Content

Many manufacturers make smoked products using “liquid” smoke and other chemicals that do not truly smoke the meat, but only give it a specific smell and taste. This method has little in common with traditional smoking. To prepare delicacies, we use high-quality raw materials and time-tested technologies.

Products prepared by cold smoking are stored for a very long time and retain a unique smoky taste. You can make such delicacies at home, the only thing you need is a smoker. Such an installation is not cheap, you can save a lot by assembling smoke generator with your own hands.

Purpose of the device

A smoke generator is a device in which fish and meat are saturated with smoke for a long time. Most often, a smoke generator for cold smoking is driven by gas. A stream of fuel is supplied to the smoking cavities under high pressure.

Smoking devices differ in the size of the smokehouse, the duration of operation and the volume of smoke produced. If you plan to produce delicacies for yourself and your family, a small installation will be enough. You can put up to five kilograms of meat or fish into the smoke generator at a time.

DIY smoke generator

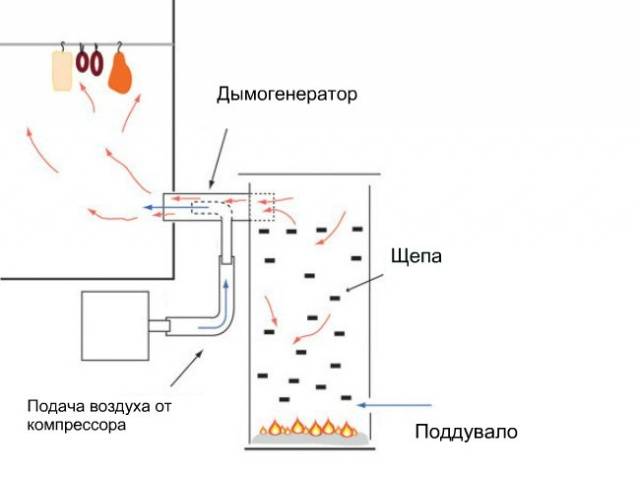

In order to make a smoke generator for cold smoking with your own hands, you can look at the ready-made drawings.

They will help during work. The smoke generator circuit will serve as an assistant throughout all stages of construction.

All of them have a cylindrical metal body. Solid fuel is placed in it, where it smolders. It is thanks to the slow burning of the chips that abundant smoke is formed in the housing. Various wood inclusions are used as fuel for the smoke generator: apple, pear and other species.

In order for the wood chips to burn slowly, they must be laid in a special way. To ignite raw materials, a hole is installed in the lower part of the housing.

Smoke is generated in the firebox of the smoke generator. The process can occur in two different ways:

- A flow of air slowly enters the smoke generator housing, causing the fuel to smolder. The flap on the window of the structure allows you to regulate the level of oxygen supply.

- The design contains two chambers. A place for fuel is installed under the smoking chamber, and fuel is placed on a metal tray from below. Thanks to this arrangement, smoke enters the upper chamber of the housing.

In the smoking chamber, the meat is placed at different levels. When filled with smoke, the tank and the food in it become saturated with aroma. It is important to carefully monitor this process. Gas and electric fireboxes will help make smoking easier.

Generator cooling methods

The cold smoking process, as the name suggests, requires cold smoke.However, initially the combustion process produces warm smoke, so it is cooled. You can build a smoke generator for a cold smoked smokehouse with your own hands quite quickly. For this, a drawing and instructions are drawn up in advance.

Water cooling

To make a water-cooled smoke generator with your own hands, you need two tanks. In this case, one of them is located inside the second. Water moves in the outer vessel; to reduce consumption, the supply rate is reduced.

An internal water vessel cools the smoke. Touching its cold walls, the flow cools down. For high-quality, uniform smoke, regular water pressure is required.

Air cooling

The cooling process itself is carried out due to the heat exchange of the smoke generator. The advantage of such an installation is its low cost and simple device. The smoke generator coil can have any length and diameter.

