Content

- 1 Features of composite pools

- 2 What is the difference between a composite pool and a polypropylene pool?

- 3 Pros and cons of composite pools

- 4 Types of pools made of composite materials

- 5 Rating of the best composite pools

- 6 Do-it-yourself installation of a composite pool

- 7 Is grounding required for a composite pool?

- 8 Operation and maintenance of a composite pool

- 9 Composite pool bowl repair

- 10 Conclusion

- 11 Owner reviews of composite pools

Composite pools are swimming pools made from fiberglass with the addition of special components. One of the distinctive features of structures made of composite materials is the possibility of their use not only as a seasonal structure, but also for year-round use with covering for the winter period.

Features of composite pools

Composite compounds include polymer-type products reinforced with ultra-strong fibers of synthetic material. The strength provided by such substances makes it possible to create an alloy that can withstand fluid pressure even in composite structures with large dimensions.

This influences the fact that manufacturers indicate a warranty period for products of 15-20 years. However, while guaranteeing excellent strength characteristics of the structure, manufacturers cannot guarantee the preservation of its original appearance. It, just like the elasticity indicators of a building, changes under the influence of ultraviolet radiation, temperatures, and chemical compounds.

This type of alloy, according to experts, allows not only to provide sufficient strength and durability characteristics with careful handling of the product, but also allows manufacturers to experiment with the shape and shades of products. Others argue that there are no more than 5-6 varieties of shapes and tones of composite structures. In their opinion, this is due to the insufficient number of types of alloys of this type and the need to manufacture an expensive matrix to introduce a new form, which increases the cost of the product for the buyer.

What is the difference between a composite pool and a polypropylene pool?

Before installing a composite pool in their home, summer residents compare this type of pool with polypropylene products that are closest in characteristics and competitors on the market. It is worth taking into account the design features and operating nuances of both types:

- Pools made of polypropylene require mandatory concreting, during which the speed of work is limited by the ability to lay only 20-30 cm of concrete per day.

- Unlike composite pools, polypropylene structures are not made of solid material, but consist of a large number of interconnected sheets.

- Common polypropylene structures are only 5 mm thick.Important! When exposed to temperature changes, damage to the composite pool often occurs, which is almost impossible to repair.

- Structures made of polypropylene have one shade - deep blue, while structures made of composite materials have at least 5-6 color variations.

During production, composite-based compositions can be filled with crumbs of luminous materials, which, in addition to a pleasant glow, will provide the opportunity for additional heating of water.

Experts emphasize that the composite pools shown in the photo below are superior to polypropylene structures in all technical characteristics. However, such equipment has a slightly higher price, which, according to experts and users, is compensated by high reliability and the absence of problems in installation and operation over a long period of time.

Pros and cons of composite pools

The popularity of products made from composite compositions is due to a number of their advantages, which experts include:

- The strength of the material is 10 times higher than that of concrete structures.

- The product is made from a monolith and is subjected to control at all stages of the production cycle; if treated with care, the service life of such a container can reach 50 years.

- Attractive appearance, a large number of shapes and colors, making it possible to use in various interiors.

- Light weight, allowing summer residents to install the equipment on their own.

- Low costs for purchasing, installing and maintaining a pool compared to concrete structures.

- Properties of the composition that allow for less contamination of composite pools and, accordingly, less frequent cleaning.

- Ease of maintenance achieved through the use of components in the material that prevent the appearance and proliferation of microorganisms and mycotic structures.

- The tightness of the pool bowl is made of a composite, achieved by manufacturing it from a single piece.

In addition, if necessary, a composite pool can be dismantled and installed in a new location. However, along with the listed advantages, experts also name a number of disadvantages of such pools, including:

- It is impossible to install a composite pool in places where electrical power, air and underground gas communications are localized.

- There is a possibility that the pool will float up when emptying for cleaning or replacing the liquid.

- The presence of deformations and bending of the pool shape, which in turn causes difficulties (the appearance of cracks) with the installation of lining in the bypass zone located along the perimeter of the composite pool.

- The inability to support the pool bowl when installed on the surface of other structures, which in turn causes a change in the shape and size of the bowl, the deformation of which leads to the destruction of the supporting floor slabs.

- High duration (up to 4-5 weeks) and labor-intensive installation work.

- The need to use special transport for delivery and installation of the finished product, which increases its cost for the buyer.

- Low maintainability and high cost of restoration work.

Despite these disadvantages, composite pools were able to conquer their niche in the market and firmly hold their position thanks to the production of high-quality and durable products.

Types of pools made of composite materials

From the variety of types and sizes, experts distinguish products with oval, rectangular shapes, composite round pools and structures with complex configurations. The bowls of such equipment can be made in various color shades, for example, blue, greenish, emerald brown and others.

Among the well-known solutions, experts cite the use of advanced NOVA colors technology, which makes it possible to achieve a holographic effect through the use of a new color palette. Another option is to use unique color shades with 3D effects Bi-Luminite colors, which help achieve different refractive and reflective indices through layer-by-layer coating.

Rating of the best composite pools

To ensure a long service life of the pool, it is necessary to purchase products offered by manufacturers of composite pools in Russia and the Middle East, using high-quality materials. Such designs provide users with operational safety, high strength, and long service life, which only according to the manufacturer’s warranty is about 20 years. Experts include the following among the most popular manufacturers offering high-quality products to customers:

- “Eri” equipment from the Belarusian company Composit Group, which features a favorable ratio between the cost of products and their quality.

- Composite pools "Toba", manufactured by the Lithuanian company Luxe Pools. In addition to ensuring the required thickness of the product and its insulation, for ease of use, the manufacturer pays increased attention to the ergonomic characteristics of the equipment.

- The “Minipool” model, produced by the Moscow company San Juan, is distinguished by a variety of shapes and colors, the common feature of which is practicality and the absence of insulation. Such products are characterized by high strength and have an average price on the market.

- Equipment “Victoria”, “Grenada”, “Rhodes Elite”, produced by the St. Petersburg company Admiral Pools, is distinguished by low prices and a wide range of products. This company produces pools with a depth of up to 2.5 m and a length of up to 14 m.

- The rating of composite pools also includes products manufactured by Compass Pools (Krasnodar). They offer consumers the equipment “Riverina”, “X-Trainer”, “Brilliant”, the distinctive features of which are an attractive appearance and high ergonomic design.

When choosing from the listed models, consumers give preference to the option that best suits the operating conditions, the intended purpose of the pool and the available material capabilities.

Do-it-yourself installation of a composite pool

Before installing the structure, it is recommended to study the available methods for installing pools made of composite materials. Among them, experts include:

- installation of equipment inside a permanent building;

- lowering into a prepared pit with partial burial;

- installation in a bowl made of composite or concrete located on the surface;

- installation on a surface located inside a closed pavilion;

- installation with making a concrete curb;

- installation on the surface flush with the ground line.

When installing a pool made of composite materials, it is necessary to comply with a number of requirements regarding the safe operation of the structure.

Installation of a composite pool in a country house on the street

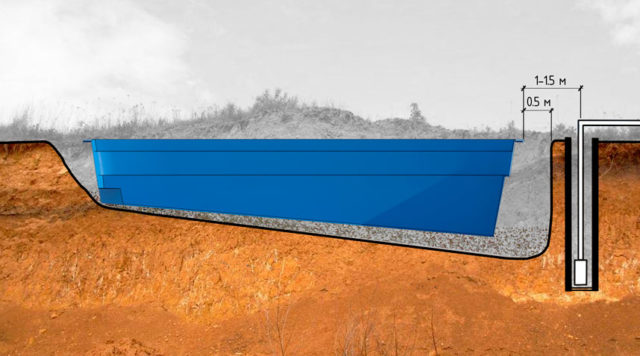

Having decided to install a composite pool on your site yourself, you need to prepare the space for installation. To do this, you need to use an excavator to dig a pit to fit the given dimensions of the structure, with a slight slope, the size of the leg of which should not exceed 50 cm.

