Content

With the onset of winter, private sector owners and utility workers have a new concern - Snow removal. Moreover, it is necessary to clean not only sidewalks, but also the roofs of buildings. Many tools have been invented to perform these jobs. Each snow scraper differs in shape, size, and the material from which it is made.

Types of snow shovels

The most common and familiar snow removal tool for everyone is shovels. The shapes and designs of this simple equipment are constantly being improved. Modern modernized shovels have folding handles, are made from lightweight materials and are even equipped with a wheel.

Let's start our review of snow removal equipment with wooden tools. This shovel is characterized by a wide scoop and a long handle. The classic model can be used instead of a scraper. To prevent the edge of the plywood scoop from fraying, it is framed with steel tape.

Metal shovels are more reliable, but their ease of use depends on the material used. Regular steel is not suitable for tools.Snow saturated with water will constantly stick to the scoop, plus it will be susceptible to corrosion. Galvanized shovels do not rust, as long as the protective coating remains intact. An excellent material for a snow shovel is aluminum. This metal scoop is corrosion-resistant, lightweight, and snow doesn’t stick to it well.

A popular material for modern snow shovels is composite plastic. Snow does not stick to this scoop, it is quite durable, and, most importantly, it is light in weight. Plastic shovels do not corrode and do not become saturated with water from wet snow. The edge of the scoop is protected from abrasion by a steel edge. If treated with care, a plastic shovel will last for five years.

A folding plastic shovel is most often in demand by car enthusiasts. The tool fits in the trunk and can always be taken with you. The handle consists of two parts connected by a hinge mechanism. To fix the elements in working order, there is a sliding sleeve on the handle.

Another version of a folding shovel differs in the design of its handle. It was made telescopic. Such equipment is similarly convenient for transportation in the trunk of a car. You can take a shovel with you to the dacha in your bag.

Have you seen a snow shovel on wheels? Yes, there are such instances. More precisely, the design has one large diameter wheel. It is attached to the handle on the axis at the point where the articulated connection of the two elements of the handle is located.The role of the scoop is played by a plastic bucket, which is a shovel and at the same time a scraper. Bicycle handles are attached to the second end of the handle. While working, a person rolls a tool around the area, and snow is shoveled into a bucket. To unload, simply push the handles down. At this time, the bucket with snow rises and throws it forward.

Snow scrapers

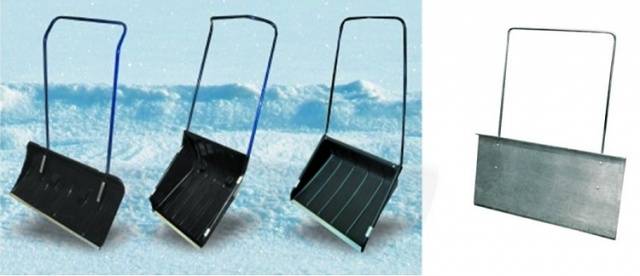

The second popular tool for clearing snow after shovels is scrapers. This type of equipment similarly has a simple design with a handle or a complex mechanism on wheels.

Let's start the review of models with the simplest scraper, called a drag. A snow removal tool also has another name - a scraper. The scraper consists of a wide bucket to which a U-shaped handle is attached. During operation, the scraper is pushed forward by hands. Snow is collected into the bucket, which is then unloaded by tipping the scraper.

For those who want to use the scraper as a shovel, manufacturers have come up with a modified tool. A special feature of the design is the scoop shape. The bucket can be used to shovel and throw snow.

A mechanized snow removal tool is an auger scraper. Its advantage is that there is no need to unload snow. The working mechanism of the scraper is a screw with spiral knives. During rotation, they resemble a meat grinder. A man pushes a scraper in front of him. The rotating auger scoops up the snow and throws it to the side. The tool is only effective for removing loose snow up to 15 cm thick. It will not remove thick and compacted layers.

To clear large areas of snow, a manual bulldozer on four wheels was created. The design of the scraper resembles a cart with a handle. The blade is fixed at the front. The angle of rotation is adjusted by the rod. This mechanized scraper can even handle icy layers of snow.

