Content

It doesn’t take long to create a blueberry harvester with your own hands. The device resembles a small bucket with teeth. It is more important to assemble correctly so that the comb does not injure the plant branches.

How to pick blueberries

Picking small berries is a boring, long, exhausting task. Blueberry lovers are trying to speed up the process using different methods and devices. However, regardless of the chosen method, it is advisable to adhere to the basic rules of harvesting:

- Blueberries begin to ripen around July. It’s worth getting your bearings at this time and preparing containers and equipment for picking berries in advance.

- Blueberry bushes can grow for more than 20 years. The berries are collected from young plants no older than 15 years. These blueberries contain more vitamins.Attention! The approximate age of the bush is determined by its branches. The more lateral shoots, the older the plant.

- Only ripe berries can be harvested. They can be identified by their blue with a black tint. Unripe blueberries will not ripen, and overripe berries will quickly disappear.

- According to popular belief, blueberries are harvested before the full moon for quick consumption. These berries taste better. For long-term storage of the crop, it is better to harvest it yourself after the full moon.

- It is optimal to start harvesting early in the morning or in the evening. Dry, cool weather is optimal.

- It is better to put blueberries in wicker baskets, where the berries are better ventilated through the cells. In extreme cases, a plastic container will do.

Avid forest lovers do not recommend using combines, scrapers, rakes and other devices for collecting blueberries. The mechanisms injure the fruit branches. Next year, the yield of damaged bushes will decrease.

Pros and cons of blueberry picking devices

Any blueberry picking machine is beneficial to humans and harmful to the plant. Using a combine harvester speeds up harvesting by 3 times, which is the main advantage of the device. A person does not pick one berry at a time, but grabs a whole handful at once. The combine has no other advantages.

There are more disadvantages to berry picking devices. Any combine takes some getting used to. At first, the assembler's hand gets very tired. Homemade combine harvesters rarely have rakes that meet the standard. Many berries slip between the sparse teeth, and the thick comb peels off the branches along with foliage, bark and fruiting buds. The next year the shoots will bear worse as the plant recovers.

Is it possible to harvest blueberries with a combine?

In the countries of the post-Soviet space, the taboo on tools for picking blueberries still remains. There is no strict control, it’s just that no one has repealed the law yet.At that time, primitive harvesters were being explored. After their use, blueberry productivity decreased and the plant required a long recovery period.

New and improved harvesters cause minimal damage to the branches. The mechanisms are officially approved in Sweden and Finland. Norwegians use combine harvesters in large numbers.

The minimal damage from a modern combine can be judged from the video:

How to pick blueberries with a combine harvester

Any scraper for picking blueberries consists of a comb, a berry picker and a handle. There are a variety of shapes: oval, elongated, rectangular, round. Berry pickers can be hard or soft in the form of bags. The principle of using any combine is the same. The bucket is held by hand by the handle. With the other hand, they direct the twigs with berries onto the comb. As the combine moves forward, fruiting shoots slip between the teeth. Blueberries with a diameter larger than the gap will get stuck between the pins. The berry comes off the stalk and rolls into the berry collector.

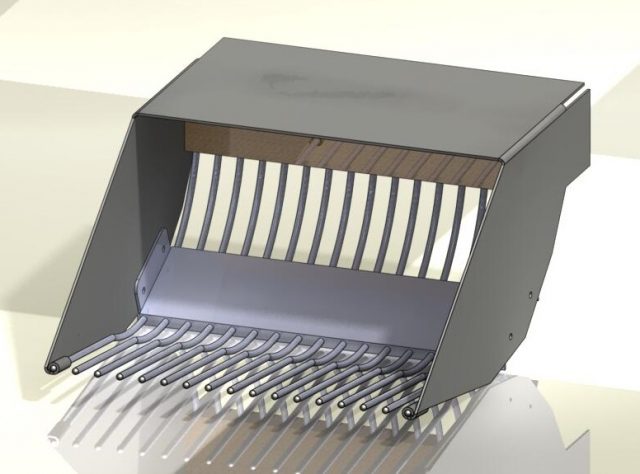

How to make a blueberry harvester

The device is assembled from plastic, wood, and metal. The berry collector is a box-shaped scoop or a cloth bag. The main working mechanism of the combine is the comb. The optimal length of the teeth is 6 cm. The width of the gaps is 5 mm. The comb can be adapted from a store-bought comb or made independently. Typically, the material for the teeth is steel wire or wooden kebab skewers.

