Content

A motor cultivator is a universal piece of equipment that can be used to perform many household jobs. The unit is in demand even in winter for snow removal, only you need to connect the appropriate attachments to it. Now we will look at the process of making a snow blower from DIY motor cultivator, and also find out what attachments are still used for work in winter.

Types of snow removal attachments, their operating principle and manufacturing procedure

The variety of snow removal equipment for motor cultivators is not that great. The most effective is the rotary hitch. You can also remove snow with a plow. This shovel is usually paired with a road brush, but at home the latter type of attachment is rarely used.

Shovel blade for snow removal

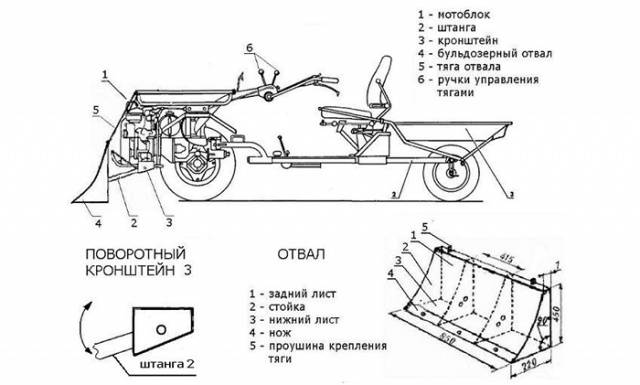

The simplest snowblower for a cultivator is a blade.Although, it is more reasonable to use a bulldozer with a walk-behind tractor, since it has a more powerful engine. But you can also weld a small shovel for a motor cultivator. It is very easy to work with such a hitch. The blade is attached to a bracket on the cultivator frame. While the equipment is moving, the shovel scrapes up the snow cover. To ensure that the snow goes to the side and does not accumulate in a large pile, the shovel is placed at a slight angle relative to the side of the road.

For a motor cultivator, the blade is made of a steel sheet 3 mm thick. However, it is very difficult to bend a metal workpiece yourself without the appropriate equipment. It’s easier to find a piece of steel pipe with a diameter of 200–300 mm, divide it lengthwise into three parts and cut out one semicircular segment with a grinder.

The lower part of the shovel is a knife. It will cut off a layer of snow. However, a steel knife can damage paving slabs or asphalt. For such work, it is necessary to cut a strip from the conveyor belt and bolt it to the bottom of the blade.

On the back side of the shovel, 2 eyes are welded at the top, and rods going to the control levers are attached to them. Eyes are also welded in the center of the blade. A rod is attached here, with the help of which the hitch is fixed to the bracket on the cultivator frame. The bulldozer assembly is completed, you can try shoveling snow.

Rotary snow removal attachment

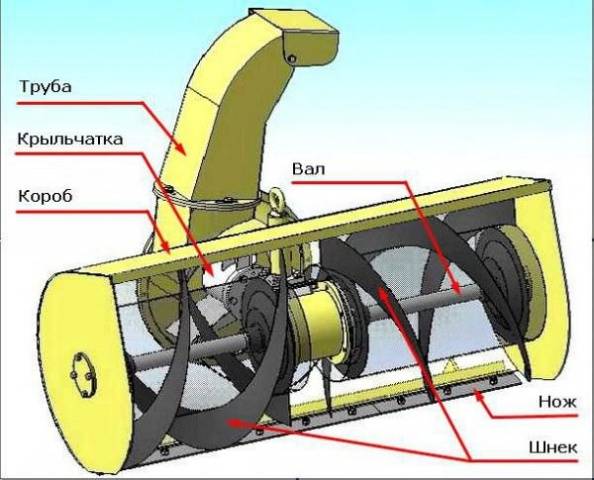

To make a rotary snow blower from a cultivator, you need to do a lot of turning and welding. This type of hitch is also called an auger hitch. The mechanism consists of a steel case. The auger rotates inside on bearings. The spiral-shaped knives grab the snow and push it from the sides of the body towards the central part.At this point, metal blades rotate on the rotor. They pick up the snow and push it through a nozzle mounted on the body of the snow blower. The direction of departure is controlled by the visor. To do this, put a sleeve over the nozzle exit. A rotating visor is attached to the top. The operator himself turns it in the desired direction.

