Content

During design and manufacturing, a doghouse has two main requirements: convenience and suitable dimensions. Next, minor issues related to design, roof shape and other details are resolved. This also includes the choice of material. For a yard dog, it is customary to build a kennel from brick, metal or boards. The first two materials are not always convenient for the manufacture of such a structure. Usually the owner builds a wooden structure in the yard dog house, and it is this kind of house that provides maximum comfort to the dog.

What to consider when building a booth

Even before construction begins, one important requirement must be taken into account: a dog house built on your own is not just a kennel, but a real home. The dog will stay in this house all his life. The dog will sleep in the booth or simply hide from bad weather. Housing should be so comfortable that the animal itself will use it without coercion.

When building a kennel from scrap materials in the yard, take into account the important requirements for the design:

- The inside of the kennel should be warm in winter and cool in summer.Such results can be achieved using thermal insulation material.

- Even if the house is made without insulation, they try to avoid the formation of gaps as much as possible. Wind should not blow into the booth and rainwater should not enter.

- A dog kennel is made on a slight elevation. This keeps the bottom always dry, even during heavy rain.

- Young dogs love to frolic and often jump onto the roof of the booth. The strength of the structure must support the weight of the dog.

- Inside and outside the house, it is necessary to completely get rid of protruding nails, screws, chips and other sharp objects that could injure the dog.

- As improvised means, materials without strong chemical odors are used to build a doghouse. Pine boards are considered the best material for building a dog kennel.

- The dog is a yard guard. A properly made hole will help the dog quickly jump out and into the kennel, as well as observe everything that is happening around without getting out of the kennel.

A built simple house for a dog must meet all these requirements, but at the same time, minimum costs are allocated for its construction. The optimal indicator of a finished booth is simplicity, comfort, low cost, aesthetics and inconspicuousness in the yard.

Choosing the location of the dog kennel in the yard

It is optimal to build a portable doghouse for your dog. The landscaping of the yard may change over time, and the kennel will have to be moved. The dog cannot be placed just anywhere. In this matter, they take into account climatic conditions, the location of yard buildings and the characteristic feature of the dog’s breed, that is, its habits.

It’s good if there is a fence, building walls or other structures on several sides near the made kennel that protect the kennel from wind blowing. It’s good when the place with your own kennel is partially shaded. Early in the morning the dog will be able to bask in the sun, and at lunchtime hide from the heat in the shade.

Lowland is not the best place for a dog kennel. When it rains and snow melts, your home will flood with water or there will be constant dampness on the floors.

When choosing the optimal location for the house, you need to remember the instinct of the animal. The dog is inherent in self-preservation and protection of its territory. Even without leaving the kennel, the dog should have a good view of most of the territory through the hole, including the entrance to the owner’s house and the yard. Ignoring such conditions will lead to anxiety in the animal. Whenever a sound occurs, the dog will jump out of the kennel, rattle its chain and bark, which will bring unnecessary anxiety to the owners. But it’s also not a good idea to place a dog’s kennel close to a path where people often walk. Constant noise and movement irritate the animal, causing constant barking in the yard.

Determining the dimensions of the doghouse

Building a dog house with your own hands begins with determining its dimensions, and you can’t go wrong here. The photo shows a table with examples of different dog breeds. The size of the booth and manhole must correspond to the body size of the dog.The animal inside the kennel is provided with enough space to sleep, turn around and stand upright. However, you should not build a large booth with a reserve. In winter, heat will be poorly retained inside such a house, even if the walls are made using insulation.

Taking several measurements of the dog will help you optimally calculate the dimensions of the house:

- The dog is measured by height at the withers. Add 20 cm to the result. This will be the height of the kennel.

- In a lying position, the dog is measured from the tip of the tail to the end of the front legs extended forward. 15 cm is added to the result, determining the depth of the booth.

- The dog should be able to lie across the kennel at full length. The width of the house is determined by the same measurements as the depth. That is, it is optimal when the booth is square.

The entrance to the kennel cannot be a simple hole. The size of the hole should be free for the dog to quickly pass through, and also not very spacious, so that in winter less cold penetrates into the home. The height of the hole is determined by the same measurements of the dog's height at the withers with the addition of 12 cm. Add 10 cm to the measurements of the dog's chest to calculate the width of the hole. The shape of the entrance to the booth is round or rectangular.