The parameters of the pit for arrangement make the depth of the bowl 15-20 cm larger for organizing a cushion of sand and crushed stone. The width of the pit is determined by soil freezing indicators and the degree of heaving in the region; depending on them, it can be increased by 50-150 cm compared to the overall dimensions of the pool for each of its sides.

After this, it is necessary to lay plumbing communications and ensure the organization of drainage of the liquid when replacing it. The sequence of actions when installing a composite pool with your own hands includes performing procedures such as:

- filling the bottom of the pit with crushed stone and sand;

- location of the housing at the installation site using improvised means or special equipment;Important! Pools made of composite materials can be installed around the circumference of the tank on a base made of metal or wood.

- connecting equipment that allows draining liquid during maintenance and filling the bowl;

- filling the distance between the pit wall and the bowl body along the entire perimeter of the structure using crushed stone with simultaneous compaction;

- design in the form of a concrete belt, carried out around the perimeter of a dug-in composite pool for a summer residence.

Installing a composite pool indoors at home

The installation of a composite pool, carried out inside a residential premises, has a number of features, including the use of sections, the size must correspond to the width of the doorway. Installation of the structure can be done using the technology described above during the construction of the building or after its completion.

The pit is made after determining the zero mark, which is tied to the existing areas. The installation of a pool made of composite materials includes the installation of embedded parts with the laying of water pipes in a separate room and the installation of the bowl. After this, the utility room is arranged and commissioning work is carried out.

Is grounding required for a composite pool?

Since fiberglass is not classified as a material with conductor properties, you can do without installing a grounding connection. However, electrical safety rules require that when using pumps, treatment plants and other electrical equipment, ensure the safety of its operation. This requirement is of particular importance given the use of metal parts, for example, handrails and steps of stairs.Thus, based on considerations of ensuring the safe operation of the equipment, grounding is a necessary condition for starting to use the facility.

Operation and maintenance of a composite pool

Maintenance of pools of any type involves regular cleaning of the bottom of the structure using a water vacuum cleaner, replacing filter elements, and cleaning liquids using special means.

The power of the filtration installation used should allow the passage of the entire volume of liquid filling the composite pool within 5-6 hours. Depending on the temperature of the liquid, it must be cleaned 2-3 times during the day. Thus, at temperatures below 24 °C, all liquid must be passed through the filter twice, while at temperatures above 30 °C, all liquid filling the composite pool is cleaned three times.

The operating instructions determine the methods and range of chemicals for water disinfection, measures aimed at preventing the deterioration of water quality in outdoor composite pools for summer cottages.

Along with water purification using chemicals in the pool, mechanical purification using a filter unit is of high importance. Separately, experts highlight the specifics of composite overflow pools, in which filtration occurs when liquid is poured into a special container through the side of the structure.

Composite pool bowl repair

The need for repairs may arise if the structure is installed incorrectly, installation is carried out with the replacement of components, or the recommendations prescribed by the manufacturer when performing work are violated. In addition, on the market you can sometimes find counterfeits of children's composite pools from well-known companies, and therefore it is recommended to purchase a pool from trusted companies or distributors who have a direct connection with the manufacturer.

To prevent costs associated with restoring the functionality of a composite pool, experts recommend:

- Exactly follow the manufacturer's instructions regarding the installation technology of the product.

- Avoid premature draining of liquid from the pool and promptly organize a drainage system when the groundwater level is high.

- When installing a composite pool on washed-out soil or fill soil, before installation, it is necessary to prepare a reinforced concrete slab with a thickness of at least 20 cm for it before installation.

If the bowl is damaged, you must ensure that the pool is quickly emptied, and then file a complaint addressed to the product supplier. It is necessary to describe the characteristics of the damage and attach photographs.

Conclusion

Composite pools are a convenient and durable design. However, for their long-term operation, it is necessary to ensure proper installation and use of the product. Among the important features regarding the specifics of installation, experts call the preparation of the site for the structure. Composite pools have rightfully occupied their niche, combining durability, ease of maintenance and beautiful appearance.

Owner reviews of composite pools