Content

The optimal material for building a doghouse is wood. However, edged boards are expensive, and it is not always possible to purchase them. Other available materials are not suitable for the kennel. How then to solve the problem of housing a pet dog? The solution to this situation is wooden pallets. They are also called pallets. These are wooden boards of a certain size on which products are transported in warehouses or stores. Pallets are discarded as they wear out. And they are precisely the free improvised material suitable for building a kennel. Now we will figure out how to quickly build a dog house from pallets and insulate it.

Where to start

So, making a dog kennel with your own hands begins with preparing the material. In our case, you will need to get at least five pallets. The shields themselves, as a ready-made structure for the walls of the booth, are not suitable. The pallet consists of timber, on which boards are filled on both sides with a small gap. To build a dog house, the pallets will need to be disassembled into building material. Only one shield is left untouched, which will be used entirely for making the bottom of the kennel.

The parts of disassembled pallets must be sorted immediately. The boards will be used to cover the dog kennel, and the frame of the house will be made from timber.

What size to make the booth

There are rules by which the dimensions of a dog house are calculated. The dog should feel free inside the kennel and be able to turn around. You can’t make a booth too spacious either. It will be cold in winter. You can determine the size of the house only by measuring the size of the dog.

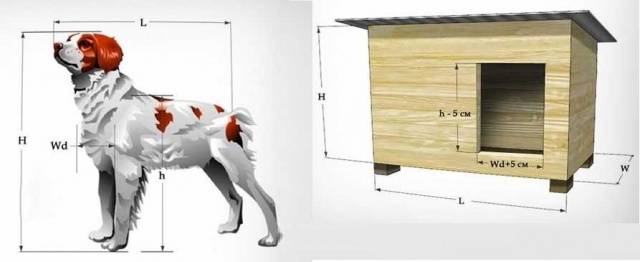

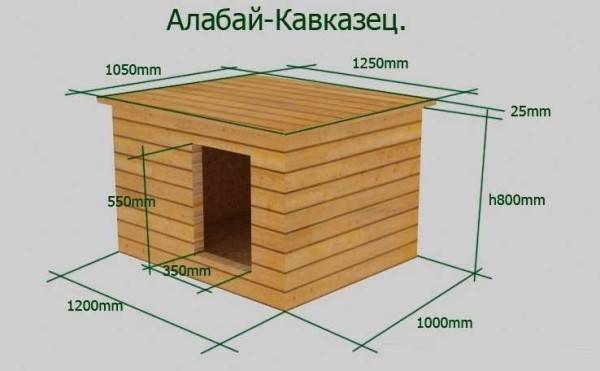

The photo shows a diagram indicating all the places where measurements need to be taken. The width and depth of the room are calculated based on the length of the dog. A lying dog is measured from the edge of the outstretched front paws to the end of the tail, and a margin of 15 cm is added. However, in our case, the bottom is a ready-made pallet with fixed dimensions. There are only two options here:

- If the dog’s dimensions greatly exceed the permissible dimensions, the pallet will have to be disassembled, and the bottom of the required dimensions will have to be folded from the blanks.

- When the dog’s measurements show slight deviations from the required dimensions or the dog is much smaller, the tray for the bottom of the kennel can be left in its original state.

Unlike the dimensions of the bottom, the height of the booth can be freely adjusted. After all, the walls will be assembled with your own hands from disassembled pallets into blanks. The height of the kennel can be determined by the height of the dog, which is measured at the withers. For a headroom, add 10 cm to the result obtained.

Calculate the size of the hole

The hole in the booth is not cut out just like that.Here you will need to make a few more measurements. The dog is a watchman. The dog must freely jump in and out of the kennel to perform its guard duties. The width of the hole is cut 5–8 cm larger than the width of the dog’s chest. Add 5 cm to the measurement at the withers to determine the height of the hole.

The hole on the booth can be cut into a rectangular or oval shape, but it is not located in the center of the front wall. It is better to make the entrance offset to one of the side walls, then the booth will have a blind corner. Here the dog can hide from the wind.