We prepare materials for construction

Most often, the owner of a summer house or private yard has a question about how to make a dog house from available material so that it turns out strong, and at the same time incur a minimum of costs. So, the frame can be welded metal, but it is difficult to sheathe it. For these purposes, it is better to use timber with a section of 50x50 mm. Flooring, wall cladding and roofing are made from boards 20–30 mm thick. An OSB sheet will do, but chipboard cannot be used.When heated in the sun, the stove emits an irritating odor for the dog, and when exposed to moisture, it swells and crumbles into small sawdust.

The outside walls and roof of the booth can be covered with galvanized iron or corrugated sheets on top of the boards. It is unacceptable to use plastic lining. The dog will simply tear her apart in a matter of minutes. When making an insulated booth, all structural elements are made double, and foam plastic or basalt wool is placed between them. Waterproofing is made from ordinary inexpensive materials. You can take pieces of roofing felt, film, old linoleum, etc.

Step-by-step production of a dog house

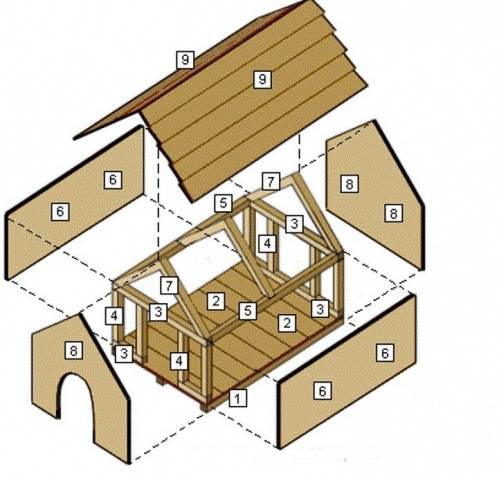

The photo shows a detailed diagram of what parts the booth consists of. Having decided on its dimensions, the drawing can be used to make the structure with your own hands.

So, let’s figure out how to make a doghouse from wooden blanks:

- First, a frame is knocked out of timber. It will determine the dimensions and shape of the entire structure. The frame of the rectangular bottom is knocked down first. Four corner posts are attached to it, and two - forming the opening of the manhole. The top of the rack is tied with timber. That is, the result is the same frame as on the bottom. For strength, the frame is reinforced at the corners with bevels and jumpers are nailed. The corner posts of the frame can be extended 100 mm below the bottom frame. In this case, you will get a booth with legs, and in the future you will not have to put it on stands.

- The floors inside the kennel are laid from boards or cut from OSB boards. If you make an insulated booth with your own hands, then you can cut a piece of OSB onto the bottom frame. Then another frame is stuffed from the slats along the edges of the structure, forming a void. Waterproofing is laid here, then thermal insulation, and floors are made of boards on top.

- The sides of the frame, forming the walls of the dog house, are sheathed with boards or OSB. If insulation is used, the walls of the kennel are made exactly the same way as the warm bottom was made.

- The easiest way to make a roof is a pitched roof. To do this, just nail a couple of bars to the top trim of the frame opposite the hole to form a slope, and then fill the boards. For a gable roof, you will have to knock down two triangular rafters from the timber, and then fasten them to the top frame frame. The resulting slopes are tightly sheathed with boards. It is better to cut triangles from OSB boards for the gables.

- Regardless of the roof structure, it is sheathed with roofing material, since even tightly nailed boards will allow water to pass through. For roofing, it is better to use a material based on sheet metal. Galvanized or corrugated sheeting is suitable. If you use ferrous metal sheets, they will need to be painted periodically to protect them from corrosion.

- The finished dog house is painted with soft paint. The wood can simply be treated with antiseptic impregnation, and then with drying oil or varnish.

When the paint is completely dry, the booth is installed in a permanent place, and the dog is tied next to it.

The video talks about making the booth:

Features of choosing a roof shape

So, we looked at how to build a dog house with a pitched and gable roof. However, novice dog breeders may have a question about what to consider when choosing a roof shape.

It is better to make a gable roof on small booths. Inside the house, this design increases the space, but makes the kennel heavier. A large booth with a gable roof will not be liftable.

A pitched roof is easier to manufacture and much lighter than the previous version. The roof is suitable for a large booth.By the way, it can be made removable, which will allow for better cleaning inside the house.

If the dog from the first moments positively assessed the booth assembled from scrap material, then your work was not in vain.