Content

Building a swimming pool is expensive. The price of ready-made bowls is exorbitant, and you will also have to pay a lot for delivery and installation. If your hands grow from the right place, you can assemble a polypropylene pool yourself. You just need to buy sheets of elastic material, find equipment for soldering and assemble a bowl of the desired size yourself.

Reality or just a dream

Most owners of private houses immediately reject the idea of installing a swimming pool themselves. If the family budget does not allow it, then you can only dream about a font. However, you should not limit yourself in comfort. Installing a polypropylene pool with your own hands is no more difficult than building a utility block.

Purchasing polypropylene sheets for a bowl will cost much less than purchasing and installing a finished font. However, there will be a problem with finding soldering equipment. It is not profitable to buy because of the high cost, and you will only need the soldering iron once. It is ideal to find equipment to rent. Another problem is the lack of polypropylene welding skills. You can learn to solder on a piece of sheet metal. Some material will have to be ruined, but the costs will be small.

Properties of polypropylene

Polypropylene is easy to use and is in demand by builders when constructing hydraulic structures. The advantage of the material for making a polypropylene pool is as follows:

- The dense structure of polypropylene does not allow moisture and gas to pass through, and retains heat. The sealed material will prevent groundwater from penetrating into the bowl. Due to low thermal conductivity, the cost of heating the pool is reduced.

- Polypropylene is elastic. The sheets bend well, which allows you to create complex bowl shapes. A big plus is the attractive but non-slip surface. A person holds steady in a polypropylene pool without fear of slipping on the steps.

- The sheets do not lose color during the entire period of use. The bowl remains attractive even after exposure to chemicals.

If the installation technology is followed, a polypropylene pool will last at least 20 years. Construction work will last about a month, but will be cheaper compared to buying a solid bowl.

Location of the font

There are only two main places on the site for a polypropylene pool: in the yard or inside the house. In the second case, you will need a specialized room protected from dampness. Due to the large amount of water in the pool, a high level of humidity is constantly maintained, which negatively affects the structural elements of the house.

If the polypropylene pool bowl is installed without recess, high ceilings and additional space will be required. Around the font you will have to build a frame for the sides, install stairs and other structures.

It makes more sense to deepen the polypropylene bowl so that the pool is at floor level. The problem with high ceilings disappears, but the question arises regarding the integrity of the building. Will excavating the soil under the bowl harm the foundation and the entire house?

The best place for a pool is an open area. The polypropylene bowl is not afraid of frost and heat. If you want to protect your resting place or use it year-round, a frame covered with polycarbonate or other lightweight material is erected over the font.

Choosing a place for a bowl in the yard

When choosing a location for a polypropylene pool in an open area, a number of factors are taken into account:

- Location of tall trees. A polypropylene bowl should not be dug in close even to young plantings. The root system of trees grows, reaches for moisture and over time will damage the waterproofing of the font. The second problem will be clogging of the water in the pool with leaves, falling branches and fruits.

- Soil composition. It is better to dig a polypropylene bowl into clay soil. In case of waterproofing failure, clay will prevent rapid leakage of water from the pool.

- Relief of the site. A polypropylene pool is not placed in lowlands, where there is a risk of flooding with rainwater flowing down from the hills along with dirt. If the site has a slope, then it is better to choose its high part.

One important factor is the frequent direction of the wind. In the direction where the air flows are directed, an overflow pipe is placed on the polypropylene bowl. The wind will drive the debris into one place, and it will be removed from the pool through the pipe along with excess water.

Step-by-step guide to constructing a polypropylene hot tub

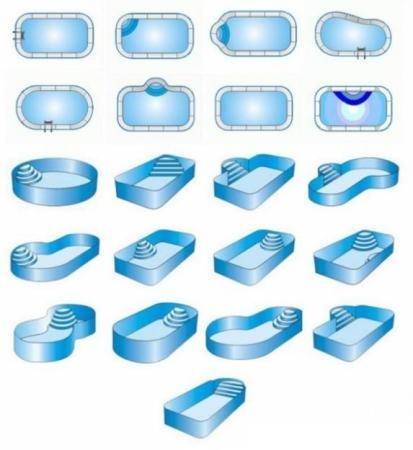

Installation of a polypropylene pool begins with preparing the pit.At this time, you need to firmly decide on the size and shape of the bowl. The instructions for constructing a polypropylene font consist of the following steps:

- The construction of the pit begins with marking the area for the font. The contour is marked with stakes with a stretched cord. The pit is shaped like a future polypropylene bowl, but the width and length are made 1 m larger. The depth is increased by 50 cm. The reserve is needed for pouring concrete and connecting equipment for a polypropylene pool. It is better to excavate the earth using an excavator. If the site does not allow equipment to freely enter, you will have to dig manually.

- When the foundation pit is ready, beacons are made from wooden stakes. They are driven into the ground, indicating the upper location of the contours of the polypropylene bowl. The bottom of the pit is leveled and compacted. If the soil is sandy, it is advisable to add a layer of clay and compact it again. The bottom of the pit is covered with geotextiles. A layer of crushed stone 30 cm thick is poured on top.

