Content

This is a plastic container where all sewage waste water is collected for recycling. It is used in cases where there is no or impractical connection to a centralized sewerage system.

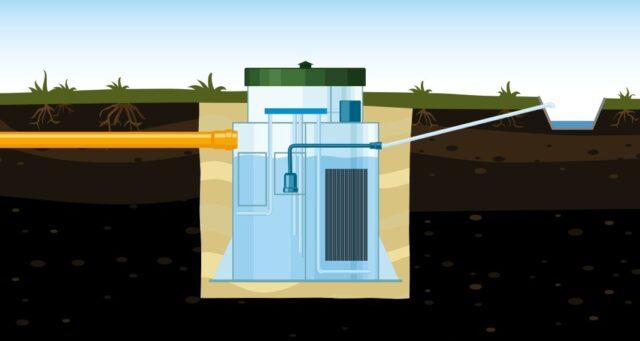

In a simple device, purification takes place in 2 stages: decomposition of heavy components and secondary waste treatment, followed by removal of the purified liquid to the outside - usually into a drainage system with a ventilation outlet (for further purification).

What materials are septic tanks made from?

Plastic septic tanks are made from polyethylene, polypropylene, fiberglass.

The most budget material - low-pressure polyethylene. Rotational molding makes it possible to obtain seamless septic tanks. This ensures their tightness, which is especially in demand in areas with high groundwater levels (GWL).

Unfortunately, the production method does not allow us to obtain at least approximately the same wall thicknesses - they can differ by half (8-17 mm).In addition, ethylene itself is not particularly strong, so it is reinforced with stiffening ribs along the body and internal partitions. The resulting chambers are connected by overflows.

pros polyethylene septic tanks:

- resistant to aggressive environments, rusting, siltation of walls, and soil characteristics;

- solidity, seamlessness;

- large operating temperature range: -50+700WITH.

Minuses:

- Low-density polyethylene is not particularly durable and requires reinforcement.

Polypropylene septic tanks - they turn out to be stronger and tougher, although they are also inexpensive. Polypropylene sheets are welded by extrusion, which makes it possible to make a variety of protruding elements on the body that enhance rigidity.

Polypropylene compared to polyethylene:

- withstands temperatures up to +1400C, not subject to temperature deformation;

- harder and more durable.

In general, it is considered an intermediate material between polyethylene and fiberglass.

Fiberglass septic tanks - are considered relatively expensive. Made from composite material, they can already withstand soil pressure at a depth of 3 meters, where they are preferred to be installed.

pros:

- resistant to any aggressive environment;

- light;

- anti-corrosion and durable (up to 50 years).

Minuses:

- fragility;

- not the strongest of plastics; in practice, polypropylene is stronger than fiberglass.

Advantages and disadvantages of plastic septic tanks

The following advantages of plastic septic tanks can be noted:

- ease of maintenance and operation;

- complete tightness (unlike concrete rings, bricks and other “folk” sewerage options)

- compactness and light weight;

- safe for the environment, no specific odors;

- can be installed anywhere;

- durability and corrosion resistance.

Cons (mainly for simple septic tanks):

- lower strength - compared to concrete, but this is fully compensated for by competent installation by specialists;

- reliable anchoring is necessary - a light hull without water can be squeezed out by groundwater or soil during swelling.

Types of plastic wastewater treatment plants

For clarity, let’s consider them for different degrees of purification using the example of Eurolos plastic septic tanks, as the most advanced Russian treatment facilities for country houses with permanent and seasonal residence:

Aeration unit Eurolos Pro

Aeration unit Eurolos Pro — high degree of wastewater purification (98%). It is achieved through biological wastewater treatment - complex devices with compressors, aerators and airlifts.

Body material – monolithic sheet polypropylene. Purified water can be discharged either into a drainage ditch or onto the ground surface.

Eurolos PRO is a modern innovative Russian development, adapted to Russian conditions. Based on technology used in municipal wastewater treatment plants, but tailored to the end user. Jet aeration of wastewater using ejector technology.

Differs in the following qualities:

- strength - the cylindrical shape of the body allows it to withstand significantly greater soil compression (compared to rectangular ones) with the same material consumption;

- reliability – increased by the lack of automation in the technology;

- compactness – due to intensive cleaning methods;

- stability - microorganisms on an inert carrier make it possible to withstand the discharge of prohibited toxic substances into a septic tank, plus they increase the degree of purification;

- maintainability - most key elements are easy to find in hardware stores.

Conclusion: Such installations are for country houses, small hotels/inns, villages.

Local wastewater treatment plant

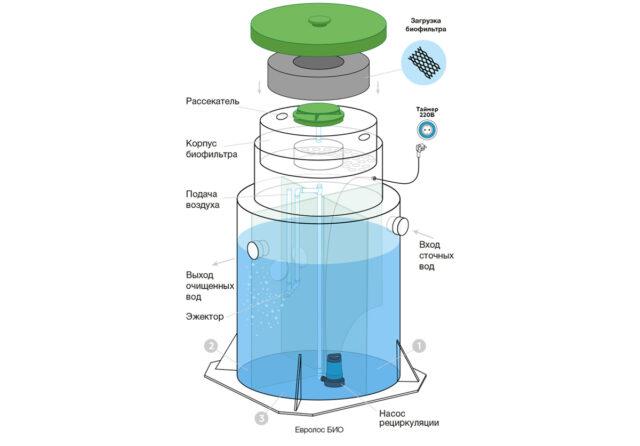

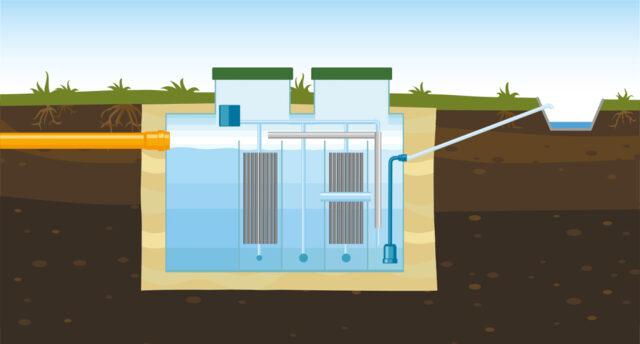

Local wastewater treatment plant - Eurolos Bio (purification up to 92-97%).

