Content

Large equipment is inconvenient for processing small gardens, so those that appeared on sale mini tractor immediately began to be in wide demand. In order for the unit to perform its tasks, it requires attachments. The main tool for cultivating the land is a plow for a mini-tractor, which, according to the principle of operation, is divided into three types.

Mini tractor plows

There are many types of plows. Based on their operating principle, they can be divided into three groups.

Disk

From the name of the equipment it is already clear that the design has a cutting part in the form of disks. It is intended for processing heavy soil, swampy soil, and virgin soil. The cutting discs rotate on bearings during operation, so they can easily cut even a large number of roots in the ground.

As an example, consider the 1LYQ-422 model. The equipment drives the power take-off shaft of a mini-tractor, rotating at a speed of 540–720 rpm. The plow is characterized by a plowing width of 88 cm and a depth of up to 24 cm. The frame is equipped with four discs. If, while plowing the ground, the cutting element hits a stone, it does not deform, but simply rolls over the obstacle.

Ploughshare-dump

In another way, this equipment is called a reversible plow for a mini-tractor due to the principle of operation. After finishing cutting the furrow, the operator deploys not the mini-tractor, but the plow. This is where the name came from. However, according to the design of the cutting part, it will be true when the plow is called a plowshare-moldboard. It comes in single and double hulls. The working element here is a wedge-shaped ploughshare. As it moves, it cuts the soil, turns it over and crushes it. The plowing depth of single- and double-furrow plows is adjusted by the support wheel.

As an example of a double-furrow plow for a mini-tractor, let's take the R-101 model. The equipment weighs about 92 kg. You can use a 2-body plow if the mini-tractor has a rear linkage. Using the support wheel, the plowing depth is adjusted. For this 2-case model it is 20–25 cm.

Rotary

A modern but complex design for a mini-tractor is a rotary plow, consisting of a set of working elements mounted on a movable shaft. The equipment is characterized by ease of use. When cultivating the soil, the operator does not have to drive the tractor straight along the line. Rotary-type equipment is usually used when preparing soil for planting root crops.

Depending on the rotor design, the rotary plow is divided into 4 types:

- Drum-type models are equipped with rigid or spring pushers. There are also combined designs.

- Blade models are a rotating disk. 1 or 2 pairs of blades are attached to it.

- Blade models differ only in the working element.Instead of blades, the rotating rotor has blades.

- The screw model is equipped with a working screw. It can be single- or multi-pass.

The advantage of rotary equipment is the ability to loosen soil of any thickness to the required degree. The impact on the soil is from top to bottom. This makes it possible to use a rotary plow with a low traction force of a mini-tractor.

Of all the types considered, the most popular is the 2-hull reversible plow. It consists of several frames on which tools of different purposes can be attached. Such equipment can have two functions. Let’s say that while plowing the soil, harrowing also occurs at the same time. However, a homemade plow for a mini-tractor is easier to make than a single-body plow, but it is less efficient.

Self-production of a single-furrow plow

It is difficult for an inexperienced person to make a 2-body plow for a mini-tractor. It is better to practice on a single-hull design. The hardest job here will be bending the blade. In production this is done on machines, but at home you will have to use a vice, hammer and anvil.

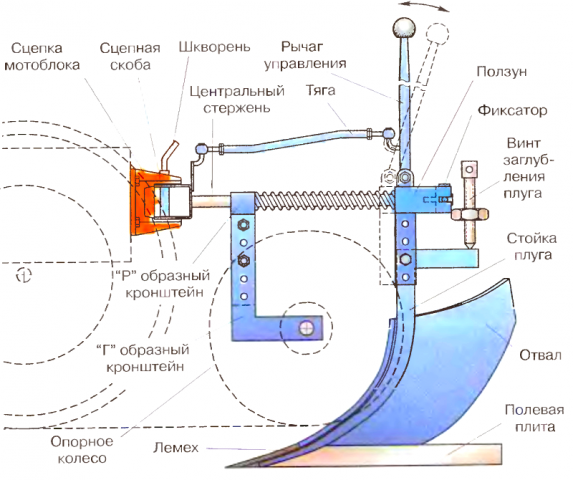

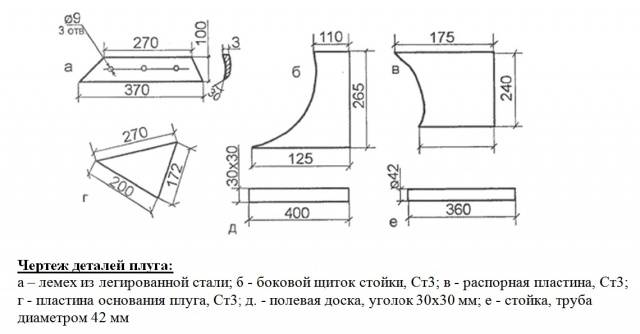

In the photo we presented the diagram. It is used to manufacture a single-hull type structure.

To assemble a plow for a mini-tractor with your own hands, perform the following steps:

- To make a blade you will need sheet steel 3–5 mm thick. First, the blanks are marked on the sheet. All fragments are cut out with a grinder. Next, the workpiece is given a curved shape by holding it in a vice. If an area needs to be corrected somewhere, this is done with a hammer on an anvil.

- The lower side of the blade is reinforced with an additional steel strip. It is fixed with rivets so that their heads do not protrude on the working surface.

- The finished blade is attached to the holder from the back. It is made from a steel strip 400 mm long and 10 mm thick. To adjust the plowing depth, 4–5 holes are drilled on the holder at different levels.

- The body of the attachment is made of steel pipe with a diameter of at least 50 mm. Its length can be in the range of 0.5–1 m. It all depends on the method of attachment to the mini-tractor. On one side of the body, a working part is installed - a blade, and on the other side a flange is welded. It is needed to couple the plow with the mini-tractor.

If desired, the single-hull model can be improved. To do this, install two wheels on the sides, adhering to the center line. The diameter of the large wheel is selected individually. It is installed according to the width of the blade. A small wheel with a diameter of 200 mm is placed on the reverse side along the center line.

The video talks about making a plow:

Independent production of attachments, taking into account the purchase of metal, will not cost much less than purchasing a factory design. Here it is worth thinking about what is easier to do.