Content

A do-it-yourself hot-smoked brick smokehouse is most often made by smoked meat lovers due to its simple design. However, there are other designs that allow you to smoke products using a different technology. Such smokehouses have a complex structure.

Types of designs

Smokehouses are built in different sizes. They are decorated with finishing, forging, and given an interesting shape. However, this does not apply to differences. You can come up with any design for a brick building. The main type of smokehouse lies in the design and method of smoking the product.

The video shows a do-it-yourself brick smokehouse for cooking fish:

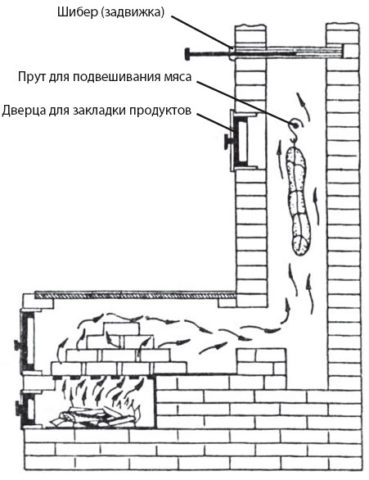

Cold smoked brick smokehouse

The smokehouse has a complex device in which the product is prepared using the cold smoking method. Smoke is supplied to the working chamber from a smoke generator. After traveling a long way through the channels, it cools down. The product is not subjected to heat treatment, but is slowly dried.

In a homemade version, the smoke generator with a supply channel to the chamber is made of brick

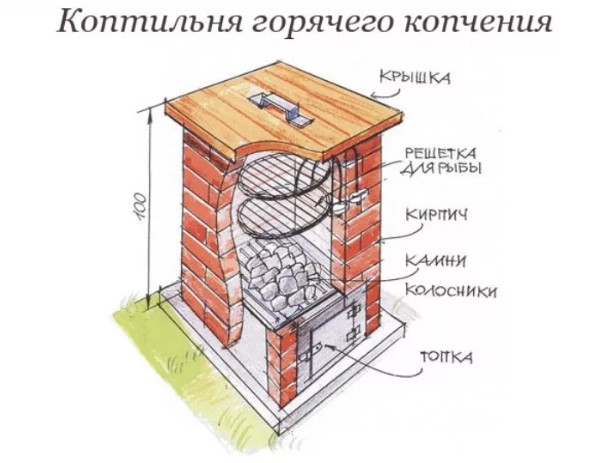

Hot smoked brick smokehouse

The construction is considered simple. There is no need to create channels or make a smoke generator. They build a hot-smoked brick smokehouse with their own hands in the form of a small, elongated house. At the top there is a metal chamber. This is where food is hung. Wood chips are poured into the bottom of the chamber. At the bottom of the smokehouse there is a firebox. Burning wood heats the metal bottom of the chamber, and the sawdust begins to smolder.

The hot smoked smokehouse is small in size

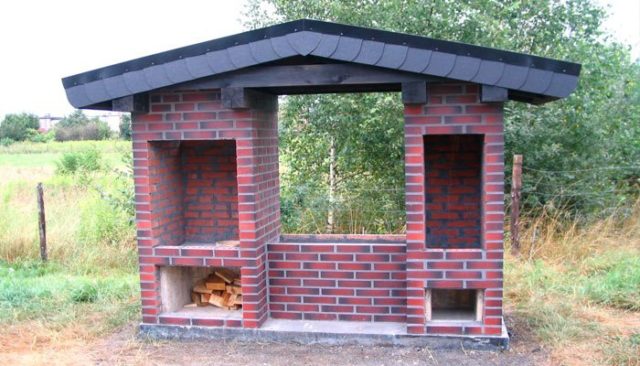

Multifunctional designs

The multifunctional combined smokehouse is considered the most complex in design. Here you can do cold and hot smoking. You will need a smoke generator and a firebox. Often such buildings are equipped with additional work areas: barbecue, space for a cauldron, countertop, dishwasher, shelves, niches. The structure is a whole complex with numerous smoke channels inside. Only an experienced master stove maker can build such a smokehouse.

A multifunctional smokehouse can fully replace a kitchen with all household appliances and a sink.

Drawings of cold and hot smoked brick smokehouses

If you decide to start building a smokehouse, you will need drawings. They give a clear picture of the structure and the location of each row of bricks. It should be noted right away that an inexperienced builder will need drawings of a smokehouse made of hot-smoked or cold-smoked bricks. It is better to entrust the construction of a multifunctional combination stove to a master.

