Content

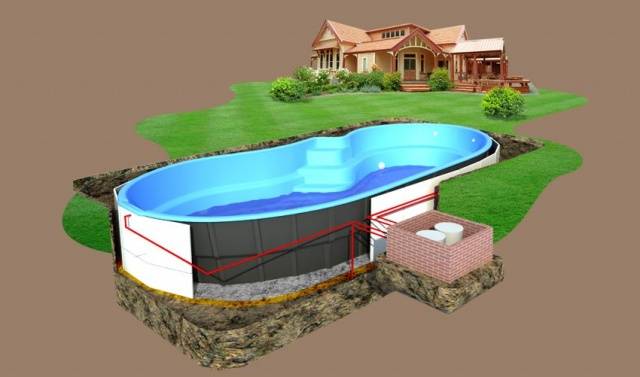

Collapsible type bathtubs in the country are good because of their mobility. However, the bowl standing in the middle of the yard, like an old trough, spoils the whole view. Another thing is a pool for a summer residence, dug into the ground. The stationary font fits harmoniously into the landscape design, creating an excellent place to relax.

Types of in-ground fonts

A stationary pool in the ground is constantly outdoors in all weather conditions. The bowl is affected by severe frost, soil pressure, and the upper layers of groundwater. In order for the font to serve for many years, special requirements are placed on the material and installation technology.

Polypropylene bathtubs

One of the most popular materials for in-ground pools is polypropylene. Elastic properties allow you to give the bowl any shape. The material does not decompose in the ground, is environmentally friendly, is characterized by low weight and high strength. A polypropylene pool can be temporarily installed on a flat area, but usually it is dug in and a concrete base is poured under the bottom.

The advantage of polypropylene hot tubs is as follows:

- Flexible polypropylene sheets allow you to create a bowl of any shape.

- The font will fit into the landscape design and decorate the site. If desired, the bowl can be camouflaged, hidden away from view.

- Polypropylene walls do not require additional sealing. After installation, the bowl is ready for use.

- Polypropylene has anti-slip properties. A man stands steadily in the water. The smooth surface can be easily cleaned with a brush or vacuum cleaner without the use of chemicals.

- Polypropylene retains heat well, and fungus does not grow on the surface.

- In-ground polypropylene pools are characterized by a long service life and do not fade under the sun.

Polypropylene in-ground pools have disadvantages, but they are more often noticed by fastidious users:

- Over time, scratches appear on the surface of the bowl. Often this happens due to the fault of the owners due to negligence, as well as violation of the rules for caring for the pool.

- Installation of a polypropylene hot tub involves soldering with an extruder. If the technology is violated, noticeable joints of the sheets will remain on the bowl.

- The monochromatic color is not to the liking of lovers of mosaics or border designs.

- Owners of concrete pools with an elite finish believe that polypropylene bowls have a cheap look.

Despite the small list of disadvantages, polypropylene pools are easy to install and are the best solution for a summer residence.

Concrete fonts

Concrete pools for summer cottages, dug into the ground, are considered the most reliable. Various finishing options with decorative materials allow you to create a real architectural work of art.The only problem is that the process is labor-intensive, and if the installation technology is violated, the concrete bowl can crack.

Concrete pools have the following undeniable advantages:

- Concrete is resistant to low temperatures. In winter, the pool can be used as an excellent ice skating rink.

- A reinforced concrete bowl will last at least 20 years. In case of mechanical damage, the walls can be repaired.

- The use of decorative stone and other finishing materials can give the pool a luxurious look.

- When pouring a concrete bowl, you can create depth differences, steps and other elements for comfortable swimming.

The following points stand out among the disadvantages:

- Building a concrete pool will be expensive. In addition to the cost of materials, you will additionally have to pay hired workers. It is impossible to pour tens of cubic meters of concrete alone.

- Reinforced concrete construction requires strict adherence to installation technology. An improperly equipped cushion will lead to subsidence of the bottom. Poor quality concrete or weak reinforcing frame will cause the font to crack.

