Content

- 1 Advantages of a cold smoked smokehouse from a barrel

- 2 The principle of cold smoking in a barrel

- 3 Types of cold smoked smokehouses from a barrel

- 4 Preparing the container

- 5 Classic cold smoked smokehouse from a 200 liter barrel

- 6 How to make an electric cold smoked smoker from a barrel

- 7 How to make a cold smoked smokehouse from a barrel with a smoke generator

- 8 What can be smoked in a cold smoking barrel?

- 9 Advice from professionals

- 10 Conclusion

A do-it-yourself cold smoked smokehouse from a barrel makes it possible to cook semi-finished products at home at low temperatures. Anyone can make it, the main thing is to consider in more detail all the manufacturing methods and follow a certain algorithm of actions.

Advantages of a cold smoked smokehouse from a barrel

Among the positive aspects of a homemade smokehouse for cold smoking of products, it is worth noting the following factors:

- ease of manufacture;

- the ability to assemble it yourself;

- cost savings;

- variety of design options;

- high degree of efficiency of the unit;

- ability to work at full capacity;

- the design is suitable for smoking both meat and fish;

- there is no need for additional processing of products.

The principle of cold smoking in a barrel

Unlike hot smoking, cold smoking occurs at low temperatures. The duration of the process can be 2 weeks, everything will depend on the size of the semi-finished products, the method of marinating, preliminary measures, and the type of products. So, for example, processing vegetables and fruits with smoke takes several hours, while cooking meat and fish will take from a couple of days to 2-3 weeks.

The cooking time directly depends on the products used

During cold smoking, it is important to control the amount of fuel. There should be no disruptions or interruptions in cooking, and it is also necessary to monitor the smoke temperature indicators. If such mistakes are made, then the products after smoking will not only taste unpleasant, but will also not acquire a pleasant aroma.

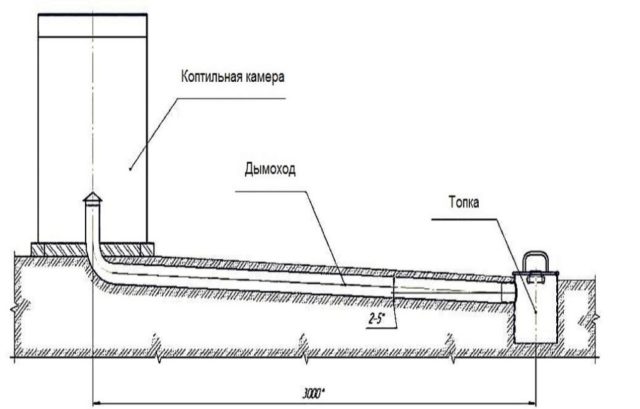

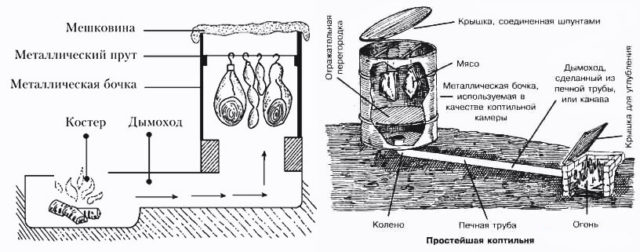

A homemade cold smoked smokehouse from a barrel is a structure consisting of a smoking chamber and a firebox. A chimney is used to connect them.

Types of cold smoked smokehouses from a barrel

There are several main types of cold smoked smokehouses. Each of them has its own operating principle and manufacturing technology.

Electric

The demand for this type of smokehouse is explained by the speed of preparation of semi-finished products. This happens due to treatment with smoke and parallel electrical waves.To make a cold smokehouse from a barrel with your own hands, you will need a set of the simplest materials and tools.