A manual bulldozer on two wheels is easy to maneuver. The scraper is easy to lift with the handle to overcome ledges on the road. There are models with adjustable and non-adjustable blade angles.

Electric snow scrapers

Electric scrapers help effectively deal with snow drifts. They can be made in the form of a full-fledged snow blower or a small shredder with an extended handle. The working mechanism is a screw. An electric motor is responsible for its rotation. Spiral knives scoop up the snow, crush it, and then throw it far to the side through the sleeve.

Electric scrapers are used for cleaning snow from the roof, but it is impossible to climb onto a pitched roof with such a tool. Snow blowers and manual shredders are used to clear large flat roofs of multi-story buildings and industrial buildings.

Telescopic scrapers for removing snow from pitched roofs

Removing snow from the roof has always caused a lot of problems. It is difficult to climb onto a slippery surface with a simple shovel, and you can even fall off a pitched roof. To solve this problem, there is a special design of scrapers with a sliding handle. The telescopic handle allows you to use a scraper to reach the highest point of the pitched roof directly from the ground. The person extends the handle according to the principle of a folding fishing rod to the desired length.The design of the scraper itself can be made in the form of a piece of rectangular plastic, perpendicularly attached to the handle. The disadvantage of such a scraper is the high labor costs, as well as the risk of getting a head injury from snow falling from the roof.

A telescopic scraper has a more convenient design, the working part of which is made in the form of a frame. A long strip of tarpaulin, plastic or any synthetic fabric is attached to the lower jumper. During work, a person pushes the frame along the surface of the roofing from bottom to top. The lower element of the frame cuts off the layer of snow, and it slides down to the ground along a hanging strip.

Working with a frame scraper requires minimal labor. Even an elderly person or teenager can push the tool. The frame will not damage the roofing. You just need to be careful when approaching the ridge bar. With a strong push of the scraper you can tear it off and then you will definitely have to climb onto the roof.

The disadvantage of a telescopic scraper is its limited scope. The scraper is only needed to remove snow from the roof. It will not be useful for any other work.

Rules for choosing snow removal equipment

An incorrectly selected tool can not only delay snow removal time, but also cause pain in the back and hip joint. Before purchasing or making a scraper, you need to familiarize yourself with the upcoming scope of work. After this, the type of tool is determined, taking into account its design features:

- An important parameter is weight. This is especially true for shovels. It is better to give preference to plastic or aluminum models. The lighter the shovel, the less force you have to put into throwing snow.Scrapers and blades on wheels are easier to move. Their weight rests partly on the person's hands.

- The size of the bucket affects the harvesting speed. The wider and deeper it is, the more snow you can capture in one pass. However, you need to take into account that you will need to increase effort, which contributes to rapid fatigue. The ease of control of the tool depends on the size and shape of the handle. A bad handle will overload the human body when working even with a small ladle.

- The shape and design of the bucket affects the comfort of working with the tool and the quality of cleaning. The working part of all scrapers and shovels comes with one or three sides. The first type of scoop is more designed for shoveling snow. Throwing with such a shovel is inconvenient, since the rear side alone is not capable of holding a lot of loose snow. Additional side walls of the second type of scoop prevent the snow mass from falling out on the sides. There are homemade scrapers even without a back side. They will not be able to throw snow, but only move it forward. When choosing a drag scraper or a plastic shovel, you need to make sure that there are stiffeners. They enhance the strength of the scoop and also serve as skis. These stripes make it easier for the bucket to travel through the snow.

- Edges are usually installed on shovels and scrapers. Aluminum strip is used on plastic and wooden scoops. It protects the working surface from abrasion. The plastic edges are removable. Such nozzles wear out quickly, but they are needed for careful cleaning of paving slabs, roofing, and painted objects. The steel edge is designed to remove frozen and compacted snow.

Taking into account all the considered nuances, you will be able to choose a convenient and effective tool for the job.

The video provides an overview of snow shovels:

Many owners are accustomed to making snow removal equipment themselves. It turns out no worse than the factory analogue, and sometimes even surpasses it.