Content

A mini-tractor is a very necessary equipment on the farm and in production. However, without attachments, the efficiency of the unit is reduced to zero. You can only move with this type of equipment. Most often, factory-made attachments for mini-tractors are used, but home-made designs are also found.

General overview of factory-made equipment

Mini tractors They work in all industries, but most of all they are in demand in agriculture. The manufacturer takes this into account, so most attachment mechanisms are designed for soil treatment, caring for animals and vegetation, as well as performing planting and harvesting work. To connect most equipment, a three-point hitch is installed on a mini-tractor, but there is also a two-point option.

Equipment for preparing soil for planting work

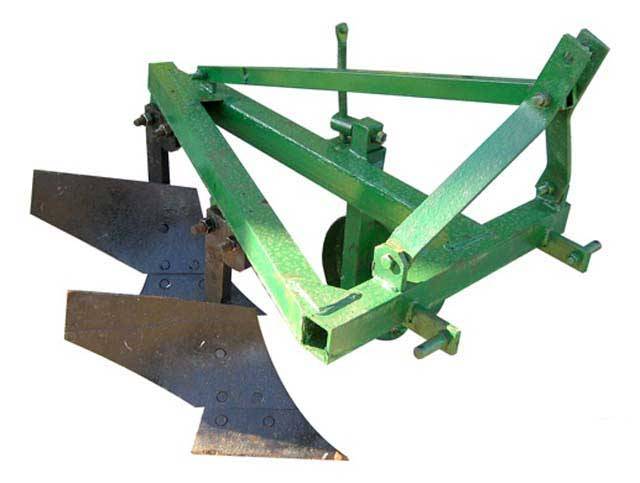

The plow is responsible for preparing the soil. A mini-tractor operates with attachments of various designs.One- and double furrow plows used with equipment with a power of up to 30 hp. With. Their plowing depth is adjustable from 20 to 25 cm. If the unit is equipped with a motor of more than 35 liters. pp., then you can hook up a four-furrow plow, for example, model 1L-420. The plowing depth has already increased to 27 cm. Such models are called reversible or plowshare-moldboard and are most often used by private owners for their summer cottages.

There are also disc plows used for heavy soils and virgin lands. On farms, soil preparation can be carried out using rotary models.

Before planting, the soil needs to be prepared. Disc harrows are responsible for this area of work. Depending on the design, their weight is in the range of 200–650 kg, and the soil working width is from 1 to 2.7 m. Different models differ in the number of discs, as well as the harrowing depth. For example, 1BQX 1.1 or BT-4 cultivate soil up to 15 cm deep.

Planting equipment

This type of trailed mechanism includes potato planters. There are single- and double-row models with different tank volumes for planting tubers. The potato planter itself cuts a furrow, throws the potatoes at an equal distance, and then rake them in with soil. All this is done while the mini-tractor is moving across the field. As an example, we can take the UB-2 and DtZ-2.1 models. The planters are suitable for domestic and Japanese equipment with a power of 24 hp or more. With. The equipment weighs around 180 kg.

Plant maintenance equipment

For tedding and raking hay into windrows, a rake is attached to the mini-tractor. Such equipment is more in demand by farmers and private owners who have large areas allocated for haymaking. Tedding rakes are produced in various modifications. For a mini-tractor with a power of 12 hp or more. model 9 GL or 3. 1G is suitable. The equipment is characterized by a swath width of 1.4–3.1 m and a weight of 22 to 60 kg.

Cultivators clear the field of weeds, loosen the soil, and remove the roots of unnecessary vegetation. The equipment is used after the plantings emerge and during the entire period of their growth. Common models include KU-3-70 and KU-3.0.

Mounted sprayers help control crop pests in fields and gardens. Models SW-300 and SW-800, produced by a Polish manufacturer, are universal. The equipment is suitable for all models of mini-tractors. With a liquid solution flow rate of 120 l/min, the jet covers up to 14 m of the treated area.

Harvest equipment

This type of equipment includes potato diggers. Conveyor and vibration models are mainly used. For a homemade mini-tractor, the diggers are often made independently. The easiest to manufacture is the fan design. There are also drum-type and horse-mounted diggers. Factory-made models include DtZ-1 and WB-235. Any potato digger is connected to the rear linkage of the tractor.

Other types of factory-made equipment

This category includes mechanisms that are rarely used in the agricultural industry. Most often they are in demand at construction sites, as well as by public utilities.

The blade is connected to the front linkage of the tractor.It is needed to level the soil and clear the area of debris and snow. When cleaning roads, the blade is usually used in conjunction with a rotary brush attached to the rear linkage of a mini tractor.

A bucket is a kind of mounted excavator on a mini-tractor, which is designed to perform earth-moving work. A small bucket is convenient for digging trenches for laying communications or small pits. The mounted excavator has its own hydraulic distributor. To connect to a mini-tractor you need a three-point hitch.

A front-end loader, or KUN in other words, is often used in warehouses and granaries. From the name it is already clear that the mechanism was created to perform loading operations. To prevent a light tractor from overturning under the weight of a loaded KUN, a counterweight is attached to the rear linkage.

The price of factory-made equipment is quite high. It all depends on the manufacturer, model and other factors. Let’s say the cost of a plow varies from 2.4 to 36 thousand rubles. A harrow will cost from 16 to 60 thousand rubles, and potato planters from 15 to 32 thousand rubles. Such high cost encourages enterprising private owners to make the necessary devices with their own hands. The easiest way is to make a homemade hitch, which we will talk about now.

Types of attachments and independent production of a three-point structure

A do-it-yourself attachment for a mini-tractor is made from a steel profile by welding. But before you do this, you need to understand the essence of the design. The hitch is needed to connect the working equipment of the tractor. There are models of seeders and mowers for which the linkage ensures transmission of motor power.

The three-point hitch is made movable in two planes: vertically and horizontally. The hydraulic drive is usually installed only on the front linkage. Now let's talk about the design. Almost all agricultural equipment is connected to a three-point hitch. An exception may be a mini-tractor with caterpillar tracks or with a broken frame. Such equipment can have a universal hitch, which, when working with a plow, transforms and becomes a two-point one.

The three-point homemade hitch is a triangle welded from a steel profile. The mobility of the connection with the tractor is ensured by a central screw. An example of a homemade hitch can be seen in the photo.

Self-production of attachments

Craftsmen make most of the attachments for gardening themselves. These are mainly potato planters and diggers. It is more difficult to make a plow, since you need to bend the ploughshare at the right angle.

It’s easier to cook KUHN yourself. For the bucket, sheet steel 6 mm thick is used. The loader is attached to racks made of steel pipe 100 mm thick. Rods for connecting to hydraulics are made from pipes with a diameter of 50 mm.

The blade is considered very easy to manufacture. It can be cut from a steel pipe with a minimum cross-sectional radius of 70 cm. It is advisable to take a metal thickness of at least 8 mm, otherwise the blade will bend under load. To connect the equipment to the hitch, an A-shaped structure is welded. It can be strengthened with longitudinal elements.

The video shows ideas for making a potato planter:

When making any design yourself, you need to not overdo it with dimensions.Otherwise, it will be difficult for the mini-tractor to lift a heavy KUN or drag a planter with a large amount of potatoes in the bunker.