- Concrete pools take up a large area and are not suitable for small cottages.

Having decided to build a concrete structure, it is better to turn to specialists for help.

Bowls made of composite materials

An in-ground composite pool meets all modern requirements. When making a bowl, 6 to 9 layers of material are used. You can order a hot tub only at the factory, and the choice of shapes and dimensions is limited to standard offers. The cost of a composite pool together with installation work is equal to that of reinforced concrete swimming pools.

The advantages include:

- A specialized team performs installation work in a short time. It takes a maximum of a week to arrange the pit and install the bowl.

- An in-ground font made of composite materials is resistant to mechanical damage, as well as the effects of aggressive chemicals.

- The bowl has a perfectly smooth surface without seams.

Any material has disadvantages, and composite is no exception:

- A composite pool is a single bowl of enormous size. To deliver the hot tub to the site, you will need specialized equipment.

- The cost of a composite bathtub is beyond the reach of the average summer resident.

- The consumer does not have the opportunity to purchase an exclusive bowl. The manufacturer offers only standard options.

- Self-installation is not possible. A team with specialized equipment is hired for the work.

A pool made of composite materials is very expensive. However, such a dug-in font is not installed for one year.

Self-installation of a polypropylene hot tub

If you want to install an in-ground pool yourself, it is better to choose a polypropylene swimming pool.

Construction of the pit

An in-ground pool will require a pit. The dimensions depend on the dimensions of the bowl, plus add 1 m in width on each side and 0.5 m in depth. Large gaps are needed for ease of installation, connecting communications and pouring the concrete base.

In a finished pit, it is important to properly arrange the bottom. The soil is leveled and thoroughly compacted. A concrete base is built within the provided depth of 0.5 m.First, sand and crushed stone are poured into the bottom in layers. A reinforcing mesh is laid on top and concrete mortar is poured. Further work is carried out at least two weeks later.

Bowl installation

There are two options for installing a polypropylene pool: the bowl can be ordered from production or soldered independently from sheets. In the second case, you will need equipment for soldering, as well as several training sessions on pieces of polypropylene to gain the skill.

The installation of the pool begins with the arrangement of the bottom. The hardened concrete slab is covered with geotextiles. Expanded polystyrene sheets are used as insulation.

The finished bowl is placed on the prepared base. If you decide to make your own pool, then first solder the polypropylene sheets of the bottom of the pool. The seams are welded twice: inside and outside. After making the bottom from polypropylene sheets, the sides are soldered. For strength, the finished structure is equipped with stiffeners.

Connecting communications

Full functioning of an in-ground pool is impossible without connecting communications. After soldering all the polypropylene sheets, holes are cut out in the finished bowl for the drain and water supply pipes.

The entire pipeline is protected with thermal insulation and connected to the bowl through the bottom and supply nozzle. A filter with a pump and a skimmer are inserted into the system. Additionally, you can install a device for heating water. After installation, a little water is poured into the pool, the bowl is checked for leaks and the functionality of the equipment.

Concreting the bowl

After successful testing, they begin concreting the bowl from the outside. The process is carried out simultaneously with filling the pool with water. It is important to equalize the difference in pressure from the inside and outside to avoid deformation of the walls.

Formwork is installed around the bowl and a reinforced frame is constructed. The sides are covered with polystyrene foam. The slabs will act as insulation and prevent damage to polypropylene sheets by concrete. Concreting is done in layers. 30 cm of water is taken into the pool and a layer of concrete of a similar thickness is poured inside the formwork. After the solution hardens, the cycle is repeated until they reach the top.

After removing the formwork, there will be a gap between the concrete walls and the pit. The voids are filled with soil or a dry mixture of sand and cement. Finally, decorative arrangement of the area around the dug-in pool is carried out.

The video shows an example of installing a fiberglass pool:

Conclusion

Before you decide to install a swimming pool, you need to carefully calculate the expected costs. This will help you choose the right type of bowl and complete the job you started.