Content

An ax is used not only for chopping wood. It serves as an indispensable carpenter's tool. People go hiking and hunting with a hatchet, and ancestors, in general, used it instead of a weapon. There are many varieties of this tool, differing in size, as well as the shape of the chopping blade and handle. Now we will look at how to make an ax for household needs and a case for storing it.

Making axes for different purposes

It’s easier to buy a carpenter’s tool or a wood splitter in a store. They are sold already mounted on the handle. If desired, you can make a chopping tool yourself. To do this, you just need to purchase a blade.

Making a battle ax

The military weapon is also called an ax. This model is characterized by a narrow spine and a low blade. The main difference of the ax is its long handle - at least 50 cm, as well as its light weight - about 800 g. There are many types of military weapons: with a double-sided blade, a spike on the butt, etc.

A simple battle ax can be easily made from a carpenter's axe. To do this, use a grinder to cut off the upper part of the blade so that it turns out straight. A hook is cut out on the lower part, and the blade is given a rounded shape.The metal workpiece is hardened in fire, after which it is polished and sharpened. The handle is made of birch with a cut at the end. After placing the head on the ax handle, a wedge is driven into the cut.

Making a wooden ax

A chopping tool can even be made from wood. It cannot be compared with its metal counterpart, but it is ideal for cutting thin brushwood on a hike. Hardwoods, such as oak, are used to make an ax. Moreover, the workpiece must be dry, without cracks and knots. The head with the ax can be made in one piece or in two parts. This is what you like. To make a wooden ax, a template is applied to the workpiece, after which you will need to apply carpentry skills. The blade of the finished weapon is sharpened and then lightly burned over a fire.

Making a hunting ax

In a hunting chopping weapon, the correct balance of the handle is valued, allowing you to accurately strike. Experienced hunters like to use solid hatchets, entirely forged from metal. They are convenient for chopping animal carcasses. At home, it is easier to make a hunting weapon with a wooden handle. The head is taken from a carpenter's ax and a thin wedge-shaped blade is sharpened with an emery wheel with a fine abrasive. It should be slightly rounded, but not semicircular.

The handle is cut from a birch blank. Rowan is a good choice. A groove for the wedge is sawed at the end. The size and weight of the handle depends on who the person will hunt:

- for small game, a light handle weighing up to 1 kg and a maximum length of 60 cm is sufficient;

- for a large animal, the handle is lengthened to at least 65 cm, while its weight increases to 1.4 kg.

The wedge for spacer the edge of the handle must be made of wood. Over time, the iron will begin to rust and fall out of the groove.

Making a taiga ax

Now we will look at how to make an ax for cutting wood or processing logs. Such a tool is called taiga, and it weighs about 1.4 kg. The tool differs from a regular ax in the shape of its axe. The handle is made with an elongated beard, which prevents it from breaking when delivering strong blows. The blade is sharpened so that its back edge is almost 2 times narrower than the front. The head of a taiga ax should have a smaller angle of inclination to the handle than that of a carpenter's analogue.

The video shows how to make an ax:

Making an ax

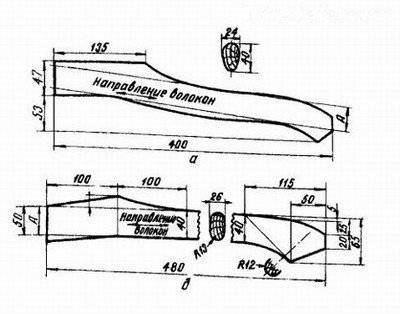

Now it’s time to consider how to make an ax handle from a wooden blank. For a light tool, you need an ax handle weighing 0.8–1 kg and a length of 40–60 cm. For a heavy tool, the weight of the handle reaches 1.4 kg, and its length is 55–65 cm.

However, the length of the handle must be selected so that the self-made tool is comfortable to use. Therefore, it is also important to take into account a person’s height, as well as his physique. For the ax handle, blanks from hard deciduous wood are used: birch, acacia, ash, etc.

To make an ax handle, a template is applied to the dried workpiece. Next, woodworking tools are used: jigsaw, knife, chisel, etc. Finishing is done with sandpaper. The finished ax handle should fit tightly into the eye of the head.If the handle fits in easily, it means it’s defective. Wedging will not help here, and you will have to do everything again.

Fitting the head and sharpening the blade

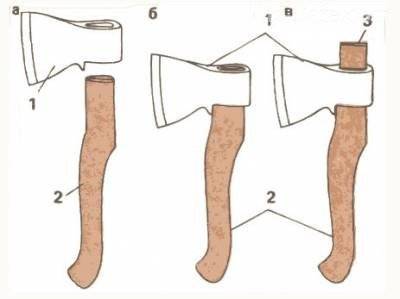

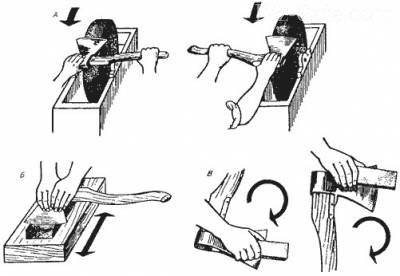

When the handle is ready, make a cut in the upper part with a hacksaw. Its depth is equal to half the width of the head eye. Next, there is the process of attaching the metal part to the ax handle. The process order is shown in the photo:

- the head is stuffed onto a vertically mounted handle, striking the bottom of the ax against a wooden surface;

- When the edge of the ax is level with the upper part of the eye, a wooden wedge is driven in, and its remaining protruding part is cut off with a hacksaw.

When the ax is completely ready, lubricate the handle with any oil. Let it soak in a little, and then wipe thoroughly with a rag.

The blade of a construction tool is sharpened at an angle of 20–30O, and the carpenter’s tool is at an angle of 35O. It is better to do this on an electric sharpener. First, a wheel with a coarse abrasive is used for rough sharpening, then the blade is ground with a fine-grained stone.

Making a case for storing and transporting an ax

For safety reasons during transportation and storage of the ax, you need to make a case. Let's consider three simplest options:

- It’s easier to make a ready-made ax case from a leather briefcase or an old bag. To do this, you need to draw the contours of the head on the material with a margin. Next, using a shoe hook and an awl, sew along the markings. Now the bag is ready. So that the ax case can be hung on a belt, two loops are sewn on the back side. Alternatively, it is easier to cut two holes and thread the belt through them.

- If you have pieces of thick leather lying around, you can use it to make an excellent case for an axe.To do this, you need to draw a head on the material with a pencil, and then cut out two identical fragments. Next, they will have to be sewn. To prevent the case from falling off the head, you can use buttons to secure two strips of leather. They should cover the butt of the ax in the stowed position.

- Having a hair dryer and a PVC drain on hand, you can make a good case for an ax. The plastic blank is heated well, after which they begin to bend it from the side of the butt. When the product takes the desired shape, cut off the excess pieces of plastic with scissors.

Any ax cover considered will protect a person from injury during transportation.

That's all the subtleties of making an ax at home. During the process, it is important to remember safety precautions so as not to accidentally injure yourself on the sharp blade.