- The bottom of the pit covered with crushed stone is leveled. You can check the differences with a long rule or a stretched cord. To create a reliable bottom, a reinforcing frame is made. The grate should not lie tightly on the crushed stone. Pieces of brick will help provide clearance. The halves are laid out along the entire bottom of the pit at a distance of 20 cm from each other. The reinforcing frame is made of reinforcement. Rods 10 mm thick are laid out on bricks in the form of a grid to form square cells. The reinforcement is not welded together, but connected with knitting wire. A hook is used to tie the reinforcement with wire. The device speeds up and simplifies the process.

- You can get a strong monolithic base for a polypropylene pool only by pouring the solution at a time.Large volumes are prepared in concrete mixers. The solution is supplied through homemade gutters made of tin or boards. It’s easier and not much more expensive to buy a ready-made solution mixed in a construction mixer.

- The solution is poured evenly over the entire area of the bottom of the pit, where the reinforcing frame is laid. Layer thickness – minimum 20 cm. Work is carried out in dry, cloudy weather with air temperatures above +5OC. In the cold season, concreting is not done, as there is a risk of cracking of the reinforced concrete slab. If pouring is carried out in hot weather, the concrete base is covered with film. Polyethylene will prevent the rapid evaporation of moisture from the solution. The length and width of the concrete base are 50 cm larger than the dimensions of the polypropylene bowl.

- The hardening time of the concrete depends on weather conditions, but further work begins no earlier than two weeks later. The strengthened and dried reinforced concrete slab for the font is covered with sheets of thermal insulation. Expanded polystyrene is usually used.

- The next stage is the most important. The time has come to start making a polypropylene bowl. Soldering of sheets is carried out using a heat gun - an extruder. The quality and tightness of a polypropylene pool depends on neat seams. If you have not done welding before, practice on pieces of polypropylene. It is cheaper to ruin one sheet of polypropylene to gain skills than to patch a defective bowl.

- The extruder comes with nozzles of different shapes. They are designed for soldering seams of varying complexity.

- Soldering of polypropylene with an extruder occurs due to the supply of high temperature air. At the same time, a polypropylene soldering rod is inserted into the gun.Hot air heats the edges of the joining pieces of polypropylene. At the same time, the rod melts. Hot polypropylene solders sheet fragments, forming a sealed smooth seam.

- Soldering a polypropylene bowl begins with making the bottom. The sheets are cut into fragments of the desired shape, laid out on a flat area and the outer joints of the bottom of the font are soldered. On the reverse side, the joints are also soldered so that the polypropylene sheets do not rupture. To create a strong and thin seam, the edges of the welded polypropylene fragments are cleaned at an angle of 45O.

- The finished soldered bottom of the polypropylene hot tub is placed on a concrete slab, where polystyrene foam has already been laid out. Further work consists of installing the sides of the font. Sheets of polypropylene are soldered to the bottom of the bowl, welding the joints from the inside and outside.

- The sides of the polypropylene hot tub are soft. While welding the sheets, temporary supports are installed to help maintain the shape of the bowl. Polypropylene steps and other specified elements of the pool are welded simultaneously with the sides.

- When the polypropylene hot tub is ready, stiffening ribs are installed around the perimeter of the sides. The elements are made from polypropylene strips. The ribs are welded vertically to the sides of the font, maintaining a distance of 50–70 cm.

- After soldering the bowl of polypropylene sheets, the next important point comes - connecting communications and equipment. Holes are drilled into the font, where drain and fill pipes are connected through nozzles. Communications are connected to the pool pumping equipment and the filter is connected. An electrical cable is laid to the polypropylene font.If lighting is provided, it is also equipped at this stage.

- A little water is taken into the polypropylene pool to test the equipment. If the result is positive, the cup is prepared for strengthening. The procedure involves pouring concrete layer by layer into the gap between the sides of the font and the walls of the pit. The thickness of the concrete structure is at least 40 cm. If the gap remains about 1 m, then formwork is installed along the perimeter of the sides of the polypropylene bowl.

- For strength, the concrete structure is reinforced. The frame is made of rods, according to the principle of reinforcing the bottom of a pit. Only the grille is installed vertically along the perimeter of the sides of the font. Filling the solution is carried out simultaneously with filling the bowl with water. This will equalize the pressure and avoid bending of the polypropylene walls. Each subsequent layer is poured after two days. The procedure is repeated until the very top of the sides of the font.

- When the concrete structure hardens, the formwork is removed. The gap between the walls is filled with earth and thoroughly compacted. The aesthetics of a polypropylene bathtub is provided by butyl rubber or PVC film. The material adheres well and is resistant to temperature changes. The film is spread overlapping along the bottom and sides of the font. Gluing to polypropylene is carried out by cold welding.

The final stage of the work is the cultivation of the area around the polypropylene pool. The ground is covered with paving slabs, wooden platforms are installed, and sheds are erected.

The video shows the process of constructing a polypropylene pool:

The finished polypropylene bowl is a huge structure. To avoid problems with moving the font, soldering of polypropylene sheets is carried out directly at the installation site of the pool.