Content

A milking machine for cows at home can be made by a specialist who understands how it works and what components it consists of. A home-made unit can cause injury to the udder. If you decide to go with a homemade product, you need to buy factory-made components for the milking machine. At home, spare parts are assembled into one structure.

The operating principle of the milking machine

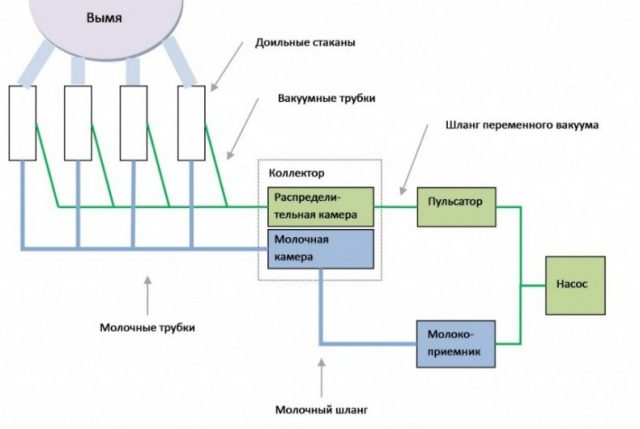

Before you understand the principle of operation and begin manufacturing, you need to understand what main components the milking machine consists of:

- milking cups – 4 pieces;

- hoses for pumping milk and pumping air;

- metal milk collector;

- pump with electric motor;

- collector.

Depending on the model, the device is equipped with a pulsator or a piston pump works instead. The second type of unit consists of a set of valves that are equipped with a milk collector (can) and a pump. Their alternate operation is associated with the direction of movement of the piston.

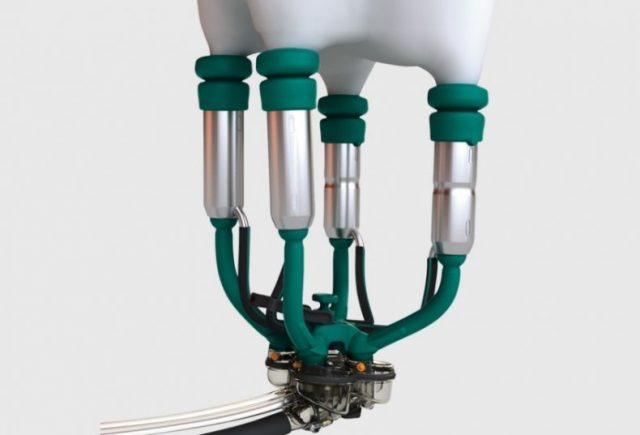

Milking cups have a complex structure. The basis is a metal or plastic case.There are rubber inserts inside. The elastic element tightly covers the cow's udder teats. There is a sealed chamber between the body and the inserts.

Two hoses are connected to each glass. A thick tube for suctioning milk is connected to a rubber insert. A thin hose is connected to the body of the glass. Air is forced through it into the sealed chamber.

The operating principle of a push-pull installation is as follows:

- The glasses are placed on the cow's udder teats and the pump is turned on;

- Initially, low pressure is maintained inside the rubber insert of the cup (the nipple chamber). When the pump activates the pulsator or valve (depending on the design), the vacuum begins to pulsate. With the simultaneous formation of low pressure in the sealed interwall and sub-mammary chamber, milk flows out of the cow's udder teat.

- Thick hoses carry the milk through a manifold into the can.

The flow of milk stops when the pressure inside the inter-wall sealed chamber equalizes to atmospheric pressure.

Almost all units are vacuum and operate on the same principle. Specifications and details differ for different models.

There is such a thing as discontinuous milking. The principle of a push-pull milking machine is based on the constant suction of milk from the cow's udder. The unit has only two operating modes: milk suction and nipple compression. Three-stroke devices work on a similar principle, only there is a third rest mode. For a cow, this option is physiologically more convenient, as it resembles hand milking.

