Content

Before building a wooden pool, it is recommended to study the features of existing structures and placement options on the site. After this, it is necessary to draw up a work plan taking into account the requirements of fire and electrical safety standards and compliance with sanitary standards.

Features of building a wooden pool

Having decided to get a swimming pool, summer residents pay attention to wooden structures. In addition to the availability and manufacturability of the wooden material, which makes it easy to process it with minimal skills, gardeners are attracted by the possibility of the pool harmoniously fitting into any terrain.

The advantages include the low cost and high speed of constructing an object made of wood, at a cost of about 7–15 thousand rubles. A stylish and functional wooden pool can be made on your own in just 1-2 days.The design is distinguished not only by its popularity, but also by the features of its use - the liquid required for the pool should not pose a danger to the user.

When building a wooden pool from slats and beams, experts recommend taking into account characteristic features, including:

- To ensure the drainage of used water by gravity when planning the construction of a wooden pool, it is better to choose a site that has a certain slope.

- To prevent the passage of water into the inner layers of the soil and to support the weight of the structure without deformation, it is better to choose clay soil with high strength values for the construction of the building.

- The correct choice of the optimal depth of a wooden pool, the figure should not exceed 150 cm from the bottom to the surface of the water for adults and no more than 50 cm for children.

Important! When building a wooden pool, the bottom surface can be formed from several levels (for children and adults), fencing off the area designated for swimming for children with a net. - To prevent dirt and dust from getting into the water, as well as protection from the prevailing winds, it is recommended to take into account the direction, choose the right shape of the bowl and place the wooden structure on the side of the building, protecting it from the action of air flows. If a rectangular container shape is chosen, experts recommend placing the long side of the building in the direction of wind movement.

- Since a feature of any pool that makes it possible to distinguish it from just containers with water is the organization of periodic changes of liquid, at the construction stage it is necessary to think about how the wooden pool will be filled.

- To ensure cleaning of a wooden pool after its long-term use, it is recommended to install pumps.

The bowl of a wooden building is made using polymer film, and the frame is made of durable, strong boards. Before building a homemade pool from boards, builders recommend developing a design for the structure indicating the shape, overall dimensions, depth of the pool, cleaning features and supply of communications to it.

Among the most common schemes for organizing water supply, experts call the use of stationary pipelines and a long hose to fill the bowl.

It is advisable to arrange holes for overflows in the far corner, as a result of which, when exposed to wind, debris located on the surface of the liquid will flow into the drainage on its own.

Pros and cons of wooden frame pools

Given the growing popularity of wooden pools in summer cottages and local areas, many owners are thinking about building such structures. When choosing from a variety of options, they tend to use wood due to its obvious advantages, which include:

- no need to attract qualified specialists for the construction of a wooden building;

- affordable cost of basic materials;

- environmental friendliness of raw materials;

- the ability to fit wooden structures into any natural landscape;

- ease of organizing the replacement of liquid, which can be used to water plants and trees on the site;

- there is no need to dismantle the wooden pool for the winter.

However, in addition to the advantages, when choosing the location of the building, one should also take into account the disadvantages of wooden structures, among which are the following:

- Possibility of damage by rodents if the wooden pool is located near the storage room and other household objects. It is possible to prevent damage by equipping the structure with repellent devices or applying a toxic composition against rodents.

- If the building is located close to trees (to protect it from the sun's rays), there is a high probability of damage to the structure by a fallen branch or root system.

- The need to frequently clean a wooden pool and change the water occurs when falling leaves enter the pool, causing the development of bacteria and the appearance of algae.

- Shorter service life of a wooden structure compared to concrete structures.

Types of wooden pools

Among the well-known types of wooden pools, the following should be highlighted:

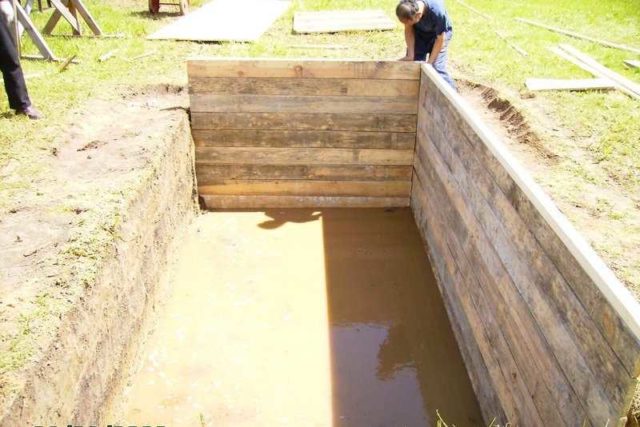

- A partially in-ground wooden pool is a structure that is 50-60% submerged below ground level. Such buildings have a number of advantages, which include the ability to harmoniously fit into any landscape and the ease of use of a wooden pool.However, the construction is a more expensive and labor-intensive procedure compared to the surface option.

