Content

- 1 Device structure

- 2 What types of Granovsky honey extractor are there?

- 3 How the device works

- 4 Advantages and disadvantages of Granovsky honey extractor

- 5 How to disassemble and assemble a Granovsky honey extractor

- 6 Is it possible to make a Granovsky honey extractor with your own hands?

- 7 Conclusion

- 8 Reviews from beekeepers about Granovsky’s honey extractor

Granovsky's honey extractor has gained popularity among beekeepers due to its ease of use. The possibility of continuous operation for a long time allows for quick pumping of honey in small and large apiaries. The device can be manufactured independently, but in terms of performance it is inferior to its factory counterpart.

Device structure

It should be noted right away that Granovsky’s apparatus was designed to match the frame designs of Dadan hives. The design consists of a stainless steel body in the shape of a large barrel. Inside there are cassettes for attaching frames. The inner drum is made of ordinary metal with a protective polymer coating. The rotation of the cassettes is carried out by an electric drive.

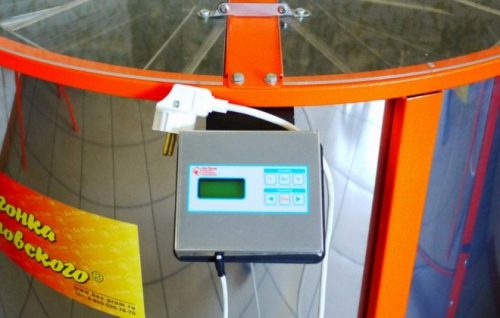

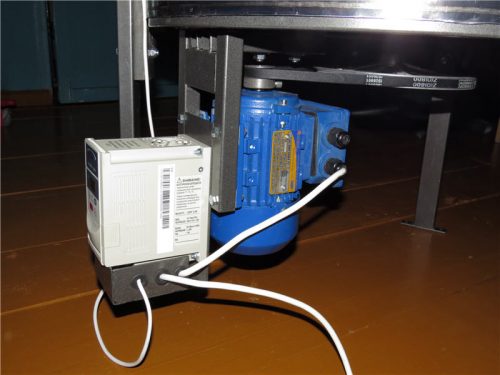

The cassettes are connected to the rotor by a spring mechanism. Simultaneous rotation during operation prevents the cells from sticking. The rotor rotates on a bearing pair. The manual drive and electric motor are located under the tank. If necessary, the elements can be easily removed and replaced.The electric drive is controlled by the included remote control.

What types of Granovsky honey extractor are there?

Different models of Granovsky devices differ in the number of cassettes for frames that can be accommodated when pumping out honey, as well as their functionality. For small models designed for 2, 3 or 4 frames, the cassettes do not rotate. The device is in demand by owners of small apiaries with a maximum of 10 hives. The honey extractor is compact, light weight, and low cost.

For owners of medium-sized apiaries containing about 40 hives, Granovsky’s semi-professional apparatus is ideal. It is designed for four frames, but the cassettes are installed rotating. The principle of operation and control is simple and similar to household models. The only difference is the increased productivity.

Industrial and private professional apiaries consist of more than 40 hives. Large volumes of honey are pumped out using Granovsky devices with six or eight rotating cassettes. The body is equipped with a spacious honey collecting pocket. Honey is drained without filters.

The production of Granovsky honey extractors is established by many manufacturers. The most famous company on the domestic market is Bi-Prom. Models from this company are equipped with a flat bottom. Analogs from other manufacturers have a cone-shaped bottom.

The manufacturer Bi-Prom equips its devices with two types of electric drives. Models operating on 12 volts are more convenient to use in an apiary where there is no electrical network. The connection is made to the battery. Models operating from 220 volts are more powerful and productive. Such honey extractors have gained greater recognition among beekeepers.

Video review of Granovsky's honey extractor:

How the device works

The convenience of the honey extractor lies in two operating modes:

- In manual mode, the rotating rotor stops after complete extraction of honey from one side of the frame. The cassettes rotate. Further pumping occurs with rotor rotation in the opposite direction.

- In automatic mode, the rotor rotates constantly until all the honey is pumped out from both sides of the frames.

The beekeeper chooses the operating modes at his own discretion. If necessary, set the duration of operation, the signal for the completion of pumping, and the duration of the rotor stopping to rotate the cassettes.

The sequence and rules of operation are shown in the instructions. In general terms, perform the following actions:

- Frames filled with honey are placed in the cassettes.

- The beekeeper sets the mode, additional options, and puts the device into operation by pressing the start button.

- The honey extractor rotor begins to rotate. From slow speeds there is a smooth acceleration to the set speed.

- When all the honey has been pumped out of the frames, the rotor gradually reduces the rotation speed and stops.

If there is still honey left in the honeycombs or it is quickly pumped out before the rotor starts to stop, the mode is selected incorrectly. The beekeeper sets new parameters through practical selection.

Advantages and disadvantages of Granovsky honey extractor

The honey extractor is the beekeeper’s individual equipment. Each owner identifies positive and negative aspects for himself. In general terms, the Granovsky apparatus has the following advantages:

- Small size is determined by the type of model and how many frames the device is designed for. In general, all honey extractors are compact and easy to transport by car.