Most modern milking machines are push-pull. They are lighter and easier to transport. Three-stroke models are powerful, usually permanently installed.

The devices differ in the way they milk a cow:

- Suction models suck out milk using a vacuum. The advantage of the technology is the careful treatment of the cow's teats and udder itself. The process closely resembles manual milking.

- Squeeze models operate using vacuum and additional excess pressure.

Suction devices are produced on an industrial scale, and squeezing units are made to order.

Milking units differ according to the method of transporting milk. At home and on small farms, mobile devices with a can are used. On large farms, milk is collected in a large stationary container and transported through long pipelines.

Pros and cons of a home milking machine versus a purchased one

Having decided to make a milking machine at home, you need to compare the pros and cons of a homemade and factory-made unit. Based on the results, make a final decision.

Homemade advantages:

- lower cost if you assemble the units yourself at home;

- the ability to adjust the milking machine layout with your own hands to suit your needs;

- assembly of units taking into account personal requirements;

- independent future maintenance of the milking unit and its repair at home.

Disadvantages of homemade products:

- there is no guarantee of reliable operation of the device, gentle milking of the cow’s udder;

- To properly install components at home, you need knowledge and experience;

- the savings are small, since all components will have to be purchased;

- installation of complex parts will require technical decisions.

Advantages of a factory-made milking unit:

- guaranteeing reliable operation of the device, reducing the risk of injury to the cow’s udder;

- manufacturer's warranty service;

- the purchased installation is immediately ready for operation without testing procedures;

- aesthetic appearance, compactness of the device.

Disadvantages of a factory-made machine for milking cows:

- the high price is not always affordable for a private cow owner;

- some design components may not meet consumer requirements;

- Sometimes you will have to invite a service center representative for service;

- Post-warranty repairs are more expensive for the owner.

After weighing all the pros and cons, it will be easier to decide what is better, make a manual milking machine or buy a ready-made unit.

How to make a milking machine with your own hands

To assemble a homemade product at home, you first need to buy all the components. You will need:

- vacuum type pump;

- hanging mechanism;

- pulsator;

- can;

- a set of hoses for pumping milk and pumping air.

After purchasing all the parts, they begin to develop the project. You can take a factory milking machine as a basis. The diagram is completely copied or their own adjustments are made. First of all, the design of the frame is determined, and then all the components are placed on it.

The functionality of the cow milking machine depends on the choice of components. The unit must comply with the technical specifications. Quality will affect longevity of use. It is advisable to pay attention to cost. Some spare parts from domestic manufacturers are not inferior in characteristics to imported analogues, but are cheaper.

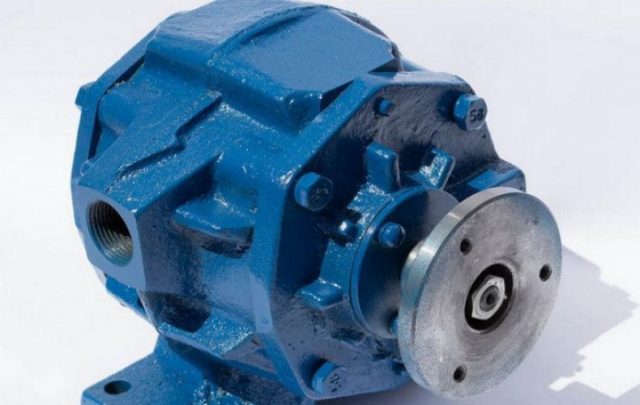

The vacuum pump is the main working unit of a homemade device. The quality of milk suction from the cow's udder teat depends on its work. The choice of pumps is huge. First of all, preference is given to trusted manufacturers. According to the pricing policy, they choose the golden mean. A high-quality pump cannot be cheap. The unit is too expensive and difficult to provide after-sales service.

