Content

- 1 Pros and cons of a transforming bench for a summer residence

- 2 Types of country transforming benches

- 3 What is needed to assemble a transforming bench

- 4 Drawings and diagrams for assembling a transforming bench

- 5 Dimensions of the transforming bench

- 6 How to make a transforming bench with your own hands

- 7 Design of a folding transforming bench

- 8 Conclusion

- 9 Reviews about the transforming bench

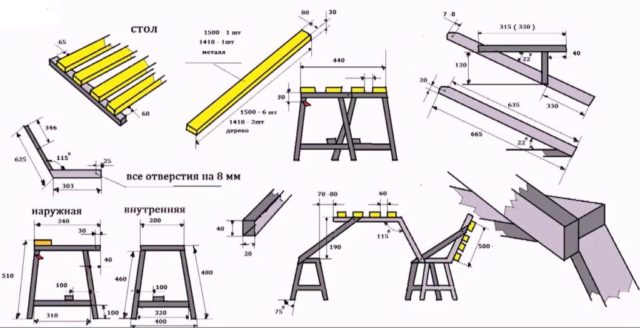

Drawings and dimensions of a transforming bench will definitely be needed if you want to make such unusual garden furniture. Despite its simple design, the design is still considered complex. It is important to correctly calculate and make all the nodes so that the transformer can be folded and unfolded freely.

Pros and cons of a transforming bench for a summer residence

A folding bench is in demand among summer residents and owners of country houses.

The popularity of the transformer is due to the advantages:

- The main advantage is its compactness. The bench when folded takes up little space. It can be placed against a wall or simply along the sidewalk path.

- They try to make the transformer from light and durable materials.Due to its low weight, the bench can be easily moved to another place.

- The third advantage is the possibility of turning a bench with a back into a table with two benches without backs. The transformer will help out in nature when you need to organize a feast for guests.

The unusual bench also has some disadvantages:

- To assemble a transformable bench table with your own hands, you will need drawings with exact dimensions. If an error is made in the diagram, the structure may not unfold or fold completely.

- The use of thick-walled pipes or an array of hardwood trees increases the weight of the bench. It becomes more difficult to unfold. It will be difficult for only two people to move the transformer to another place.

- Over time, due to frequent use, the moving parts of the bench weaken and play appears. The transformer becomes shaky.

After weighing all of the above factors, it is easier to decide whether such a bench is needed at home.

Types of country transforming benches

Most folding benches are designed according to the same principle. The size varies, which determines the number of seats. Another nuance of transformers is the structure of the frame, moving parts, and material of manufacture.

If we talk about the differences between benches in terms of general design, the most common options are:

- A transformable table and bench for a summer house, which is easy to unfold in 1-2 seconds, is considered a classic. When folded, the structure takes up little space. They use it instead of a regular comfortable bench with a back. After unfolding, the transformer has a tabletop with two benches opposite each other.

- The transformer constructor is a frame made of pipes, where L-shaped wooden parts are strung on a long crossbar.They rotate freely, and the elements are fixed in the desired position. The designer allows you to perform four combinations: turning into a long bench with a back, two wide chairs with armrests or two narrow chairs and a table between them, one chair with a table on the side.

- The transformer with the unusual name “flower” resembles piano keys. The design consists of a large number of planks, some of which rotate on the crossbar of the frame. When folded, it turns out to be an ordinary bench, convenient for transportation. To relax comfortably, just lift some of the slats and you will get a comfortable backrest of the bench. The advantage is that the raised petals can be fixed at any angle for a more comfortable position of the resting person’s back.

There are other types of folding benches, for example, radius ones. However, such transformers are rarely in demand due to the complexity of the device and inconvenient shape.

What is needed to assemble a transforming bench

The folding design is considered difficult to manufacture. First of all, you will need a detailed drawing of the transformer bench, where all the components and the dimensions of each part are indicated. As for materials, benches are made of wood and metal. The best option is their combination. To improve strength, the frame of the transformer is made of metal, and the seats and tabletop are made of wood.

It is advisable to purchase pipes with a diameter of 20-25 mm with a galvanized coating. The protective layer will prevent the rapid development of rust.

From lumber you will need a planed board 20 mm thick. If the frame of the transformer is also made of wood, then use timber from larch, oak, or beech. You can take a pine board. It will last a long time on tabletops and bench seats.

To work, you still need a standard set of tools:

- wood hacksaw;

- plane;

- drill;

- screwdriver;

- roulette;

- hammer;

- pliers;

- screwdriver.

If the frame of the folding bench is metal, a welding machine is needed for assembly. A grinder will help you quickly cut a pipe.

Consumables you will need are bolts, screws, sandpaper, and welding electrodes.