This is a pumping autonomous sewage system consisting of 3 compartments. Material – polypropylene. The station includes: pump, ejector, biofilter.

During operation, mechanical and biological cleaning is performed. The wastewater circulates in the compartments, repeatedly passing through a biofilter in a bioreactor with plastic loading. The cycle repeats every hour.

If there is a power outage, the station operates in normal mode for 2 days, then switches to the non-volatile septic tank mode. Those. Maintenance is required once every 2 years according to the passport, but this depends on the intensity of use.

Conclusion: a universal option for permanent and seasonal residence in suburban areas and cottage villages.

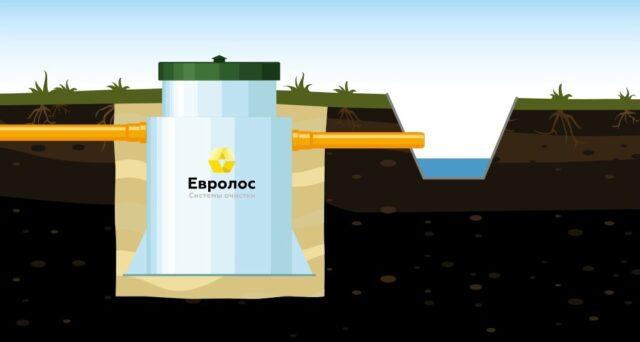

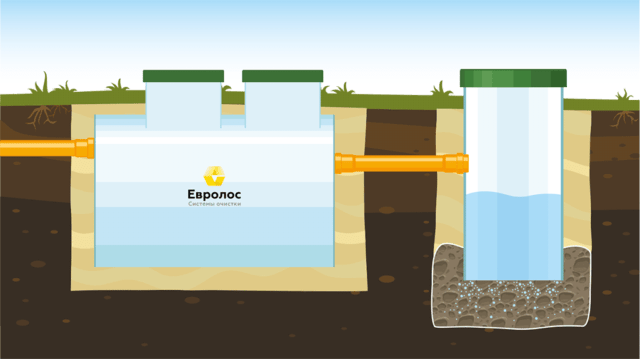

Overflow anaerobic energy-independent septic tank Eurolos Eco

Overflow anaerobic energy-independent septic tank Eurolos Eco (cleaning up to 60-70%).

Body material – monolithic sheet polypropylene. It consists of 3 compartments where triple cleaning takes place: mechanical, biological and final settling. The purified water must then be supplied to the drainage for further treatment (filtration field or drainage well). A non-volatile septic tank is only suitable for installation on sandy soils with low groundwater level.

Conclusion: for non-permanent residence. For example, when visiting a dacha only on weekends.

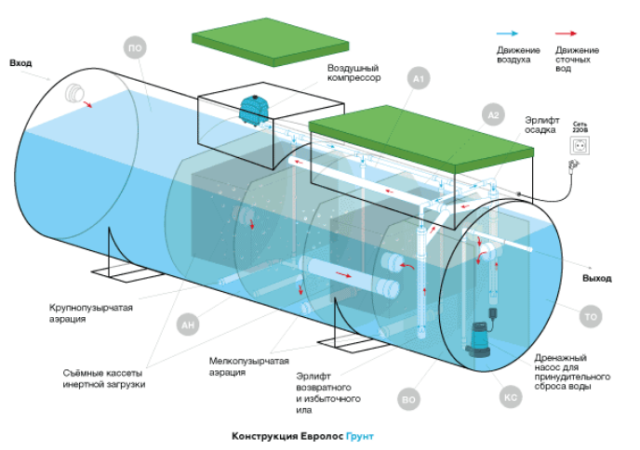

Deep biological treatment station Eurolos Ground

Deep biological treatment station Eurolos Ground — for areas with high groundwater levels, as well as poorly absorbent soil types: loam, peat, etc. Compressor aeration unit with two aeration tanks. Wastewater treatment reaches 99%.

In conditions of high groundwater level, the installation of treatment facilities is very difficult, as is the drainage of treated water. This led to a change in the layout of the device in order to reduce the depth of the pit dug under it. The increase in length led to an increase in productivity.

The full cycle of mechanical-biological cleaning is eight-stage:

- Mechanical.

2-3. Biological: under aerobic and anaerobic conditions.

- Sludge separation.

- Aerobic tertiary treatment.

- Fixation of spent biofilm.

- Disinfection and discharge of purified water.

- Sludge stabilization (anaerobic).

Conclusion: for an area with a high groundwater level, for swampy areas.

Which plastic septic tank to choose for a summer house or private house

First of all, when choosing, operating conditions, free space, groundwater level and the desired degree of purification are taken into account. You should also focus on cleaning performance and expected load.

Eurolos BIO is applicable almost everywhere, as a universal station - both for a home with permanent residence and for a seasonal dacha. If you rarely live at your dacha, then you can choose Eurolos ECO, but provided that the ground level is low and the soil absorbs moisture well. For swampy areas or in quicksand, only Eurolos Soil is suitable using formwork during installation.