Content

Today, a heat gun is the best device that can quickly warm up a room. The heater is successfully used in industry, agriculture, construction and at home. The main difference between the devices is the type of energy consumed from which they operate. Today we will talk about thermal gas guns, we will understand their structure and varieties.

The device of a heat gun operating on gas

Gas-powered heat guns are not far behind their electric counterparts in demand. Their popularity is due to the use of clean fuel compared to diesel units. To this advantage we can add high efficiency and minimal emissions of combustion products.

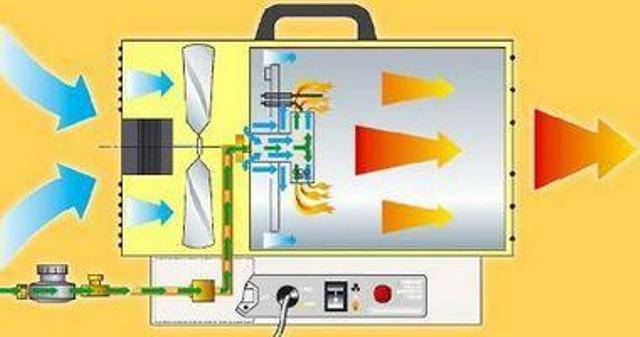

The device of a heat gun resembles a gas burner with a fan behind it. The entire mechanism is contained inside a steel case. Liquefied or natural gas is connected through a reducer. For ignition, almost all models are equipped with a piezoelectric element.

Depending on the model, gas guns are equipped with sensors that improve the comfort of using the device.For example, automation can react to the oxygen level in a closed room or the end of fuel. Almost all gas guns are equipped with a thermostat that automates the operation process. The regulator controls the combustion, as a result of which the flame automatically turns off or turns on when the set temperature is reached inside the room.

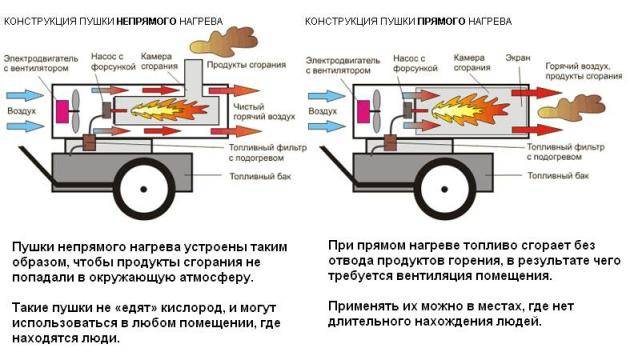

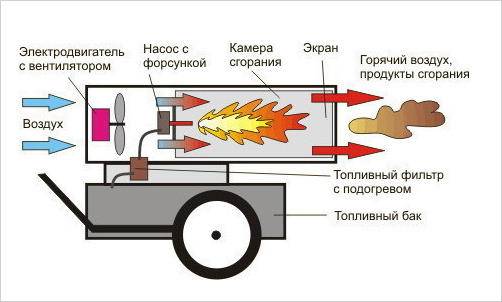

Gas units, like diesel heat guns, are divided according to the type of combustion into two types:

- If the burner flame is isolated inside the chamber, and gases are exhausted through a hose, then this is a gun with indirect heating. The efficiency of the device is less than that of its direct-heated counterpart, but the gun can be used in residential areas.

- When the flame comes out of the gun nozzle along with the exhaust gases, then such a unit belongs to the direct type of heating. The cost of this model is less than its analogue with indirect heating, but the gun can only be used in rooms where people are rarely present.

Now let's look at how a gas gun works. Gas is supplied to the burner through a high-pressure hose through a reducer and an electric valve. Open or closed combustion occurs in a special chamber, behind which a fan is installed. Its blades are driven by a motor powered by electricity. The fan captures cold air, circulates it around the burner, and then pushes it out of the gun nozzle.

The video shows the device of heat guns:

Scope of application of gas guns

The scope of application of the thermal device is extensive.However, you must immediately define clear boundaries of use. Let’s say that an indirectly heated gas heat gun can be used in any room, but a direct heating device is best used where the exhaust gases will not harm humans.