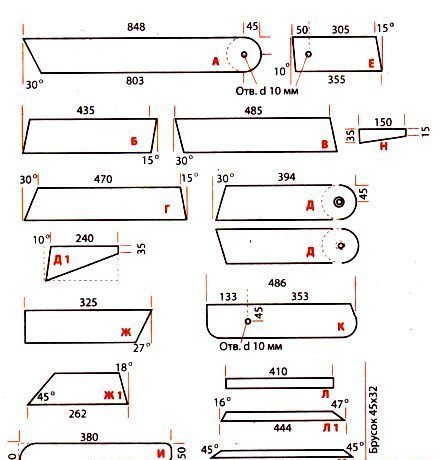

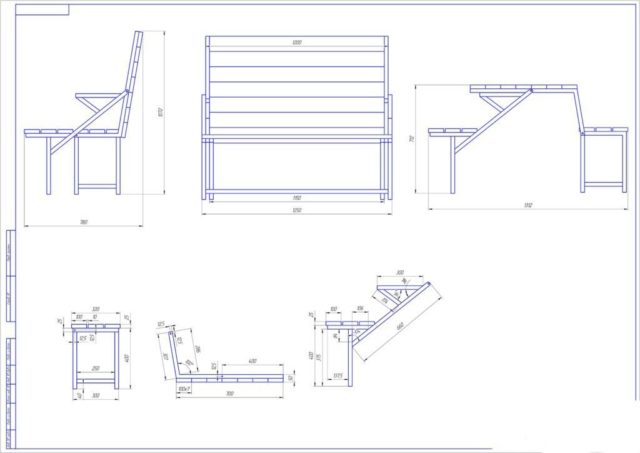

Drawings and diagrams for assembling a transforming bench

Without experience, it is not advisable to draw up a bench diagram yourself. It is optimal to find a ready-made drawing with the indicated dimensions of each part. If your neighbors have such a transformer, the circuit can be copied, but you need to carefully consider the design of the moving units. They create the main complexity of the design of a folding bench.

In general terms, different drawings of a transformer bench with a metal frame are similar. The sizes of a classic bench often differ. As a basis, you can take the drawing provided in the photo of all the wooden elements and the finished assembled structure itself.

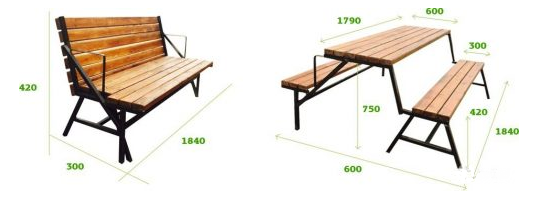

Dimensions of the transforming bench

The main purpose of a folding bench is to provide comfortable rest. The size of the structure plays an important role, since the number of seats on the transformer depends on it. Here, each owner is guided by his own needs. They take into account the composition of the family and the approximate number of guests coming.

Most often, in the classic version, the dimensions of a transformer bench made from corrugated pipe are as follows:

- height from ground to tabletop when unfolded – 750 mm;

- width of the unfolded transformer – 900-1000 mm;

- tabletop width – 600 mm, each seat – 300 mm.

The length of the transformer is a purely individual parameter. The number of seats depends on the size. However, benches are rarely made longer than 2 m.

How to make a transforming bench with your own hands

When the drawing and materials are prepared, they begin to create the structure. Each model of folding bench is assembled individually. It is important to understand that there is no general step-by-step instruction for making a transformer shop with your own hands. The assembly process for different benches can vary greatly.

The video shows an example of a bench:

The most successful model of a transforming bench

One rule applies to all transformers: the design must be simple, light, easy to unfold and fold. In this regard, the most successful model is considered to be a bench made from a profile with a cross-section of 20 mm.

The difficulty in manufacturing this transformer model is the need to bend the arcs. It will not be possible to neatly bend the profile of the house. For help, they turn to production, where there is a pipe bending machine. You will need to bend two semicircles for the legs and six arcs that form the support of the tabletop, and also simultaneously act as a folding mechanism for the bench.

The frames of the seats of the benches and the frame of the table are welded from straight sections of the profile. Sheathing is carried out with multi-layer moisture-resistant plywood and thick textolite.

In the video there is a do-it-yourself transformer bench in a visual demonstration:

A simple transforming metal bench

The simple design option is similarly based on the assembly of a metal frame.All elements of the bench are made of a smooth profile. They can be given a slightly curved shape without a pipe bender. To make a simple transformer look original, purchased forged elements are welded onto the frame. The table top is covered with plywood, and the seat of each bench can be made from two boards.

An example of a simple metal transformer is shown in the video

Folding transforming bench made of wood

Wooden transformers are often made according to one design. The process consists of the following steps:

- For the legs, eight identical blanks 700 mm long are sawn off from the timber. At the ends, oblique cuts are cut with a hacksaw or jigsaw. They will help you install the bench on a slope that provides it with optimal stability.