In order for the machine assembled at home for milking cows to work stably, we begin to select a pump according to technical parameters. The first step is to determine the power. A 500 W pump is enough to milk two cows. If the farm consists of a large number of livestock, pumping equipment is selected with a power of 4 kW or more. Here it is important to adhere to a simple rule: the greater the number of cows, the more powerful the pump is needed. However, a large supply is also not needed. Unclaimed power will result in unnecessary energy consumption.

The second important technical parameter is functionality. There are vacuum and oil pumps. For a homemade milking machine, the first option is suitable. Oil units create high-pitched noise that disturbs cows. In addition, constant monitoring of the oil level is required. If the system is depressurized, the milk will be spoiled.

The suspension unit is an equally important part of the device. It is he who will be in contact with the cow's udder. You can't save money here. It is better to purchase an expensive hanging unit from a well-known manufacturer. It is advisable to choose transparent glasses in order to see the process of milking the cow's udder teats. High-quality rubber inserts and soft silicone suction cups are important. The better these elements, the less power the engine needs to pump out milk.In addition, the cow's teats and udder are less likely to chafe.

The pulsator and collector are chosen at your discretion. This will require personal experience and recommendations from sellers. The units are sold in separate versions and combined ones - pulse collectors. The second option for a homemade milking machine is more profitable. The combined unit is characterized by lower cost, ease of installation and maintenance. The manufacturer does not play a special role. However, imported pulse collectors have a longer service life, but are more expensive. Domestic models wear out faster, but the price is lower. Let the cow owner decide for himself what is more profitable for him.

The hose for transporting milk is chosen to be transparent and made of food-grade polymer. For air, an opaque hose is suitable, but similarly made from non-toxic materials. Pipelines must be strong and wear-resistant.

The container for collecting milk can be plastic, aluminum or stainless steel. The aluminum can is lightweight, but over time it collapses due to dampness. Oxidation products end up in milk. Stainless steel is an ideal material, but the container is heavy. The plastic product does not oxidize, it is light, but it bursts upon impact. The choice of can type depends on the owner’s preferences.

When all the components have been purchased, assembling a milking machine for cows with your own hands will not be difficult:

- the frame is welded according to the developed project;

- a pump and a motor are bolted to the frame, the pulleys are connected with a belt to transmit torque;

- pumping equipment is covered with a metal casing;

- Milk hoses are connected to the pump to pump milk into the can;

- hoses are connected to the starter collector, the suspension unit is connected;

- A hole is drilled in the lid of the can and a valve is installed that is responsible for regulating the pressure.

After assembly is completed, try to start the pump.

The video shows a do-it-yourself milking machine in more detail:

DIY milking machine from a vacuum cleaner

A vacuum cleaner can replace the vacuum pump, but the pressure in the homemade product must be pulsating, otherwise it will cause injury to the cow’s udder. An electric valve is installed on the assembled apparatus from a vacuum cleaner, powered by a pulsed voltage supply. During operation, the valve will bleed air from the hose, creating a pulsating pressure.

The video shows an example of making a vacuum pump from a vacuum cleaner:

Homemade milking machine from a compressor

The compressor will be converted to a vacuum pump. At the inlet to the receiver, a check valve is pulled out from the tee. To remove the rubber coin, you need to unscrew the plug.

The process of making a milking machine from a compressor with your own hands is shown in more detail in the video:

Difficulties and nuances of making a homemade milking machine for cows

The difficulty of assembling a cow milking unit at home arises in the absence of knowledge and experience. Mistakes made will primarily affect the animal. If a cow is frightened or injured, problems with normal milking will arise in the future.

In a homemade milking machine, it is important to take into account all the nuances so that its technical parameters do not differ from the factory design. They even take into account the noise level of the motor and the method of moving the unit around the barn.

Conclusion

It is optimal to assemble a milking machine for cows at home when there are several broken factory-made units. Working parts are removed from each installation and installed on a finished frame.Buying all new components is not economically profitable, and sometimes it will even be more expensive than a new device.