A heating unit with exhaust gas removal can even be installed in an apartment for heating. Although it is reasonable and easier to use electric guns for these purposes. A thermal gas appliance of indirect heating is used to heat large rooms where people are constantly present: train stations, shopping centers, etc. Such guns are often installed in poultry and livestock farms.

Directly heated guns emit less harmful substances when burning gas than diesel engines, but they are not used for residential premises. In the household, you can use the device to dry your basement, warm up your garage, or install it in a semi-open, well-ventilated gazebo. Most often, such a heating device is used in production or construction. The cannon is used to warm up a warehouse, a damp building under construction, an open area, etc.

Hose for gas gun

To operate an indirect heating heat gun, a corrugated hose is connected to the exhaust pipe. Through it, exhaust gases are discharged to the street. There are several types of corrugations, which are used depending on the specifics of the room:

- A rolled hose is a pipe twisted in a spiral from a metal strip. The result is a durable and flexible corrugated sleeve.

- A stainless steel hose is most often used for a small gas gun installed permanently. This option is suitable for heating a garage or home workshop.

- Multilayer hose designed for converter installations. The sleeve provides free access to oxygen and is characterized by increased strength and long service life.

- Corrugated high-pressure hose is often used when arranging heating for industrial premises. The sleeve is able to effectively remove gases even in a bent state.

- The vacuum bellows is made of stainless steel. It is characterized by a high frequency of corrugation.

Before purchasing corrugation, you need to perform a couple of simple calculations and decide on the type of equipment. Let's look at what needs to be done:

- determine what fuel the heat gun operates on: gas or diesel fuel;

- measure the desired sleeve length with a small margin;

- think about the optimal hose diameter;

- decide which sleeve is better to buy: black steel or stainless steel.

When choosing between a stainless steel or ferrous metal hose, it is better to give preference to the first option. Plain metal corrugation costs less, but its service life is similar. Such a hose will quickly rot in damp conditions, and will also burn out faster when exposed to high temperatures.

The stainless steel sleeve is resistant to any weather conditions and aggressive environments. The hose can last a long time outdoors or indoors where vapors of acids and other chemicals may be present. In case of overheating, stainless steel does not lose its properties and remains durable.

Which is better to choose: gas or electric heat gun

For home use, gas or electric heat guns are most often purchased. We will now consider which one is better to choose:

- When choosing a heat gun, you should immediately pay attention to the size of the room that the device is supposed to heat. For small rooms, whether residential or non-residential, a unit powered by electricity is ideal. The heat gun will not harm the health of humans or animals, since there are no harmful emissions. The heating element of the device is a heating element, which can quickly heat up immediately after switching on. Electric guns are sold in different capacities, which allows you to make the optimal choice of device for home use.

- A gas gun should be chosen for heating large rooms. Let's say you have a pigsty, poultry house or greenhouses at home. A gas appliance is more powerful than an electric one and supplies heat faster immediately after switching on.

The choice of heat gun model may also depend on the cost of fuel. However, you need to take into account that even a gas appliance consumes some electricity. The fan and gun automation operate from the mains.

Self-production of a gas heat gun

If desired, do gas heater possible from scrap materials. The heat gun is assembled with your own hands according to the diagram suggested in the photo.

For the gun body you need to take a steel pipe 1 m long and 180 mm in diameter. A combustion chamber made of a shorter metal pipe with a diameter of 80 mm is fixed inside it. On the fan side, the combustion chamber is sealed with a plug, where the burner from the gas stove is attached. The gun is made by indirect heating, so the second side of the combustion chamber is also sealed with a plug. A hole with a diameter of 80 mm is cut in the top of the body. A similar window is cut out in the combustion chamber, into which a pipe for exhausting gases is welded.An electric fan is mounted at the inlet of the housing so that it blows well into the combustion chamber.

To ignite the burner, you need to install a piezoelectric element, and the fan can be started via a switch. The stand is welded tightly to the body or made removable with a bolted connection.

The video shows a homemade heat gas gun:

It must be remembered that gas equipment poses a great danger to humans if used incorrectly. A homemade gun does not have effective protection like factory-made devices. If you desperately need a gas heater, you shouldn't save money by making your own design. It's better to buy a gas gun in a store.