- The use of thin stainless metal allowed the manufacturer to reduce weight.The honey extractor is easy to carry around the apiary by hand.

- An undeniable advantage is the high speed of pumping out honey.

- Thanks to the electric drive, continuous operation is established until all frames are free of honey.

- The operation of the Granovsky apparatus is easy to control. Simple maintenance consists of washing after completion of work. All failures not related to electronics can be easily repaired yourself.

- The cost of a honey extractor is affordable for the average beekeeper.

The thin stainless steel body resists light impacts. There are no dents on the walls. Stainless steel washes well and is resistant to corrosion. The absence of closed areas makes cleaning easier.

The Granovsky apparatus is universal. It is used stationary and in the field. Any honey extractor is suitable for amateur and professional apiaries. Only performance depends on an incorrectly selected model.

Beekeepers speak well of the honey extractor, but highlight three of its disadvantages:

- It is difficult to attach a heavy metal tap to a thin body. Stainless steel “plays”. If you apply a lot of force, the body can be deformed.

- The manufacturer did not think through reliable fixation of the legs. Vibration weakens them and a rumble appears.

- As the tank is filled with honey, the rotation speed of the frames decreases and productivity drops.

All shortcomings are insignificant and can be easily eliminated. Instead of a metal tap, a lightweight plastic analogue is installed. The fixation of the legs is checked before each pumping. The tank is not overloaded with honey. The container is emptied after filling more than 40 liters.

How to disassemble and assemble a Granovsky honey extractor

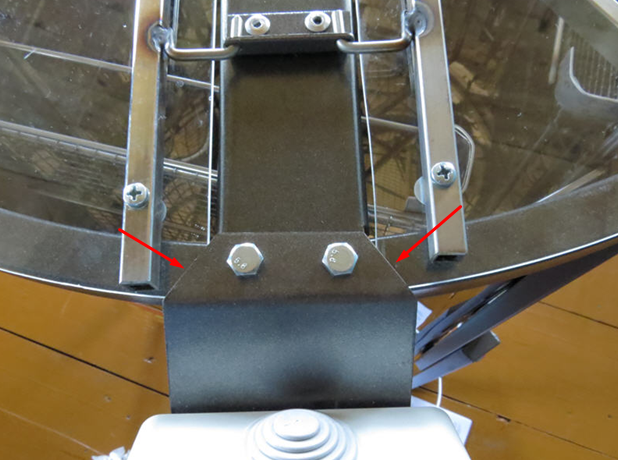

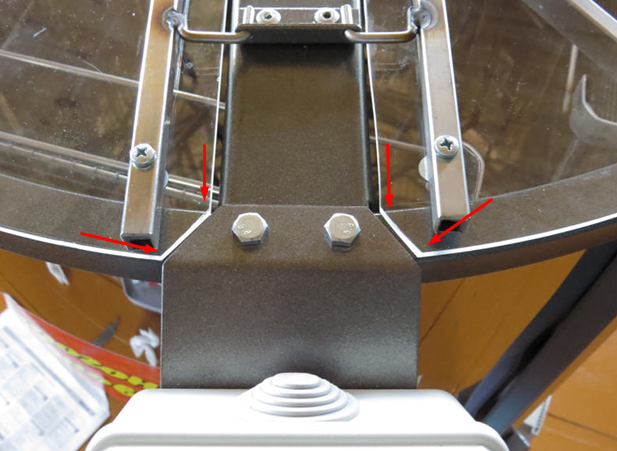

The honey extractor is assembled according to the attached instructions. The device arrives from the factory in slatted packaging.The wooden lathing protects the body from mechanical damage during transportation. The electric drive with the control unit are supplied in a separate box. After unpacking, they are installed on the honey extractor. The drive is bolted under the housing from below. The pulleys are connected by a belt drive.

According to beekeepers, difficulties may arise during installation of the control unit. If you simply bolt it to the body, the mounting plate presses the corners of the honey extractor covers, and they do not open.

The problem is solved by sawing off the corners of the lids. The material is easily cut with a hacksaw blade.

Alternatively, the block can be secured with a fastening plate under the crossbar. The lids will open freely without sawed corners. However, such installation is not possible if the rotor axis shifts.

Disassembling the Granovsky apparatus occurs in the reverse order

Is it possible to make a Granovsky honey extractor with your own hands?

To assemble a Granovsky honey extractor yourself, it is optimal to choose a model with 2, 3 or 4 frames. The body will be an old washing machine. The tank should not be aluminum, but stainless steel and covered with a lid. The drain hole at the bottom is used to fix the tap through which honey is taken. The tank is installed on legs. The height is determined individually so that a container for draining honey fits under the tap. A counterweight is attached to the opposite side of the crane.

The drive is used from a washing machine. To manufacture the rotor and cassettes, it is best to familiarize yourself with the design of a factory honey extractor from a familiar beekeeper. The dimensions of the elements will have to be calculated individually for the available tank.

A homemade honey extractor is much inferior in performance to Granovsky’s factory apparatus.Incorrect calculations of the rotor and cassette sizes will lead to imbalance. A working honey extractor will rattle and break honeycombs.

Conclusion

Granovsky's honey extractor will save the beekeeper from grueling manual work. If you follow the instructions and use them carefully, the device will work for many years and will quickly pay for itself.