- Surface structures, the production and installation of which does not involve the extraction of soil. The height of such wooden structures usually does not exceed 1.5 m, since if this figure is exceeded, the pressure exerted by the column of liquid on the walls of the bowl can lead to their destruction. In addition, in this situation, it will be necessary to purchase or manufacture a high ladder to provide entry to and exit from the wooden pool.

- Recessed buildings provide for the arrangement of a wooden pool below ground level. Such work is carried out using excavators and requires the installation of pumps and the organization of a power supply system.

The frame pool covered with wood, shown in the photo below, can be designed in the form of a complex polygon, triangle, rectangle, square, circle or have any other shape. However, when designing, it should be taken into account that to ensure the stability of round-shaped wooden structures, you will have to resort to the services of a qualified carpenter, which will increase the cost of construction. The choice between a panel frame and a base made of separately knocked down boards will largely depend on the budget and access to building materials.

Required tools and materials

According to experts, the construction of a swimming pool with a wooden frame, subject to preliminary preparation of the site for construction, takes about a day.However, in order to quickly erect a structure, you must first stock up on tools and materials.

To translate the developed project into reality, you need to ensure that you have:

- roulette;

- bayonet shovel;

- hammer;

- screwdriver;

- circular saw or hacksaw for wood;

- pencil, marker;

- scribers;

- water level;

- construction hair dryer;

- wood screws.

In addition to the listed tools, in order to make a pool from boards, you need to purchase the following materials:

- sand;

- crushed stone;

- cement;

- edged board 100×50 mm;

- antiseptic;

- wooden beam measuring 10×5 or 10×10 cm;

- PVC flooring or polyethylene film;

- tarpaulin.

In addition, it is recommended, and in some wooden (and not only) structures, mandatory, to install a pump to remove used liquid. For this purpose, it is necessary to buy a self-priming centrifugal pump of low power and lay electrical wiring at the stage of organizing the foundation of a wooden structure. Experts recommend installing a filter that allows you to separate organic debris and sediment, this will increase the period between fluid changes in a wooden pool.

How to make a wooden pool with your own hands

Since it is considered the most economical to make a pool yourself, it is worth getting acquainted with step-by-step instructions on how to make a wooden pool with your own hands. Before starting work, it is necessary to clean the area where construction will be carried out, mow the grass on it, and mark the area in accordance with the developed project. A pit is dug inside the marked area using a bayonet shovel.

At this stage, the necessary communications are installed, for example, the laying of water supply polyethylene, polypropylene or metal pipes, the depth of which should be below the freezing level of the soil in the region.

The bottom surface of a wooden pool is formed in such a way that a slight slope is formed towards the center of the structure, in which a drainage pit measuring 50x50 cm or larger and a depth of 0.2-0.3 m is made. The dug pit is filled with gravel, which is used to speed up the drainage of liquid . You can also equip a sewer pipe leading into a drainage receptacle. The remaining space of the prepared site is filled with gravel to a depth of 0.2 m, after which it is covered with sand and compacted by mechanical or manual compaction. In some cases, wooden panels made from edged boards in the shape of the outline of the future wooden pool can serve as the base for the pool.

The implementation of a wooden pool will create a ventilated bottom, which will prevent the appearance of moisture and the associated development of fungal microflora.

DIY pool frame made of wood

Experts note that the most common and easiest to implement is the construction of a wooden structure with a rectangular shape. It is necessary to consider the sequence of actions for the implementation of a project for such a structure.

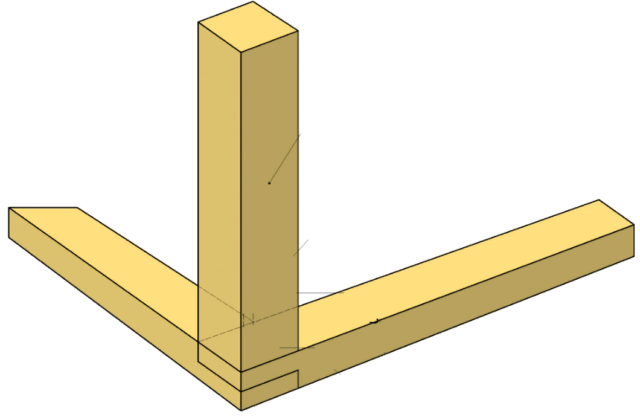

In order to build a wooden pool at your dacha with your own hands, you need to:

- At the corner points of the structure, observing the correct geometry, checking the dimensions of the sides and diagonals, drive in pegs.

- Prepare racks from timber, for which you need to cut 4 pieces of wood, the height should be equal to the depth of the wooden pool, to which you should add 0.5 m necessary for installing the products in the ground.

- Clean the prepared workpieces and coat them with an antiseptic to prevent rotting under the influence of moisture.

