Content

Today, energy sources such as coal and wood are still quite popular. Wood stoves are installed in many homes. Firewood is also used to heat fireplaces and boilers. Most owners of their own plots chop firewood manually, with an ax. However, there is a more modern option - using a wood splitter. This unit simplifies chopping wood and reduces time costs.

To figure out how to construct a wood splitter with your own hands, you should familiarize yourself with the drawings of the device and view several photos of finished products.

How to choose a wood splitter

When choosing a wood splitter that will be used for domestic needs, you should decide how much work you will face. This determines what design the product will be. The first question that faces the owner of a country house is: buy a factory one or assemble the device yourself?

In the case of a purchased product, you will have to shell out a lot of money. For self-assembly, you will need to prepare a set of tools and the necessary materials. However, if you choose this option, you can get by with a minimum of costs.

Types of wood splitters

To understand how different wood splitters work and work, you need to understand their types. This will help you understand the instructions and product diagrams. There are different classifications of such devices. You can assemble a wood splitter with your own hands using video instructions or drawings.

An important characteristic of the wood splitter is the position of the logs. It could be:

- Horizontal - logs are laid on the bed. Then they move towards the cutting tool or the cutting tool itself moves in the direction of the log.

- Vertical - the knife is placed above the log, which allows you to split the material from above. With this type of wood splitter, the log must be fixed.

It can be argued that the efficiency of horizontal products is less than that of vertical ones. However, each device has certain operating features. Designs are also divided by drive:

- On diesel or gasoline. This type of device is the most common. The main advantage of the products is complete autonomy.

- Mechanical wood splitter. It is very durable and reliable. They are used mainly for short-term work.

- On an electric motor. These wood splitters are stationary products. They are convenient, but have average performance.

It also matters what shape the cleaver is made. This indicator also refers to the main parameters of the product. The splitting axes can be conical or cross-shaped. In the latter case, the firewood is split into 4 parts. This is quite convenient if they are used to load into the boiler shaft.However, splitting wood with such a device will require a lot of effort.

Products with cone-shaped cleavers are more popular. You can construct a wood splitter with your own hands very quickly.

Features of products with a cone-shaped working part

The cleaver, which is made in a cone shape, may have a thread. It is used in electrical and diesel wood splitters. Its advantage is the fact that the logs are split using rotational movements of the tip. The cleaver is twisted into a log. For this reason, splitting the workpiece will not require any serious effort.

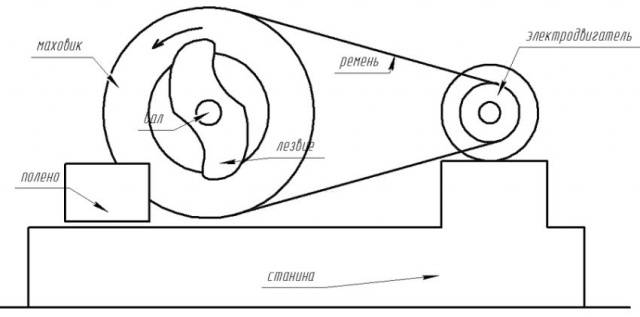

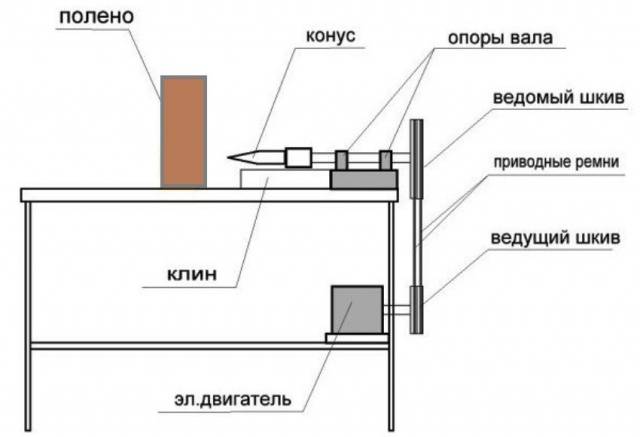

Models that run on electricity and gasoline usually use a cone-shaped cleaver. If you want to design a homemade screw wood splitter, you will need to create a drawing. During work, it is better to follow the previously prepared instructions. Before you create a wood splitter with your own hands, you will need to know its structure.

Such a unit is made of several parts:

- Motor. It can run on fuel or electricity. To ensure the efficiency of the device, the motor must have a power of 1.5 kW. The voltage should be 380 V.

- Bed. This piece is a table with legs. Firewood is placed on it. The engine is installed under the frame.

- Gearbox. It serves to regulate the number of engine revolutions.

When assembling the device, consider its design. The advantage of such a product is its low cost of production. Typically, wood splitters with a cone-shaped splitter are created for domestic purposes.

Hydraulic wood splitters

Hydraulic-type models have one undeniable advantage - they allow you to chop fairly large volumes of firewood in relatively short periods of time. The cleaver in such a device is located on the rod.

When creating a hydraulic log splitter, several features should be taken into account:

- how the log is positioned;

- motor power;

- the force with which a log splits;

- permissible log size.

Assembling a hydraulic log splitter is more difficult than a cone splitter. However, the performance indicators of such devices are much higher.

Thanks to the drawings of the wood splitter, you can understand on what principle it works. Assembling such devices at home is a fairly simple task. To figure out how to make a wood splitter with your own hands, you will need to study a device of a certain type of design.

Rack splitters

They were so called because the cleaver is attached to the rail. The log splits when you press the handle that is included in the wood splitter. In this case, the gears engage, and then the rack begins to move towards the log. As a result, the block splits into several parts.

Homemade rack and pinion wood splitters are characterized by the following parameters:

- cleaver shape;

- minimum log size;

- splitting force of the workpiece.

Rack and pinion structures are often implemented in factory assembly. However, such devices are much more expensive than those made by hand.

Assembling a wood splitter

At home, assembling a wood splitter with your own hands is not difficult. To do this, you will need to prepare certain tools and materials. In the case of different types of products, you will need to take into account their characteristics.

Screw products

To assemble a screw product, you will need to purchase a cone-shaped cleaver, a gearbox and a frame. The last element can be constructed independently from sheet steel and metal corners. You can assemble a wood splitter with an engine with your own hands quite quickly if you follow the instructions.

First, the motor and gearbox are installed on the frame. Then a cone is put on the shaft, and the shaft is connected to the gearbox. When assembling such a device, you must consider:

- The attachment must not be attached directly to the motor.

- If you do not have experience working with electrical equipment, you should seek help from a specialist.

- The belt drive must be covered with a casing.

- The shaft should rotate at 250 rpm.

Taking into account such features, it will be much easier to assemble a screw wood splitter. To figure out how to make a wood splitter, you should get acquainted with the features of its design and operation.

Assembly of the hydraulic product

Designing a homemade hydraulic wood splitter is a little more difficult. This is due to the presence of a hydraulic unit. Before work, you should buy a hydraulic cylinder, as well as a pump and motor for it.

After this, the hydraulic part is installed on the frame. Before starting work, you should evaluate how economically profitable it will be to create such a unit.

conclusions

You can not only design a wood splitter yourself, but also purchase it in a store.The main difference between such devices will be the price. The main advantage of wood splitters that are sold in stores is that they save time and effort.

A video of assembling a wood splitter with your own hands is presented below: