Content

Every beekeeper needs a wax melter, regardless of the number of hives available. The device can be purchased factory-made or you can construct a primitive but effective design with your own hands.

What is a “wax grinder”, its purpose in beekeeping

Beeswax is considered a useful beekeeping product. It is used for medicinal purposes and cosmetology. Candles are cast from wax, used in some branches of the food industry, and new foundation is made. To obtain it yourself, in your home apiary and on an industrial scale, wax melters are used.

What are wax melters for?

A factory or homemade wax melter is designed for one purpose - melting wax.The bee product has the property of melting according to the principle of paraffin when exposed to temperatures from + 70 OC. A wax melter is a container in which used honeycombs are melted. The resulting wax in a liquid state is filtered, poured into molds, and left to harden.

Types of devices

To make a wax melter at home, you need to know about the existing types of devices and choose the best option for yourself. Common to all designs is a tank for loading and melting wax. The energy sources used to heat the bee product differ. Hence, each type of wax melter has its own design features. The following models for burning wax are popular among beekeepers:

- solar powered device;

- steam plant;

- centrifugal machine;

- electric model.

Any beekeeper can assemble each device for melting wax with his own hands.

The principle of operation of the wax refiner

Regardless of the design and energy used, the operating principle of any wax melter is the same. Honeycombs loaded into the tank are heated to temperatures above + 70 OC. The combustion process begins. Solid wax turns into a liquid state and is then used for its intended purpose.

Frame wax melter

A special feature of the frame wax melter is the ease of use of the device. You can melt the wax directly from the frames with your own hands, without cutting out the honeycombs with a knife. For a small apiary, a steam wax melter with 6 frames, made in the form of a rectangular box, is considered a good option. If there are a lot of hives, they assemble a large structure with 24 frames with their own hands. The golden mean is considered to be a wax melter that can hold 12 frames.In addition to steam, solar energy or electricity can be used to melt wax.

Advantages of the frame model:

- a high temperature is maintained inside the container between the frames to ensure uniform melting of all the honeycombs at once;

- simple device;

- there is no need to cut out the honeycombs, since they are loaded into the tank along with the frames.

Minuses:

- the beekeeper must constantly monitor the temperature inside the tank while heating the wax;

- When using steam or electricity, the flammability of the wax melter increases.

The frame model for melting wax is characterized by its simple design. The first version of the wax melter is based on the use of the energy of an open fire (bonfire). First, they weld a metal box with their own hands - the main body. A layer of sand is poured onto the bottom to prevent the bottom from burning out. A sealed metal tank with water is installed inside the box, and another box made of mesh or rods is immersed inside this container for installing frames.

To operate, the wax melter is placed on a brick. A fire is lit under the building. Frames are installed in the box and the device is covered with a lid. When the temperature inside the housing rises, the molten wax will begin to flow into the water and settle to the bottom of the container, where it will simultaneously be filtered from foreign impurities.

When all the frames are melted, they are removed from the box. The container with water is removed from the body, and after cooling, the frozen clean wax is selected. Wash the device with your own hands in a warm state. Cold residues of stuck wax are difficult to clean off.

The second version of the frame wax melter is even easier to assemble with your own hands.You only need one box of water and a box for loading frames. The lid is made of glass. The wax melter loaded with frames is placed in the sun. Through the glass lid, the honeycombs will begin to melt when heated by the sun's rays, and the wax will flow into the water.

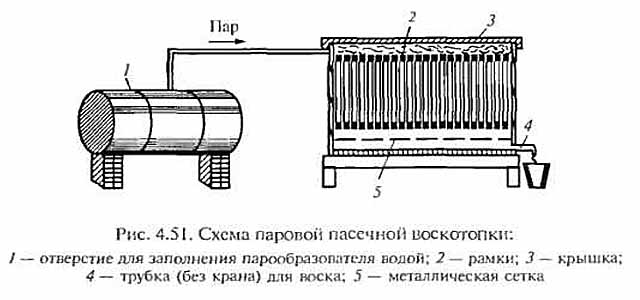

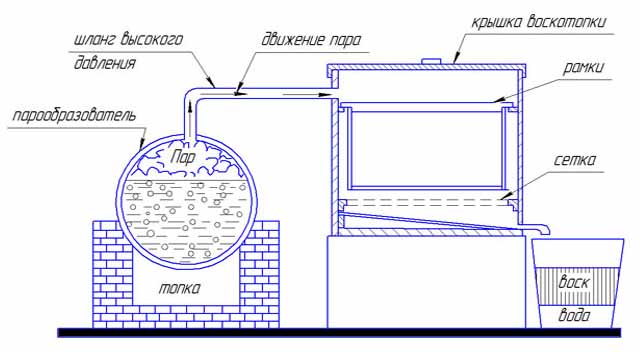

The third version of the frame wax melter is the most complex, but effective. The melting of the wax occurs in a gentle way from exposure to hot steam. Steam wax furnaces from Granovsky, which are popular among beekeepers, work on this principle. To make a homemade product, you first need to build a steam generator with your own hands. Water will boil in a hermetically sealed container, and steam will be directed through a pipe with a hose inside the wax furnace, where the frames are installed. The steam generator itself can be heated over a fire or gas stove.

Steam wax melter

Frame-type steam wax melters are most often found on sale. The popularity of factory-made products for wax remelting is due to a number of advantages:

- standard dimensions;

- comfortable, thoughtful design;

- rapid melting of honeycombs;

- obtaining high-quality unburnt wax;

- The wax melting process occurs with minimal intervention from the beekeeper.

A do-it-yourself wax melter assembled at home does not ensure complete automation of the process. The beekeeper needs to monitor the maintenance of the optimal temperature.

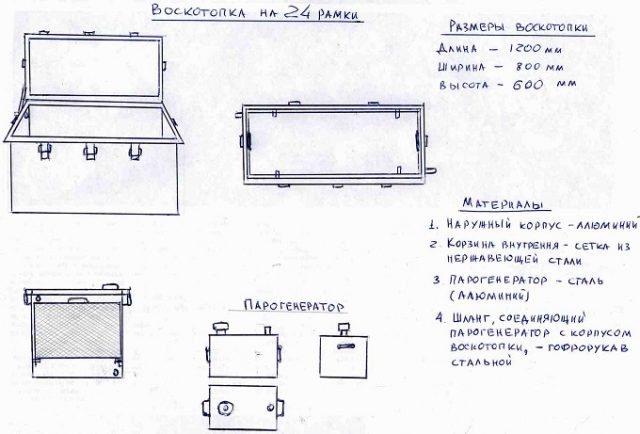

Do-it-yourself steam wax melter: drawings, tools and materials

To assemble it yourself, you will need drawings with exact dimensions or, as a last resort, a diagram of a steam wax furnace. The structure can be assembled according to your individual calculations. The steam unit for heating wax consists of 4 main units:

- sealed housing with lid;

- lattice basket for fixing frames;

- steam generator;

- container for storing liquid wax.

To construct a wax melter you will need sheet steel. Galvanized and aluminum work well. Stainless steel is considered the best option, but is more expensive. The frame basket is made of mesh or rods.

It is optimal to equip a homemade wax melter with your own hands according to the principle of a factory analogue with taps for draining melted wax. The steam generator is connected to the body of the wax furnace using a flexible hose. It should be durable with reinforced braid. It is important to install a tap that regulates the water supply. If the liquid boils away, the container may burn out.

The tools you will need are a grinder, an electric drill, a welding machine, a hammer, and pliers.

Do-it-yourself steam generator for wax refinery: drawings

The energy source of the wax furnace is a steam generator. The complex name hides a sealed container with durable metal walls. A simple do-it-yourself steam generator for wax refinery is made from a milk can or gas cylinder. The first option is more convenient due to the presence of a ready-made lid with a lock. It is convenient to pour water through the wide neck. The upper part of the steam generator is equipped with a fitting for connecting a high pressure hose.

How to make a steam wax melter with your own hands

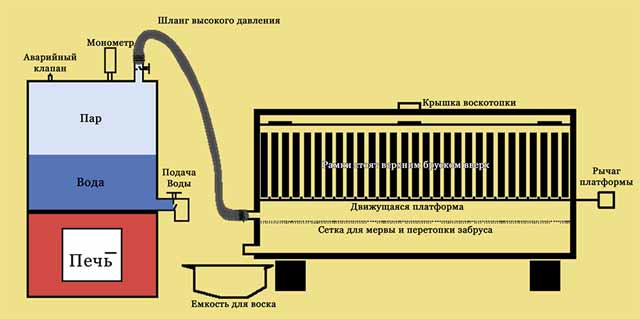

When the steam generator is ready, you can adapt it yourself to fit a potbelly stove. The water in the cylinder can be heated using a fire, placing it on brick stands.A more advanced option involves inserting an electric heating element connected to a thermostat into a cylinder with your own hands. A high-pressure hose is removed from the outlet fitting and connected to the fitting on the body of the wax melter.

The steam wax melter itself is assembled with your own hands at home from a metal case with a closing lid. A tray is placed at the bottom and a tap is removed from it to drain the melted wax. A filter mesh is installed above, which will separate the merva from the wax. The frames are placed above the filter, using fasteners or a mesh basket.

An important stage of work is to arrange the heating of the steam generator for the wax furnace with your own hands. The simplest design involves the use of a modified gas cylinder adapted for a potbelly stove.

How to use a steam wax melter

Heating wax with your own hands begins by filling the steam generator with water to half the capacity. There is free space above the liquid for vaporization. Frames are installed inside the basket of the wax melting device. In the steam generator, they begin to heat the water with fire or a heating element, which depends on the chosen design. As the water begins to boil, steam will begin to accumulate in the steam generator and flow through the hose into the wax furnace. When exposed to high temperatures, the honeycomb will begin to melt. Liquid wax flows through the filter mesh, accumulates on the tray and flows through the drain valve into the prepared container.

The video shows in detail the wax melting process:

Solar wax refiner

The simplest device for melting beekeeping products is based on the use of solar energy. The design is a box covered with glass on top.The frame is fixed inside at an angle. The sun's rays pass through the glass, heating the honeycomb to a temperature of + 70 OC. There is a grid under the frame. Molten wax is filtered through it and flows into the pan.

A glosser wax melter works more efficiently, based on a similar principle, but with the addition of elements of a device for processing photographs. Mirror sheets are taken from an old photo gloss and fixed to the inner walls of the wax furnace. Reflectors will reflect the sun's rays from the walls, directing them to the frame. You can insert the photoglosser itself inside the body of the device for melting wax, as an auxiliary source of heating from electricity.

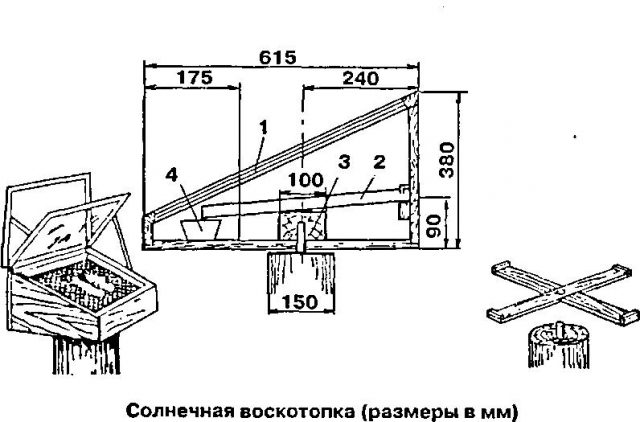

DIY solar wax melter: drawings, tools and materials

The materials for making the wax melting box will need plywood or chipboard, wooden slats. The role of the lid will be played by window glass. For safety, it is framed with a wooden frame. A metal tray made of aluminum or stainless steel is installed at the bottom of the box. You also need a fine mesh mesh to filter the wax.

The tools you need to have are a wood saw, a jigsaw, a screwdriver, pliers and a hammer. The elements of the box are tightened with self-tapping screws. The opening lid is equipped with hinges.

How to make a solar wax grinder

Do-it-yourself assembly begins by cutting out blanks for the box according to the drawing. The elements are connected with self-tapping screws. Stoppers are installed inside from slats, onto which the frame will be placed at an angle. A metal tray is installed at the bottom - a wax collection, and a filter mesh is placed on top. The glass sheet is framed with a frame of slats and secured to the body with hinges.At this stage, we can assume that the solar wax melter has been made with your own hands at home. All that remains is to install it in the sun, lay the frame, and wait for the result.

Electric wax grinder

From the name of the device it is clear that the source of energy for melting wax is electricity. Most often, such designs are made in combination. By covering the tank with a glass lid, solar energy is additionally used. The design of an electric wax melter is similar to the solar model. The advantage is the additional heating of the wax.

The heating element is a dry heating element or a household appliance: a kitchen electric stove heater, an old iron, a photo glosser. The connection occurs through the thermostat from the iron. Thermal contact will help to automatically maintain the set temperature. The heating element inside the wax melter body is insulated with aluminum sheets.

Do-it-yourself centrifugal wax mill

A centrifuge is considered convenient and easy to use. However, to kindle the honeycomb, it must be connected to a steam generator. You can take a centrifuge from an old washing machine. Crushed honeycombs are placed inside the drum in plastic bags for remelting. The centrifuge is turned on and steam is supplied as soon as the drum begins to rotate. The melted wax remains in the bags, but then you will have to filter it manually. The advantage of a centrifuge is the speed of processing of bee products.

How to make a wax melter

There are many primitive ways to help you make a wax melter with your own hands at minimal cost. The simplest example is to melt honeycomb in a pan of boiling water. The mass is filtered through a filter mesh. The wax is left to cool in the bowl, from where it is then taken out in the shape of a thick pancake. To make more effective homemade products with your own hands, use old household appliances, kitchen items, and dishes.

From the juicer

Owners of an aluminum juice cooker can freely use it without modification for melting honeycombs. A kitchen appliance consists of a container for boiling water, on top of which a juice collector with an outlet pipe is installed. The third container is a loading container with holes, resembling a colander. Everything is covered with a lid. Essentially, a juicer is used as a steam wax melter.

The lower container is filled with water and placed on a gas or electric stove. Assemble the remaining elements of the juice cooker. Place honeycombs inside the colander and cover with a lid. The steam melts the wax, it flows through the holes, collects in the juice collector, from where it is drained through the outlet pipe.

The principle of using a juicer for heating wax is shown in the video:

From the washing machine

With simple manipulations, an old automatic washing machine can be converted with your own hands into a convenient wax melter in a couple of hours. The device is first completely disassembled. For homemade leave:

- decorative casing of the machine;

- plastic tank with stainless steel drum;

- rubber hatch seal;

- drain pipe and intake hose.

All other parts are thrown away. Separately, you will have to make a cover for the drum. It is usually cut from sheet steel. After preparing all the parts, begin assembling the device for burning wax:

- The body of the machine is used instead of a stand for the wax melting tank. It is laid flat without the front, top and bottom walls. Spacers must be placed inside the housing so that it does not move apart under the weight of the tank.

- A tank with a drum is placed flat on the body, with the loading window facing up. The rubber collar is left in place to ensure a tight seal on the lid. The tank is connected to the stand from the housing with bolts. All original holes are plugged with rubber stoppers to prevent wax from leaking out. There should be an open drain pipe on the tank. Additionally, 2-3 holes are drilled on the back wall.

- The steam generator is made from a milk can. A hole is drilled in the lid, a fitting is inserted, and the intake hose is connected. Its second end is connected to the drain pipe on the tank.

The structure is ready. The can is filled halfway with water and put on fire. The honeycomb is placed inside the drum, covered with a lid, and pressed down with a weight. When steam appears inside the can, it will be directed through the hose into the tank, where it will begin to warm up the honeycombs through the holes in the drum. Liquid wax with hot condensate will begin to flow from the drum into the tank, and from it through the drilled holes into the trough placed below. After solidification, the melted product will easily separate from the water and float to the surface.

From the refrigerator

Not every refrigerator is suitable for a wax melter. You need to find an old household appliance that has an aluminum casing instead of a plastic inner insert. The refrigerator is freed from all parts. All you need is a body. A hole is drilled in the center of the back wall and a metal pipe is inserted. This will be the drain for the melted wax. The refrigerator is placed horizontally on the stand with the pipe down.The next hole is drilled on one of the side walls of the refrigerator, a metal pipe is inserted, and a high-pressure hose is connected to supply steam.

A filter mesh is fixed inside the refrigerator body, closer to the bottom. Fasteners for frames are placed above or a mesh basket is installed. The second end of the hose is connected to the steam generator. When the water boils and steam fills the refrigerator body, the honeycomb will begin to melt. Liquid wax will flow through the mesh on the bottom and exit through the drain pipe. A tray is placed underneath the refrigerator to collect the melted wax.

Conclusion

A wax furnace of any design is designed and operates on the same principle. Honeycomb melts at high temperatures. If you do not follow safety rules, you can get burns. In the case of a steam generator, there is a risk of it rupturing or the hose breaking if excessive heat creates high steam pressure. An electrical device is dangerous in terms of electric shock when breaking through the heating element. A solar wax melter can be considered the safest, but it is low-productive. Which model to choose is up to the beekeeper himself.