-made camera. Large containers are used to assemble smokehouses and barbecues. A small cylinder is used to create a firebox and a place for installing a cauldron.

Condensate is drained from the cylinders and thoroughly washed with water.

In addition to gas, inside the container there is liquid condensate with a very pungent odor. All this must be removed through an open valve. Disposal is carried out away from residential areas and green spaces.

The next step is to unscrew the valve itself. It sits firmly on the thread. You'll have to put in a lot of effort. After unscrewing the valve through the hole, fill the bottle with water and leave it for a day. The liquid with condensate impurities is drained. Now you can cut it with a grinder.

Do-it-yourself rules

Once the containers are prepared, you can begin assembling the smokehouse. First, prepare a diagram, select appropriate materials and tools. You need to remember about safety precautions, because assembling a smokehouse-grill from a gas cylinder with your own hands involves welding work and a sharp grinder.

Safety precautions

Cylinders are cut after they are freed from gas and flammable condensate. Otherwise, an explosion may occur. When working with a grinder, the tool is positioned so that the cutting disc is to the left of the body. Sparks should fly under your feet, and not in the opposite direction.

As the disc rotates, the cut is always done by yourself

The grinder is used not only for cutting, but also for grinding welding seams. The tool is positioned so that the disk is at an angle of 15 O to the treated area.

Selecting a model and drawing

The assembly of the smokehouse begins with design. The choice of schemes here is small.The model of cold and hot smoking is assembled from three cylinders. For a smokehouse using hot smoking technology, you need two containers.

Depending on the chosen scheme, two or three cylinders will be needed to assemble the smokehouse

Preparation of tools and materials

In addition to the cylinders themselves, a pipe and elbows with a diameter of 80-100 mm are prepared for the smokehouse. You need a corner, sheet steel 4-5 mm thick, a tube with a cross-section of 15 mm for the legs. If the smokehouse is supposed to be mobile, prepare the wheels. You will also need handles for the doors and a stainless steel rod for the grates.

The welding machine is the main tool when assembling the smokehouse

The tools you need are a welding machine, a grinder with a set of cutting and grinding wheels. You will also need an electric drill, a hammer, a chisel, and a tape measure.

Procedure

Assembling a barbecue smokehouse from a cylinder with your own hands is carried out in a certain sequence. First, the workpieces are marked and sawed. Then everything is welded. The finale is arrangement and decoration.

Marking and cutting of cylinders

The marking of the containers will depend on what type of smokehouse is selected. First, it is worth considering the simplest version of the design, operating using hot smoking technology, consisting of two cylinders.

Under such a smokehouse, the cylinder is placed horizontally. It will additionally play the role of a grill, barbecue and grill. A large rectangular window is cut out on the entire side shelf. Round holes are cut at the ends for the chimney and the smoke channel from the firebox.

For a large cylinder, a window is cut out along the entire length of the side shelf until the beginning of the joints, where the ends are rounded

A small firebox can be placed horizontally or vertically. In the first case, a rectangular window in the side shelf is cut out in the same way.However, it is impossible to install a cauldron on such a firebox. If there is such a need, the cylinder is placed vertically. Only the top plug is cut off, freeing up space for the cauldron. Two small windows are cut on the side shelf for the ash pan and the fire door. Additionally, one round hole is cut for the smoke channel.

The next option is more difficult. The smokehouse, operating using cold and hot smoking technology, consists of three cylinders. The firebox and grill are made exactly as in the previous version. In the scheme, only the third cylinder is added under the cold smoking chamber. It is located vertically in front of the grill. A window is cut into the container to load products. Place it on the side at the top of the container. The length is about half the cylinder or a little more.

A round window is cut into the top plug for the chimney. The channel for supplying smoke will be located on the side shelf of the cylinder in its lower part - below the loading window. Here they cut a similar round window for the pipe.

Additionally, grates need to be cut into the firebox. They can be made from a thick metal plate by drilling many holes. Smoke channels are made small. A pipe with a diameter of 80-100 mm is cut into lengths from 20 to 50 cm. The length of the chimney is at least 1 m.

Stand

To make it convenient to smoke in a barbecue from gas cylinders, the structure is placed on a stand. Its height is adjusted according to your own height. A stationary version of the stand is considered to be a design with legs. It is welded from tubes. Be sure to install jumpers so that the legs do not move apart.

For mobility of the smokehouse, the stand can be placed on wheels. They are taken from an old stroller, wheelbarrow or other device.