- Treat the part of the timber that is buried in the ground using bitumen mastic and wrap the workpiece in roofing felt.

- Checking the position according to the building level, lower the posts into the sockets and fill them with sand and crushed stone.

- Compact a piece of earth around the installed racks, check the compliance of the dimensions along the length and diagonals.

- At the bottom and top of each side it is necessary to tighten ropes, which will serve as a guide when installing the remaining racks. They are installed along the entire perimeter every 1-1.2 m of the structure.

To make spacers, you need to drive a peg at a distance of 0.5-0.6 m from each post, then rest a piece of board measuring 10x5 cm against it, nailing it to the support from above and attach a jumper to form a triangle.

An alternative design may involve fastening metal-wood structures, which act as supporting elements, to a prepared concrete site. After this, a cladding of wooden elements with grooves is installed between the installed supports, while the outer parts of the products are attached to the supports by their protruding sections using screws.

Finishing a frame pool with wood

At the next stage of construction, the pool is finished with wood and the interior of the pool is lined to ensure liquid retention. This procedure also includes a number of sequential operations, including:

- Cutting prepared horizontal boards treated with antiseptics into blanks having the dimensions indicated in the sketch.

- When installing slats with a thickness of over 2.5 cm, the procedure can be carried out close to the surface of the previous element or with a gap of 10-20 mm.

- Fixing the installed boards is done using self-tapping screws.

- Laying of polyethylene film is carried out after completion of the sheathing. This procedure is carried out overlapping with a supply of material in the area of the edges of about 15-20 cm and excluding its slipping inward.

- Carrying out markings to indicate areas where it will be necessary to ensure a tight fit of the product to the corners. In some cases, it is enough to turn the film over.

- Checking the fit of the product on all sides and the bottom of the structure, fixing areas containing cuffs.

- Treatment with the help of a construction hairdryer of the entire surface of a pool made of boards, made by hand, during which the film is heated, which ensures its attachment to the base and side surfaces of the structure. After heating with a hairdryer, the surface is rolled using a rubber construction roller.

After this, the film joints are connected along the edge of the product with a construction hairdryer equipped with a nozzle with a small diameter.

Operation and maintenance of a wooden pool

To successfully use a wooden pool, experts recommend carefully and thoroughly removing all debris from the structure after completion of construction. This is due to the fact that the presence of any fragment with sharp parts can damage the film, resulting in the need to replace the entire layer.

Before starting operation, it is recommended to test a wooden pool, during which on the first day the pool is filled to 1/3, monitoring the liquid level throughout the day. If no liquid leaks or drop in level are detected, the wooden pool can be completely filled. When filled, monitor the liquid level for 5-7 days. If it remains constant or has minor changes, the wooden pool is considered suitable for use.

In order to prevent the development of pathogenic microflora during the use of a wooden pool, it is recommended to add copper sulfate. The approximate ratio of this substance is 2 tsp per 2500 liters of liquid.

To ensure safety when there are small children in the house and to increase the period between cleanings of a wooden pool, it is recommended to provide additional material (for example, a tarpaulin).

Tips and tricks

If you have a choice between buying and making a wooden pool with your own hands, done at the dacha, experts recommend preferring the second option.Firstly, with this approach it becomes possible to build a pool of any type, size and shape. Secondly, by making the structure yourself you can save a lot. Its construction takes no more than 1-2 days. The cost of a wooden structure for a swimming pool, made at home, is approximately 7-15 thousand rubles. At the same time, for the simplest rectangular wooden structure, consisting of a frame and film, the buyer will have to pay about 75 thousand rubles, and for a product with an octagonal shape, about 145 thousand.

Construction experts give some recommendations regarding the technology of making a wooden pool, among which are the following tips:

- You can use paving slabs as a foundation or dig a small pit 100 mm deep. After preparing the area, it is necessary to fill it with cement and wait until the material hardens completely, after which, having laid the substrate, they begin to build the pool itself.

- When using unedged boards, a mandatory step is to clean the surface from bark, strip it and treat it with antiseptics or agents that prevent damage by insects, for example, drying oil or wax.

- After completing the construction of the frame, it is recommended to create steps to make it easier to enter or exit the pool.

- When attaching a film or awning to the surface of the frame, it is necessary to avoid tension and the formation of folds, which leads to disruption of the shape and failure of the product.

To improve the appearance of the boards used in the construction of a wooden pool, giving them a stylish and attractive look, experts recommend that after cutting the workpiece to size between the supports, treat the surface of the lumber with sandpaper and cover it with a layer of stain.

Conclusion

A wooden pool in a country house has a number of advantages over structures made from other materials. Before its construction, it is necessary to select the shape, dimensions, location of the building and develop a design for the structure. By following the step-by-step technology described, a wooden object can be erected within 1-2 days, while the costs of the summer resident will be 10-15 times lower compared to ordering and installing the finished product.