The duration of the smoking process is compensated by the high quality of the finished product

With a separate firebox

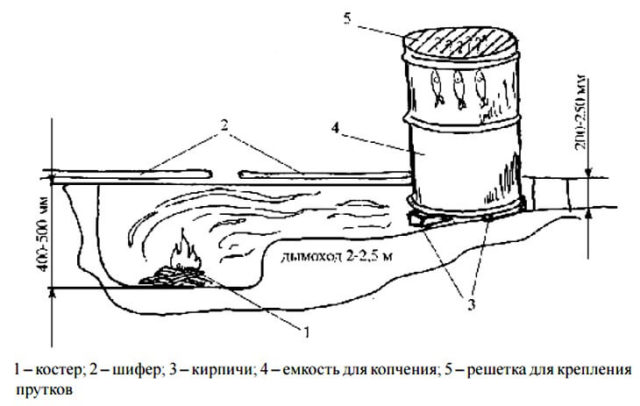

This type of unit for cold smoking of raw materials provides for free space in large sizes. To arrange the firebox you will need a certain distance from the smoking cabinet. The device will be docked with the place where smoke is produced. This is done by using a chimney - a large diameter pipe/hose.

The chimney can be placed both above and below the ground

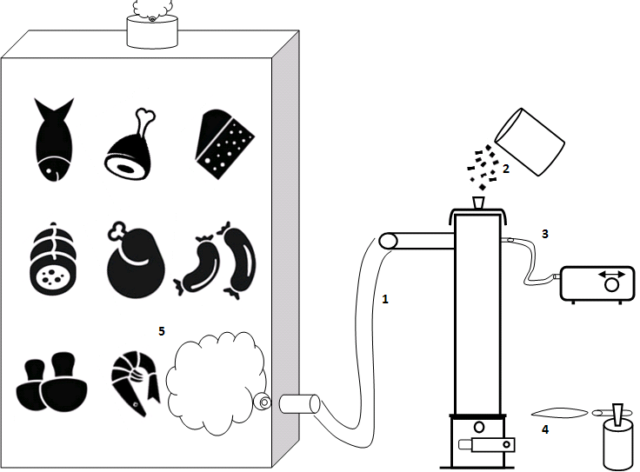

With smoke generator

Unlike the design with a separate firebox, the option with a smoke generator does not require much space. The device for generating and supplying smoke is placed just below the smoking cabinet. Thanks to this, the smoke enters the smokehouse evenly, and food processing is much more efficient.

The advantage of a smokehouse with a smoke generator is the ability to work with minimal control, using wood chips and sawdust to produce smoke.

Preparing the container

To make a cold smoked smokehouse, you need to choose a 200 liter barrel. Such containers are easy to use, have sufficient food capacity, and do not take up much space on the site. Before using it, you need to carry out a number of preparatory measures:

- clean from paint residues;

- burn from the inside;

- to fill with water;

- leave for several days;

- dry thoroughly.

If you ignore these manipulations, the products after smoking will taste bitter and smell unpleasant.

Classic cold smoked smokehouse from a 200 liter barrel

It’s not difficult to make a standard cold-smoked smokehouse with your own hands from a barrel. It is important to know how it works and what steps need to be taken to assemble it.

Operating principle, diagrams and drawings

The unit with a separate firebox is easy to manufacture and convenient to use. For high-quality processing of semi-finished products, it is necessary to monitor the firewood; it must burn uninterruptedly throughout the entire smoking process.

To speed up the assembly of the smokehouse, it is recommended to decide on a diagram, drawing

There are a lot of options, the main difference is in the dimensions of the design.

Often the firebox for a smokehouse is made underground

Tools and materials

To make a smokehouse from a 200 liter cold smoked barrel you will need the following materials:

- metal container with a volume of 200 l;

- slate/corrugated sheet;

- fire brick;

- pipes with a small diameter;

- grate for smoking products;

- small metal sheets;

- hacksaw for working with metal;

- shovel;

- welding machine;

- electric drill.

Marking and cutting containers

In order for the design to have a neat appearance and work at full capacity, it is necessary to place emphasis on the marking of the barrel, determining:

- places to cut the bottom and top;

- opening for arranging a chimney.

Marking when making a smokehouse allows you to eliminate uneven cuts and make the workpiece smooth and neat

It is necessary to cut the container strictly according to the markings, otherwise the tightness of the smokehouse will be “damaged” - smoke will escape outside.