Winter kennel options include a partition inside the house with another hole. The booth consists of two compartments: a sleeping room and a vestibule. The idea is, of course, good, but it is not suitable for all dog breeds. Conscientious guards rarely visit the bedroom due to the fact that they cannot control their territory from there. Such dogs constantly lie in the vestibule, looking out of the hole, and the bedroom, in fact, remains unclaimed. When making a kennel from pallets with your own hands, it is still better to choose a one-room house with an offset opening.

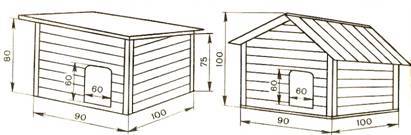

Deciding on the shape of the roof

The roof of the house can be made flat with one slope or a gable structure can be built. The second option is considered not very successful. The only advantage can be the increase in height due to the gable roof on a small booth. Building such a structure is much more difficult than a flat roof.With the onset of winter frosts, the extra space will make itself felt. It will be very cold in the booth, and all the heat will rise to the ridge of the roof and go out into the street through the cracks.

A pitched flat roof is easy to make. It can even be cut from a piece of OSB board, and covered with any roofing material on top. Another advantage of a flat roof is that the dog can lie on it. Many dogs like to lie down on the roof of the booth in the summer and watch their territory.

If, in terms of aesthetics, only a gable construction is acceptable, then it is advisable to nail a ceiling in the booth, separating the attic space from the living space.

Since we are talking about the roof, we need to dwell a little on making a canopy. Many dogs love to stand outside even in rain and snow. If you have excess building material and desire, you can install a small canopy over the booth. Then the dog will be able to walk freely in any weather, and in the summer he will hide from the sun.

Methods and materials used for insulating the booth

You can insulate a dog kennel with your own hands using any heat-insulating material. Mineral wool is ideal. Polystyrene foam is also not bad, but the dense material creates the effect of a thermos inside the house. If you close the hole with a curtain in winter, it will be difficult for the dog to breathe due to lack of fresh air. In this case, leave a gap or make a ventilation hole.

All structural elements must be insulated at once: walls, bottom and ceiling. You shouldn't use a lot of insulation. Nature has arranged it in such a way that dogs warm themselves well with their fur.A thick layer of insulation will create a sharp difference between the outside temperature and inside the house. For a dog, such a change in conditions is unacceptable.

Master class on making a booth from pallets

Now we will look at a step-by-step photo of how to make a dog house from old pallets. As you remember, we dismantled all the panels into blanks, only one pallet remained for the bottom. This is where we begin the construction of the kennel:

- Thanks to the pallet, we will have a booth on legs, and dampness and rainwater will not penetrate inside. We are making the house insulated, so we place a sheet of foam plastic 20 mm thick on a pallet, and fasten the OSB board on top with self-tapping screws.

- At the corners and center of the long sides of the pallet we nail racks made of timber with a section of 50x50 or 40x40 cm.

- From the same timber on top we knock down the frame trim. The roof will be attached to this frame in the future.

- The inside of the booth frame is covered with boards. The pallets used for work were old ones, so there may be a lot of chipped chips on them. To prevent the dog from getting hurt, we sand all the boards well with sandpaper.

- After attaching the inner lining to the outside of the box, the cells were formed. We lay foam plastic 20 mm thick here.

- We assemble a hole on the front wall from timber, after which we also insulate all the cells with foam plastic.

- Using a jigsaw, we cut out four rectangles from the OSB board according to the dimensions of the sides of the box, and from them we make the outer lining of the booth. On the front wall, where there should be a hole, we cut out a window in OSB using the same jigsaw.

- For a timber roof, we knock down a frame. We cover it from the inside with boards. We lay foam plastic in the cells, and attach an OSB board on top.It must be cut larger than the booth itself to form a visor.

- In the end you should end up with a dog house like this.

In the video, a dog house made from construction waste:

The walls and roof made from OSB boards are resistant to moisture, but it is better to paint them. For reliability, you can lay a rigid roofing covering.