The bottom of the chamber can be made from grates, filling them with stones, or a metal structure in the shape of a tank can be welded

The simplest cold smoker resembles an oven with a long chimney that acts as a chamber for food

How to build a brick smokehouse with your own hands

Before you start building a smokehouse, you need to find a suitable place for it. The next step is preparing the material. It is important to think about protecting a brick building from precipitation. If it is constantly flooded with rain or covered with snow, the structure will not last long. The brick will be saturated with moisture. When igniting wood in the firebox, the water will become steam. The product will not be smoked, but more boiled. After developing the drawing, they begin to build a brick smokehouse with their own hands by preparing the site.

Site selection and preparation

When building any type of smokehouse, you need to understand that it will be a stationary brick structure. The structure cannot be moved to another location. For this reason, the choice of site is approached with all responsibility.

Even a small smokehouse is a stationary building on a foundation that cannot be moved to another location

The operation of a smokehouse involves the release of a large amount of smoke into the atmosphere. For this reason, it is optimal to remove it from your own and neighbors’ residential buildings, as well as green spaces. Choose a location that is not flooded by groundwater or sewage. It is desirable to have stable, dense soil. There will be less costs for arranging the foundation.

The area chosen for the construction of the smokehouse is cleared of vegetation, stones and debris. It is optimal to remove the top layer of soil with grass roots. If the area is not level, it is brought to the appropriate normal state.

Selection of materials and tools

To build a smokehouse out of brick with your own hands, first of all, prepare the building material. Here you need to make the right choice. To make the walls, red solid bricks made of baked clay are used. It is better to line the firebox with another material. Fireclay or refractory bricks are suitable here.

For the walls of the smokehouse, red solid brick is used.

To prepare the solution you will also need different materials. The foundation is poured from concrete. You can lay out the base of the smokehouse using cement mortar with added lime. Brick walls are made using brown clay mortar. Cement cannot be used here. The heat will cause the brickwork to crack. The area near the smokehouse firebox is exposed to high temperatures. Here, laying fireclay bricks is best done on refractory clay. You can buy it at a hardware store. To prepare solutions you will need sand and water.

The tools you need are a standard construction kit. To mix the solution, prepare a shovel, bucket, concrete mixer or large basin.To lay brick, you will need a trowel, a level, a plumb line, and a construction cord. If the walls of the smokehouse are not going to be plastered or decorated with decorative stone, you will need a device for jointing the joints.

Procedure

When the site and all the materials are prepared, it’s time to try to make a brick smokehouse with your own hands according to a pre-designed pattern. Work begins with laying the foundation. It is impossible to do without it, since the smokehouse is heavy. On the ground, the structure may sag and the brickwork may crumble.

Pouring the foundation

The concrete base is a monolithic slab. The foundation should follow the shape of the smokehouse, protruding beyond its boundaries on all sides by about 10 cm. The first thing to do is mark the area. Using a shovel, dig a pit 50 cm deep. The bottom is leveled, covered with a 10 cm thick layer of sand, moistened with water and compacted. Another layer of similar thickness of crushed stone is poured on top.

To create a strong foundation for the smokehouse, it is reinforced. A mesh with a cell size of approximately 15x15 cm is tied from metal rods with knitting wire. The reinforced frame is laid directly on the crushed stone or a black film is first spread for waterproofing.

The formwork must rise above the ground level at least 5 cm

Formwork is installed along the perimeter of the trench from boards. It is optimal when its upper part protrudes 5 cm above ground level. The pit is filled with concrete mortar and crushed stone. The foundation is allowed to stand for at least 1 month. During this time, the concrete is moistened and covered with film. When the monolithic slab hardens, the formwork is removed. The base is covered with two layers of roofing material.Waterproofing will prevent brick walls from drawing moisture from the soil.

Laying

The first row of the order is laid out dry without mortar. Bricks form the overall shape of the structure. It depends on the type of structure:

- When building a cold smoked smokehouse with your own hands, the first row of bricks is immediately used to form a general structure consisting of a chamber, a smoke generator and a chimney duct. The building has an elongated shape. The length of the channel must be at least 4 m.

- For a hot smoked smokehouse, a smoke generator with a long chimney channel is not needed. The first row of bricks follows the shape of the entire structure: square or rectangle.

The next rows of the plinth are laid out on cement mortar. It is prepared with the consistency of thick sour cream. Take 3 parts sand, 1 part cement and 1 part lime.

Simultaneously with the base, an ash chamber is erected - a ash pit.

Construction of the firebox

After the smokehouse base has been erected, further rows of bricks are laid on a clay mortar. It's time to set up the firebox. In a smokehouse made of hot or cold smoked brick, it is always located above the ash chamber. The firebox is laid out from fireclay or refractory bricks on refractory clay. You can go another way. The combustion chamber of the smokehouse is welded from sheet metal and simply embedded in the masonry.