Making handles and lids

If the barrel you are using does not have a lid, you can make one yourself. It is enough to weld a thin metal strip to the cut-off part of the container along the edges for better sealing of the smokehouse.As an option, a sheet of metal is suitable for these purposes; it can be used as is, or you can make a lid from it corresponding to the diameter of the barrel by welding a strip along the edges.

The lid and handle on the smokehouse make the process of smoking products convenient and safe

For convenience and safety of using the smokehouse, it is necessary to provide a handle on the lid. It can be made of wood or metal. Mount it through 2 through holes.

Stand

The presence of a stand for the unit increases its stability and prevents it from tipping over during operation. To make a reliable stand, you will need small diameter pipes joined together using a welding machine. In addition, it will be easier to install a chimney to a smokehouse raised above the ground.

A barrel stand is a simple and effective solution for smokehouse stability.

How to make a firebox and chimney

The process of arranging a firebox involves the presence of a small ditch, where at one end there will be the firebox itself, and at the other - a smokehouse with semi-finished products.

When the trench or hole is dug, it is covered with sheets of slate/corrugated sheeting. But for the convenience of adding firewood for the fire, a lid is made in the pit, but it should not close it tightly. To keep the fire from going out, you need access to air.

If you plan to use the smokehouse for many years, then the trench should be lined with refractory bricks

For the chimney it is necessary to dig a trench; the temperature of the smoke at the outlet will depend on its length. Slate/corrugated boards and boards are laid on top. The chimney is brought to the barrel where the food will be smoked.

Assembly of the structure

To smoke food, you can use a ready-made grill, or one made by yourself from wire. If a sheet of metal is used, then a circle with the same diameter as the container (from the inside) must be cut out of it. To circulate smoke into the workpiece, many holes must be drilled.

A smokehouse from a barrel for cold smoking of products with a separate firebox can also be made from a wooden container

To collect fat at the bottom of the smokehouse, fasteners are provided for a tray. It should not be installed tightly into the barrel, otherwise the smoke will not be able to freely penetrate into the upper part of the tank. Having made four holes opposite each other, fix the rods to hold the pallet.

How to make an electric cold smoked smoker from a barrel

The electric version of the smokehouse benefits in terms of cooking time. The process occurs 2-3 times faster than in the standard design.

Principle of operation

Processing of semi-finished products in a smokehouse occurs as a result of exposure not only to smoke, but also to electrical waves. Thanks to this, they have a longer shelf life. In order for the smoking process to be successful, it is necessary to make the correct connection to the heating element, which was installed in a metal container.

Tools and materials

A heating element from an electric stove is suitable as a heating source for a home smokehouse. The main thing is that when disassembling the tile, the heating element is together with undamaged wires. It is enough to smoke 10 kg of semi-finished products.

The tools you will need are:

- Bulgarian;

- electric drill;

- rivets/screws with nuts.

Assembly of the structure

The process of making an electric smokehouse from a barrel involves the following algorithm of actions:

- Preparing the container. It needs to be cleaned with a metal brush, washed and dried.

- Marking for doors and their arrangement. Some will be for placing semi-finished products in the smokehouse, and the second will be for cleaning up coals and sawdust. It is convenient to cut openings with a grinder, first cut through one side and secure it with hinges, and then modify it further.

- A chimney with a damper is installed in a hole drilled at the top of the barrel. They can be purchased at a specialty store.

- Installation of seals. By fixing thin metal plates, the gap between the smokehouse body and the door is eliminated. For fastening, rivets/screws with nuts are used. To prevent accidental opening of doors, magnets are used.

- Installing brackets under the grille. Several projections can be provided at different distances.

- Installation for thermocouple. First you need to make a hole at the top of the barrel, and then secure the device. You can install a mechanical thermometer nearby.

- Attaching the handle to the door.

- Installing the heating element at the bottom of the tank.

How to make a cold smoked smokehouse from a barrel with a smoke generator

The advantage of this type of smokehouse is the controlled production and supply of smoke into the smoking chamber. You can use a smoke generator ready-made from the store, or assemble it yourself.