In the stand you can install two wheels in front, and weld a leg from a pipe at the back

A frame from a stroller, wheelbarrow, milking machine or other device is suitable as a ready-made stand. An important condition is the strength and stability of the structure.

Assembly and welding of the structure

Assembling the smokehouse begins by installing the first cylinder on the stand. For stability, control tacks are made by welding to the stand frame. A smoke channel pipe is inserted into the round hole and scalded. A second balloon is placed on its other end with a hole. The joint is scalded.

If the smokehouse has three chambers, perform similar actions. A piece of pipe is inserted into the hole of the second cylinder. The pipe is boiled. A third cylinder is placed on the second end of the pipe with a hole and processed by welding.

When the entire structure is welded, the multifunctional smokehouse is securely welded to the stand

Lids, handles, grilles

The next element is to weld the grate of the smokehouse smoke generator. They are placed inside a small cylinder between the doors of the fireboxes and the blower. The grate bars can be made removable by placing them on welded supports made from corners.

Inside the smoking chamber, stands are welded for the grates on which the products will be placed. They are made in three levels. A tray is placed on the lower stands at the bottom of the cylinder to drain fat. Grates are laid on the second and third tier. They are welded from stainless steel rod.

If necessary, you can make three tiers of grates for food in the smokehouse

Cut segments from the side shelves of the cylinders are used for smokehouse doors, fireboxes and a grill cover. On one side they are secured with ordinary door hinges. On the other side of the window, a limiter is welded so that the sash does not fall inside the cylinder.A handle made of non-heating material is installed on each door.

Preparation for barbecue, barbecue, grill

Holders are welded inside the grill. A barbecue and grill grid is placed on them in the same way. So that you can grill shish kebab on the grill, cuts are made with a grinder at 10 cm increments along the end of the front side for skewers. On the opposite side, where the hinges of the lid are fixed, holes are drilled for skewers, departing 1-2 cm from the end of the side.

Chimney installation

The chimney is welded to the end of the first cylinder, which acts as a smokehouse. If this is a hot-smoked design with a horizontal chamber arrangement, then first the elbow is removed from the hole, and a pipe is welded on top of it.

The chimney pipe is removed from a horizontally located cylinder with an elbow

In a cold smoked smokehouse, the cylinder is located vertically. Here, without an elbow, the pipe is simply welded by inserting it into the hole at the end.

Manufacturing of shelves and fixtures

Shelves provide convenience for working with the smokehouse. They can be made in the form of a table top, placed under the grill on the jumpers of the stand. The shelves are convenient for placing food, wood chips for smoking, and firewood.

A shelf for firewood and wood chips is located at the bottom of the smokehouse stand.

When cooking meat on a barbecue or grill, you have to turn it over. Accessories for this task should always be at hand. You can hang them on hooks welded to the body of the smokehouse.

Finishing

To prevent the smokehouse from looking like a pile of metal, finishing gives it an aesthetic appearance. Jewelry made from forged elements looks best.Handles and shelves can also be carved from wood and given a beautiful shape.

Forged elements are used to decorate the smokehouse stand itself, and if desired, they are welded onto the body of the cylinders

Sanding and painting the structure

Grinding the weld seams themselves is not enough. The cylinders are covered with regular red paint. When the smokehouse starts working, the heating material will begin to turn black, burn, and emit an unpleasant burning smell. All old paint must be removed. The best way is to install a brush attachment with metal bristles on an angle grinder or drill. She will clean the body of the smokehouse until it shines.

If the smokehouse is not painted, the metal will begin to rust over time. For these purposes, they use a special thermal paint that does not fade.

What and how can you smoke in a barbecue from a gas cylinder?

The design is considered multifunctional and suitable for different dishes. Pilaf, fish soup, and other first courses are prepared in a cauldron. The grill is in demand for grilling barbecue. Steaks, sausages, and vegetables are cooked on the grill and barbecue.

In a smokehouse, a fish is hung by its tail

All types of meat, fish, semi-finished products, and lard are smoked in the smokehouse. The product is loaded raw, salted or pre-slightly boiled. In the smokehouse, cheese, vegetables, fruits, and mushrooms are smoked using cold smoking technology.

To obtain different flavors of the product, wood chips from certain types of wood are selected for smoking.

Conclusion

A smokehouse-barbecue from a gas cylinder can be made and installed under a canopy with your own hands. This is the best place, as it is protected from precipitation by the roof. The product can be prepared even in bad weather.