Content

The arc greenhouse is in great demand as it is suitable for greenhouses and open ground. The factory design is manufactured in lengths from 4 to 10 m, which allows you to select the appropriate model according to the size of the site. For home gardening, greenhouses made of arcs with covering material You can buy ready-made ones or make them yourself.

The design of an arc greenhouse and its purpose

A greenhouse made of arcs is an arched frame covered with a special material. Non-woven fabric or film is used as a cover. The distance from the ground to the top point of the arc is considered the height of the greenhouse. This figure varies from 0.5 to 1.3 m, which depends on the type of plants grown. The optimal width of the arc greenhouse is taken from 0.6 to 1.2 m. The length of the structure depends on the distance between the arcs, as well as their number. Factory-made models, the length of which is 4.6 and 8 m, are in great demand. When making a shelter for a bed from arcs with your own hands, you can make any length. However, an oversized design is less stable in the wind, especially if it is made on PVC arches.

These photos show the purposes for which arc greenhouses are used:

- In cold areas, heat-loving crops are grown under cover throughout the season. The dimensions of the greenhouses are selected taking into account the fact that the plants will grow and they should have enough free space. The covering material on the arches is fixed with special clamps so that the canvas can be easily lifted for convenient access to the bed.

- Temporary shelter is used to adapt the planted seedlings to the outside temperature. The canvas protects plants from night frosts and the scorching sun during the day. For these purposes, a prefabricated greenhouse is suitable, which can be easily installed outdoors or in a greenhouse. After the seedlings have adapted, the shelter is dismantled.

- Outside and inside the greenhouse, greenhouses are used for growing radishes, seedlings of cold-resistant crops, and early green salads.

- Prefabricated shelters are convenient for temporary installation on beds with sown seeds. For example, carrot or parsnip grains take a long time to germinate, but under temporary cover the process is doubled.

- Using a prefabricated greenhouse helps save plantings from massive pest attacks. The timing of their appearance is different for each crop, so collapsible shelters are used periodically, but throughout the season.

- Not only children, but also birds love to eat ripe strawberries. Prefabricated greenhouses installed above the garden bed help save the harvest. To provide air access and allow bees to pollinate strawberry flowers, the ends of the frame are only covered halfway.

Factory greenhouses are assembled from arcs with covering material quickly and easily. Pegs included. They are simply driven into the ground and arcs are attached to them. The covering sheet is secured with plastic clips.Some models are made with arches sewn inside non-woven fabric. Assembling such a greenhouse is generally not difficult. It is enough to stretch the structure along the bed and drive the arcs with pegs into the ground.

Arcs and other elements for factory-made greenhouses

A factory-made greenhouse made of arches is equipped with arches of a certain size and the required number, which depends on the dimensions of the structure. However, each item can be purchased separately and not as a set. This allows you to make a shelter of suitable sizes for your site.

Separately sold arcs for factory-made greenhouses are made of the following material:

- Metal arcs are made of elastic wire with a cross-section of 5–6 mm, covered with a PVC sheath.

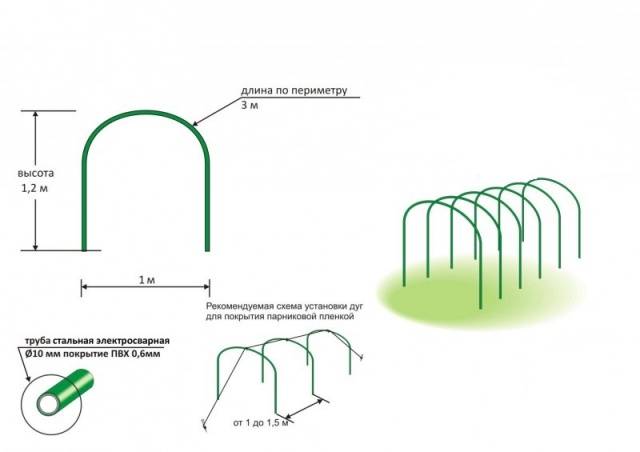

- Another type of metal arches for a greenhouse are arches made of steel tubes with a cross-section of 10–12 mm. To protect against corrosion, the arcs are covered with a PVC sheath.

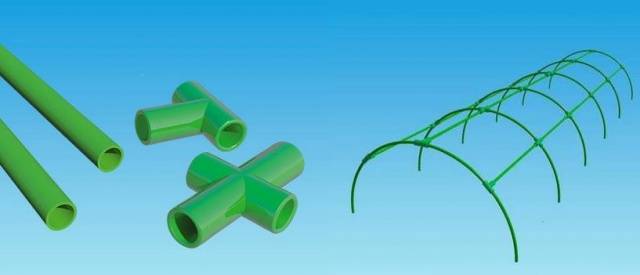

- The cheapest are plastic arcs for a greenhouse, made from a pipe with a diameter of 20–25 mm.

To decide which arches are best to choose from, you need to consider the properties of each material. Metal is a durable and reliable material. The PVC shell protects the arch from corrosion, which significantly increases its service life. Metal arcs are easily stuck into the ground, and you don’t have to worry about them being bent during installation.