Operating principle and drawings

A smokehouse equipped with a smoke generator does not require a lot of free space to accommodate it. The smoke generation device is installed next to the barrel.

In order for the process of assembling a home smokehouse to go quickly and efficiently, you need to prepare a drawing

Tools and materials

To work on the manufacture of a smokehouse with a smoke generator, you need to prepare:

- 200 l barrel;

- a pipe with a diameter of 6 cm and a length of half a meter;

- coupling for thread 40-60 mm;

- grinder;

- drill;

- fasteners.

Assembly

Step-by-step instruction:

- Carry out preparatory measures by clearing the barrel of paint residues.

- Make a glass out of the pipe, narrowing one of the sides and providing a thread for the coupling. The second end of the pipe must be sealed. Join 2 elements into one structure.

- At the bottom of the barrel, weld a coupling onto which the smoke generator will be installed.

- At the top of the future smokehouse, drill several holes for the rods.

- Attach a glass filled with sawdust for smoking to the coupling.

- Install a grill or hang hooks.

- Cover the barrel with wet burlap or tarpaulin.

What can be smoked in a cold smoking barrel?

In a smokehouse from a 200 liter cold and hot smoked barrel you can cook absolutely any product: meat, fish, cheese, sausages, lard. Both fruits and vegetables can be smoked. To obtain the desired effect, it is necessary not to violate the technology of the process of processing semi-finished products with smoke, and to adhere to the chosen recipe.

Before smoking fish, it must be salted. There are many options, the most standard is to process the raw materials with coarse salt. Simply sprinkle it well over pieces of fish and keep them at room temperature for 4 days. To salt a frozen semi-finished product, you need to increase the time by another 1-2 days.

After this, the fish should be soaked in a container of water for 10 hours. At this stage it is important to completely remove excess salt. When the product is soaked, it is wiped with a napkin and hung in a cool place to dry.If smoking is carried out in the summer season, it is recommended to take care of protection from flies and other unwanted “guests” in order to avoid negative consequences. Dried pieces of fish are sent to a barrel for smoking.

The temperature in the room where semi-finished products are prepared should be within +6 °C. In warmer conditions, there is a high probability that they will deteriorate, and in cold air, the process of salting raw materials will not work properly.

Advice from professionals

Anyone can cook smoked meats at home if you follow the following recommendations:

- Control the smoldering process. In order for the products to be evenly processed with smoke, the sawdust should not burn, but only smolder.

- Avoid smoldering intermittently. This process must be uninterrupted; wood chips must be regularly added to the firebox and smoke generator. Otherwise, such failures will significantly worsen the taste characteristics of the finished products.

- The filter must be periodically moistened if it is provided in the unit.

- To retain smoke for a long time in the smoking chamber, it must be covered with damp burlap on top.

- It is recommended to wash the barrel after each use. Otherwise, the accumulated soot the next time you add food will make it bitter and tasteless.

- To ensure that the coals do not interfere with the flow of smoke into the barrel, they must be removed periodically.

- Place a smokehouse made from a barrel for cold smoking of products, made with your own hands, under a canopy. It is both convenient and practical. You can smoke meat or fish in any weather conditions.

- The taste and aroma of finished smoked meats is greatly influenced by the type of fuel. Preference should be given to fruit wood; coniferous wood should not be considered at all due to the abundance of resin released.Sawdust from cherry, apple, oak, and alder have proven themselves best. Juniper will add zest to the products; one branch is enough for one go. If you use coniferous wood chips, the products will have a bitterness, unattractive appearance, and odor. Birch branches can be used, but only after removing the bark.

- It is necessary to add fuel to the firebox in equal portions, this will ensure continuous smoldering and uniform flow of smoke into the smoking chamber.

Conclusion

A do-it-yourself cold smoked smokehouse from a barrel is easy to make. The main thing is to choose a suitable metal container, decide on the design option, and strictly follow the step-by-step instructions for its manufacture. You can smoke completely different products, from meat to fruits. To simplify the assembly process, you need to decide in advance on the design of a cold-smoked smokehouse from a barrel and select the necessary materials.