Important! Cuts on all workpieces must be made at exactly the same angle. - The frames for two transformer benches are assembled from edged boards. The lumber is sanded. 4 pieces 400 mm long and 4 pieces 1700 mm long are sawed off. The corners on the boards are cut off so that when joined, an oblong rectangular frame is obtained. One hole is drilled in long workpieces.

- To prevent the seats of the benches from sagging, the frames are reinforced with bars. The elements are mounted at a distance of 500 mm from each other, dividing the rectangle into sections. The prepared bars for the legs are fixed to the frame of the benches. They are installed at a distance of 100 mm from each corner. The legs of the transformer are fixed with three bolts. To prevent heads and nuts from protruding to the surface, they are hidden inside drilled countersunk holes.

- The next third frame is assembled for the table top, which, when the transformer is folded, acts as the back of the bench. Here, similarly, you will need timber. The frame is assembled into a rectangular shape measuring 700x1700 mm.It’s too early to do the sheathing at this stage. It will interfere with the assembly of the folding mechanism of the bench.

- When the frames of the benches and table are ready, they are placed on a flat area and connected into a single structure. In order for the transformer to fold, the connections are made with bolts. The nuts must be tightened to avoid spontaneous tightening or loosening.

- The structure is assembled from bars 400 mm long. It is attached between the bench and the tabletop in the corners. The elements should be located at the bottom of the tabletop, but to the side of the bench. Self-tapping screws are used to connect the workpieces.

- Two more pieces 1100 mm long are sawn off from the timber. The elements are secured with self-tapping screws in the center of another bench. Fasteners cannot be placed on the near side. It will not be possible to connect two benches with each other.

All finished transformer frames are combined into a single structure. The trim of the tabletop and bench seats is secured with self-tapping screws from edged polished boards. The structure is checked for functionality, and decorative finishing of the bench is performed.

Radius transforming bench

A radius-type bench forms a semicircular or circular seating area. The transformer frame is made from a profile. The pipes are given a radius bend. The benches are covered with planed boards. The blanks on one side are made wider than those on the opposite end. Thanks to the narrow side of the boards, it will be possible to achieve a smooth radial bend of the seat when attaching them to the frame.

The benches are made without a back, which allows them to be installed around a tree, a round table, or with the reverse side in the inner corner formed by the fence of the site, adjacent walls of neighboring buildings.

Transformable bench made from corrugated pipe

The most reliable is the classic folding bench made from a profile.The manufacturing principle is similar to a wooden structure, but there are some nuances. The photo shows a drawing of a transformer bench made from a square pipe, which will make it easier to assemble the structure.

The procedure for assembling a folding bench consists of the following steps:

- A profile pipe does not always come with a clean surface. Metal rusts when stored in a warehouse. During loading and unloading operations, mechanical shocks occur. Sharp jagged edges appear on the walls. All this needs to be cleaned off with a grinder and a sanding disc installed.

- According to the drawing, the profile is cut with a grinder into pieces of the required length. Each element is numbered and signed with chalk.

- The frame of the bench seat is welded from four blanks. If desired, the structure can be strengthened with a spacer, but then the weight of the transformer will increase, which is not very good.

- An L-shaped blank is welded for the back of the bench. Its long side simultaneously acts as a tabletop frame.

Advice! It is better to weld the L-shaped workpiece not at a right angle, so that the back of the bench is comfortable. - For the seat of the second bench, three pieces of profile pipe are welded. The result is a structure of indeterminate shape, as shown in the photo.

- All welded elements of the transformer frame are connected with bolts 60 mm long. Metal washers are placed under the heads and nuts. Do not forget to tighten, otherwise during operation of the moving units one nut will be tightened or unscrewed.

- The metal structure is sheathed with boards 20 mm thick. Fixation of wooden blanks is carried out with furniture bolts.

The disadvantage of metal bench legs is that they sink into the ground. The sharp edges of the metal scratch the paving slabs and push through the asphalt.To prevent this from happening, patches of plates measuring 50x50 mm are welded. It is best to round them, otherwise you can get hurt on the sharp corners. The finished transformer is sanded and painted.

Design of a folding transforming bench

It is optimal to install a folding bench under a canopy, otherwise the moving parts will begin to disappear over time due to exposure to natural factors. With this installation method, wooden elements are painted with stain and varnish. If the transformer will be standing in the garden without shelter in the summer, it is best to paint it with waterproof enamel for exterior use. The wood is painted annually and additionally impregnated with an antiseptic that protects against insects and fungi.

Before painting the metal frame, the weld seams are cleaned with a grinder. The structure is degreased, primed, and painted with enamel. A frame painted with a spray gun or spray paint looks more beautiful.

Conclusion

The drawings and dimensions of the transforming bench will help you create a workable folding structure. If the assembly technology was followed correctly, the product will last for many years and will not break on moving parts due to frequent use.