To save money, the installation coil is located around the firebox. Good circulation of air masses is needed, otherwise the hot body will not allow the smoke to cool.

Smoke generator assembly

To construct a smoke generator for cold smoking with your own hands, you will need drawings.

For construction you will need to select materials:

- profile steel pipe for supplying smoke with a diameter of 2-5 cm;

- square or round pipes;

- corrugation or metal sleeve for the outlet pipe;

- tee adapters;

- compressors;

- wiring.

For assembly you need welding equipment and a grinder. When installing a smoke generator, you need to consider the following nuances:

- If the bottom of the structure is removed, doors are not made on the sides of the body;

- The cover on the top of the case is not equipped with ventilation and other openings; special barrier structures are mounted on it;

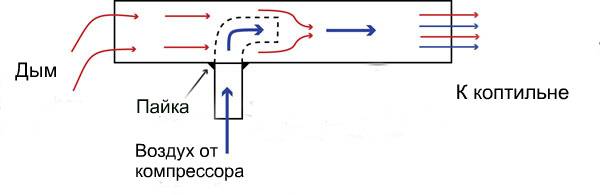

- A smoke exhaust is installed at the top of the installation by welding the fitting perpendicular to the wall.

- Cut the threads of the smoke generator fittings.

- As soon as the chimney part is installed, the tee element is connected.

- The compressor line is attached to the nozzle.

- The fan is replaced with a computer cooler.

The tee must be mounted on the cover. It is important that the integrity of the walls is not compromised.

The design can be combined. In this case, some of the parts are purchased in the store, some are made from scrap materials. This installation can be stored in a basement or garage. The volume of the container directly affects the amount of products that can be smoked in it.

The device works like this:

- The device is mounted on a heat-resistant base. This is usually a concrete slab.

- The design heats up quite quickly.

- About 0.8 kg of sawdust is placed in the container.

- The lid of the structure closes.

- A compressor pipe is connected to it, and the chimney is connected to the smoking chamber.

- The fuel is ignited through a side hole.

- Turn on the fan.

Using a thermometer, you can determine the temperature in the smoke generator. During the construction of such a structure, materials that are at hand are used. To make your own smokehouse, you can use saucepans and similar cylindrical containers. The chimney can be made from any pipe that is at hand. This installation can be operated without a fan. The thrust will be weaker.

If you have a lot of available materials, as well as experience in creating similar structures, building a smoke generator for cold smoking will not be difficult.

Features of the smoke generator assembly

To ensure that air is constantly supplied to the device, a pump is installed. If you don't have one, an aquarium compressor can do the job. A home fan can also be used for this purpose. You just need to connect the air source to the plastic bottle. Now the element can be considered ready. The smoke generator device is quite simple, however, it requires special attention.

The main difference between the smoking device is that it can use almost any type of wood for fuel. You will have to discard pine and spruce, since they contain a lot of resins that interrupt the smell of the dish. It doesn't matter how large the chips are. However, if fairly fine sawdust is used as fuel for the smoke generator, the design should be supplemented - install a spring through which smoke will pass through the layer of sawdust.

The temperature of the smoke in the smoke generator is very important for the final result. The aroma and appearance of the products depends on this indicator. Many models of smoke generators allow you to adjust the temperature at your discretion. You can reduce or increase the length of the pipe. For the main smokehouse, you can choose various products. Installing and connecting a compressor for a smoke generator with your own hands is a rather complex process that should be entrusted to a specialist. You can figure out how to make a smoke generator in the process of preparing the materials.

Often a gas cylinder is used for the smokehouse of a smoke generator. A metal barrel will also come in handy. For cold smoking, you can adapt a non-working refrigerator.This is due to the fact that such structures close quite tightly. They are perfectly insulated and can maintain a certain temperature inside themselves.

As you can see, building a cold smoked smoke generator with your own hands is not as difficult as it might seem. All you need is free time and your own imagination. Such structures are made practically from scrap materials.

To understand the process of creating a smoke generator, it is better to watch a video that presents a demo generator that has already been made.