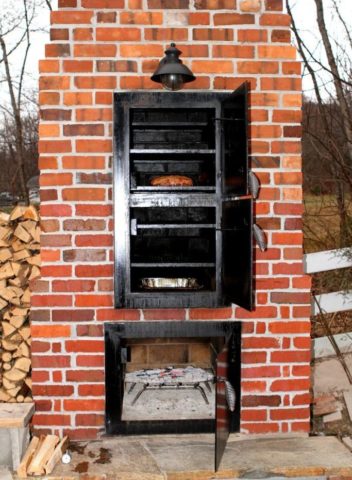

In a hot smoked smokehouse, above the firebox there is a chamber for products

The next element is the smoking chamber. Its design depends on the type of smokehouse, but first determine the size. It all depends on personal wishes. Typically, a chamber measuring 1x1 m and up to 1.5 m high is sufficient for a home smokehouse.

If this is a smokehouse made of hot-smoked bricks, the chamber is welded from metal in the form of a box with a door. The bottom is solid. Wood chips will be loaded here, which will be heated by fire from the firebox. Stops are welded above the bottom and a tray is attached to drain fat from the product. Higher up the chamber, fasteners are fitted for grates or hooks on which smoked products are secured. A window is cut in the upper part of the chamber for the chimney to remove smoke.

If you look at a photo of a cold smoked brick smokehouse, even an inexperienced stove maker will understand that the firebox of the smoke generator is located far from the smoking chamber. There is no need to make a bottom in it, as it will block the flow of smoke from the channel. Here they usually stretch burlap, which acts as a filter that traps soot. The rest of the camera structure is similar. A pallet is hung above the burlap, and grates or hooks are placed above.

Chimney, chimney

In a cold smoked smokehouse, you need to build one more unit from brick - a chimney duct. It connects the smoke generator to the smoking chamber. Its optimal length is 4 m, but sometimes it is shortened to 2 m, which is extremely undesirable. The width and height of the channel is a maximum of 50 cm. It can be laid out of brick and left in this state, or a metal pipe can be built inside.

The channel from the metal pipe embedded in the chimney does not become clogged with mortar spilling out from the seams of the brickwork

The last element of the smokehouse is a chimney with an adjustable damper for smoke removal from the smoking chamber. It is laid out of brick or a metal pipe is installed.A head is arranged on top. It will prevent precipitation from entering the smoking chamber through the pipe.

Testing

After all work is completed, the smokehouse is not touched for at least a week. The brick from the mortar is saturated with moisture. It must dry. After this, the first test is carried out.

The first ignition in the firebox is carried out no earlier than a week after the completion of the smokehouse construction

Testing consists of the following steps:

- If it is a hot smoked smokehouse, wood chips are loaded into the chamber. A fire is lit in the firebox. A smoke generator is lit in a cold smoked smokehouse.

Smoking chips are used from fruit or deciduous non-resinous trees

- A small amount of product is placed inside the chamber, for example, 1 fish or piece of meat.

- The chimney damper is closed. Allow time to fill the chamber with smoke.

- As the consistency of the smoke increases, the temperature rises. It must be maintained according to the recipe of the product being prepared. The temperature is adjusted by opening the damper. For measurements, a pocket for a thermometer is provided in the chamber.

- Testing is carried out over half an hour. During this time, the masonry is checked to ensure that no smoke passes through the seams between the bricks.

The appearance of the product determines the quality of the smokehouse. It should take on a golden color and not be covered in soot.

What and how to smoke in a brick smokehouse

The main products for smoking in a home smokehouse are meat, semi-finished meat products and fish. Depending on the recipe, the product is only salted or boiled first. Smoked poultry carcasses and rabbits are delicious. Sometimes a small pig is buried.

When smoking raw meat, it is first salted

Homemade sausages and lard are sent to the smokehouse. When smoking a whole large fish, it is hung upside down. Fruit lovers prepare prunes and pears in a cold smoked smokehouse.

Photo gallery of DIY brick smokehouses

The smokehouse under its own roof is protected from precipitation

In the smokehouse you can equip a large chamber with entrance doors

A multifunctional smokehouse can be built in a gazebo

The smokehouse in the form of an oven is equipped with a barbecue, countertop and other work areas

In a cold smoked smokehouse, the doors of the working chamber can be made of wood

Fire safety

During smoking, the fire burns inside the firebox. A smokehouse cannot be called a fire hazard, but safety precautions must be observed. A platform made of non-combustible materials is set up near the vent and firebox in case sparks fly out. Do not store flammable objects or liquids nearby.

It is not advisable to locate the smokehouse near greenhouses, gardening, green areas, as trees and cultural plantings may be damaged

Conclusion

A smokehouse made of hot-smoked bricks can be built on a small scale with your own hands. It is better to entrust a more serious structure to a master stove maker or build it yourself, but under his guidance. Mistakes made will lead to the building being destroyed or the product being poorly smoked.