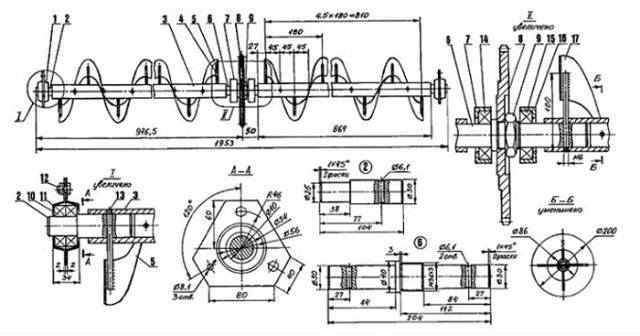

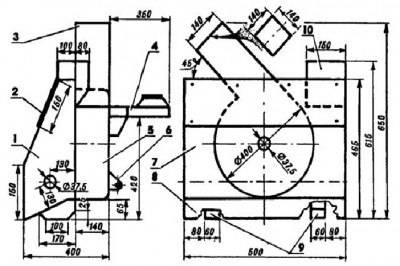

The most difficult part to manufacture is the screw. It’s easier to find it ready-made from old agricultural equipment. Otherwise, you will have to do turning and welding work. The screw assembly is carried out according to the presented drawing. First, take a piece of pipe with a diameter of 20–25 mm. Trunnions are attached to both ends. The knives are made from sheet steel 2 mm thick. To do this, cut out 8 halves of disks. They are welded to the pipe so that a double-sided spiral is obtained. Metal blades are welded in the center of the rotor between two spirals.

After making the auger, they begin to assemble the snow blower body. Its fragments are cut from steel sheet 2 mm thick. A steel strip is attached to the bottom of the body, acting as a stationary knife. It will cut layers of snow. To make the snow blower easier to move through the snow, the body is placed on runners called skis. A pipe from a piece of pipe is welded into the top center of the body. This will be the outlet for throwing out the snow.

Further actions are aimed at installing the auger. First, bearing housings No. 203 are bolted from the inside to the side walls of the housing. After this, the auger itself is installed. The transmission of torque from the cultivator motor to the rotor is organized using a belt drive.Here you need to install the driving and driven pulley. It is advisable to consider a tension system. It will help you adjust the gear to avoid belt slipping.

The casing with a rotating visor for snow ejection is bent from galvanized steel. Rods are attached to the rear of the rotary snow blower body, with the help of which coupling with the motor-cultivator is ensured. During operation of the mechanism, snow will fly out of the sleeve at a distance of 3–5 m. The ejection range depends on the speed of the auger and the angle of inclination of the rotary visor.

Featured in the video homemade rotary snow blower:

Fan snow blower for motor cultivator

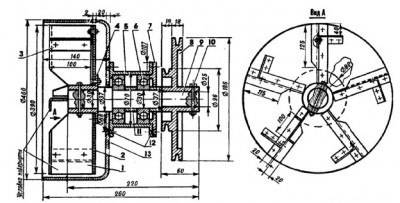

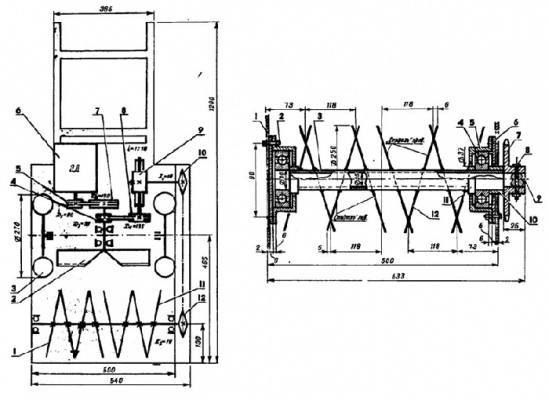

According to the presented drawings, you can make a fan-type snow blower. First, an oval body is welded from sheet steel. This shape is needed for the fan to suck up snow. A bushing for bearings is installed in the hole in the rear part of the housing. There will be 4 of them in the snow blower. Two bearings are mounted on the shaft, after which they are inserted into the sleeve. One end of the shaft should extend outside the housing. Two more bearings with a cup are mounted here, to which mounting brackets are welded. The end of the shaft should also protrude from this side.

The rotating mechanism of the snow blower is ready. Now the fan blades are mounted on the shaft protruding inside the housing. The front of the impeller is covered with a protective steel mesh. A pulley is mounted on the outer end of the protruding shaft. A belt drive from the working shaft of the motor cultivator engine will fit here.

Now you need to organize a hole for snow release. To do this, a wide hole is cut at the top of the oval housing near the fan impeller. A pipe is welded here, and a tin sleeve with a visor is put on top.The rotating fan blades will draw snow into the housing and throw it out through the sleeve under pressure.

The disadvantage of a fan snow blower is the limited use of the attachment. The fan is capable of sucking only freshly fallen loose snow. If the cover is compacted, frozen or wet, then such a snow blower will not work.

Combined snow blower for motor cultivator

Craftsmen who love to invent something special have combined a rotary and a fan snow blower into one design. The result is an effective attachment. In such a snow blower, the auger mechanism cuts off compacted and wet cover. The blades throw the snow into the nozzle, where a running fan pushes it through the sleeve with air. The effectiveness of using a combination snow blower lies in increasing the throw range.

When making this attachment, the rotary snow blower is first assembled. The output nozzle on the body is welded to a large diameter. Additionally, a ring is fixed on the side into which the rotor with fan blades is inserted. A sleeve with a rotating visor is put on top of the nozzle. The rotation of the fan and auger is organized from the cultivator engine through a belt drive. It may be necessary to install three-groove pulleys on the shafts.

Conclusion

The cost of a homemade snow blower will cost the owner many times less than purchasing a factory-made attachment.