The plastic pipe is quite flexible. This allows you to give the arch the required width and height, guided by the dimensions of the bed, as well as the growth of plants. It is difficult to insert a plastic pipe into the ground, as there is a risk of breaking it. Such arcs are attached to pieces of reinforcement driven into the ground or commercial factory-made pegs.

The covering sheet is fixed to the arches with plastic clips.They can similarly be purchased separately according to the number of arcs purchased. To secure the covering sheet to the ground, special pegs with clamping rings are purchased.

Review of popular models of factory-made greenhouses

A ready-made greenhouse made from factory-made arcs is designed for certain dimensions of the bed. The kit includes frame elements and fasteners. Many kits are equipped with canvas according to the size of the greenhouse. You cannot independently change the distance between the arcs in a finished greenhouse, especially if they are sewn into the fabric. Now we will look at photos and a brief description of popular models of factory greenhouses.

Dayas

The design of the shelter for Dayas beds consists of plastic arches sewn inside the canvas. Arcs 2 m long are made of pipe with a cross-section of 20 mm. To install the arches, a 200 mm long peg is inserted into the end of each pipe. It is enough to stick them into the ground and compact them well. The frame is made of sections. This design allows you to install a shelter 4 or 6 m long. When assembled, the width of the greenhouse is 1.2 m and the height is 0.7 m. Convenient access to the plants is provided from the sides of the greenhouse by lifting the canvas up along the arcs.

The included 2.1 m wide covering sheet is sewn to plastic arches and moves easily along them. Additionally, plastic clips are supplied. When watering the beds, they fix the raised canvas on the arches, preventing it from falling.

The video shows the Dayas greenhouse:

Agronomist

This model of shelter for beds is made of plastic arches, for which a pipe with a cross-section of 20 mm was used. A 200 mm long peg is inserted into the end of each pipe. The arches are made 2 m long. The height of the assembled structure can be in the range of 0.7–0.9 m. The sections allow you to make a shelter 4 or 6 m long. Agrotex-42 is used as a covering fabric.

Precocious

The prefabricated type of greenhouse is produced in several varieties of models, differing in the size of the arcs: width - 1 or 1.1 m, length of the arches - 3 or 5 m, height of the finished structure - 1.2 or 1.6 m. The arcs are made of an elastic metal rod covered protective polymer shell. The product includes 4 or 6 arches, which depends on the size of the greenhouse, 1 or 3 crossbars, clamps, pegs and fixing rings for the canvas. The frame is assembled quickly, using the method of installing arches in the ground. The arcs are connected to each other by a crossbar.

Hawk

The greenhouse model is equipped with 7 arcs made of HDPE pipes with a cross-section of 20 mm. When assembled, the length of the shelter is 6 m and the width is 1.2 m. The set includes 15 pegs with a length of 250 mm, clamps for the canvas and SUF-42 spunbond with dimensions of 3x10 m. The model is intended for outdoor use and inside the greenhouse. During installation, the arcs are bent to the required semicircle size and stuck into the ground using pegs. The covering sheet on the arches is fixed with clamps, and pressed to the ground with any available weight.

Making your own arc greenhouse

For a homemade design, make arcs for a greenhouse with your own hands from any plastic pipe with a diameter of 20 mm.An elastic metal rod with a cross-section of up to 10 mm or a flexible hose will do. In the latter version, the strength of the arch is given by reinforcement. To do this, insert a wire with a cross-section of 6 mm or a long rod made of wicker inside the hose.

Making a homemade greenhouse follows the following steps:

- Before making arcs for a greenhouse, you need to decide on their size. The width of the arch is 1.2 m. The height depends on the growing crops. For example, for cucumbers this figure is 80 cm, and for semi-determinate tomatoes - 1.4 m.

- A rectangular box the size of the bed is made from a board or wooden beam. For work it is better to use oak or larch. Such wood is less susceptible to rotting. The optimal height of the sides of the box is 150 mm. The finished frame is installed in place of the future bed.

- Arcs made from plastic pipes are very flexible and can bend in strong winds. Strengthening the frame will help to cope with the problem. Two racks are installed in the center of the ends of the box made of timber with a cross-section of 50x50 mm. They are connected to each other by a board. In the resulting crossbar, holes are drilled with a diameter 2–3 mm larger than the thickness of the arcs.

- Pieces of the required length are cut from a plastic pipe and inserted into each hole of the crossbar. Now all that remains is to bend the arches from them and secure the ends of the pipes to the box. Fixation to the sides of the frame is carried out using clamps screwed with self-tapping screws or perforated metal tape. Alternatively, you can hammer pieces of reinforcement into the ground and put arcs on them.

- According to the size of the ends of the frame with an allowance of 200 mm, 2 fragments are cut out of the covering fabric. The material is fixed to the pipe with plastic clamps. Next, a large piece is cut out of the canvas with an allowance of 500 mm to fit the size of the entire greenhouse.The material is laid out on the frame, fixed to the pipes with clamps. The canvas can be additionally nailed to the top wooden crossbar through an overhead lath.

The covering sheet is pressed to the ground with any weight without sharp edges. Otherwise, the material may tear during the wind.

The video shows the making of a greenhouse:

User reviews

Feedback from ordinary people often helps you choose the right greenhouse model. Let's find out what they are talking about on garden forums now.