Watch the video for more details about the homemade harvester:

Grabber for picking blueberries from a metal sheet

A durable combine is made from thin stainless steel sheets.In extreme cases, galvanizing is suitable. Consists of a scoop for collecting blueberries from a ladle and a handle. To manufacture the first element, perform the following steps:

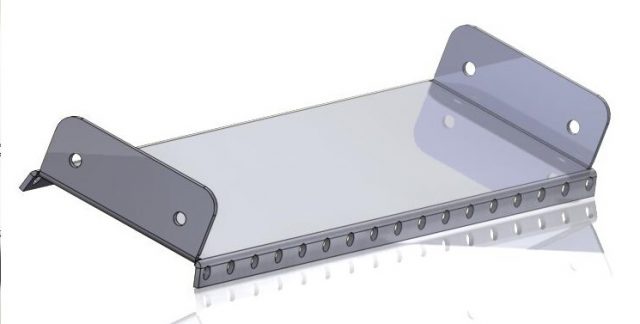

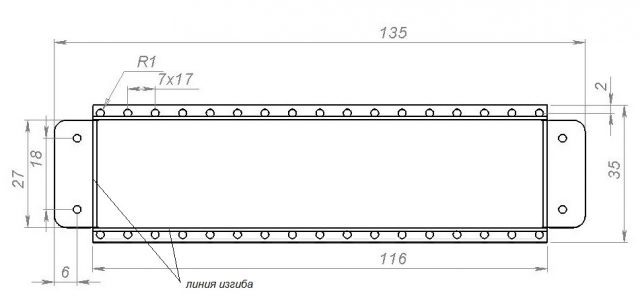

- A rectangular blank is cut from sheet steel. According to the drawing, the stiffener is bent. On long curved shelves, holes are drilled in increments of 5 mm, into which wire teeth will be inserted.

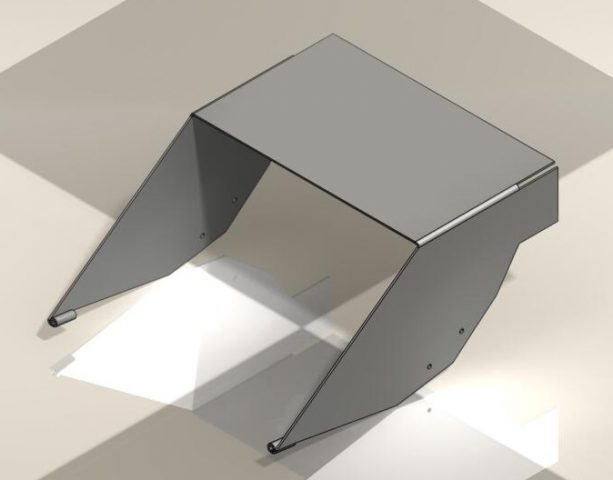

- Following the drawing, a housing element is cut out of metal. The side shelves are bent, forming a U-shaped blank.

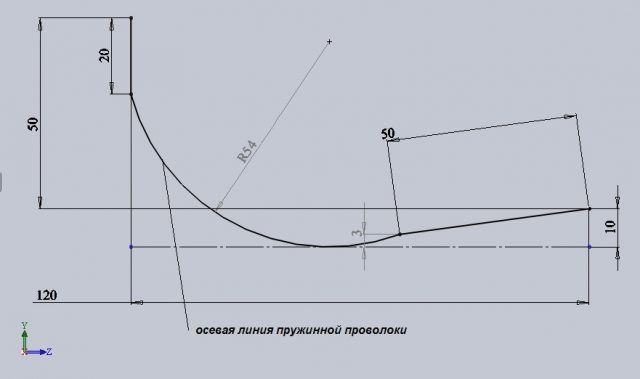

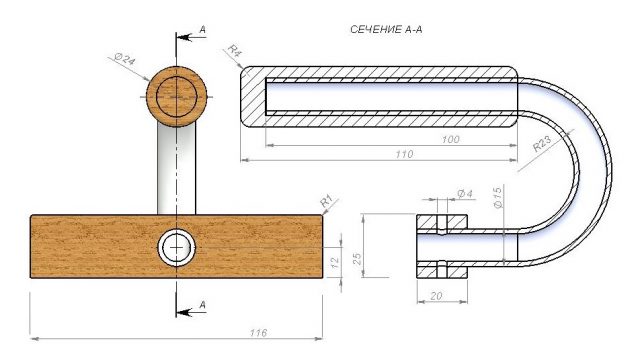

- The teeth of the combine comb are made of stainless, bend-resistant wire 2 mm thick. The elements must have the same bend. It is more convenient to bend the teeth on a wooden template.

- The last element of the combine bucket is the mounting block. A wooden strip 10 mm thick is drilled every 5 mm. The fastening bar will have teeth inserted into it.

When assembled, you should get a bucket, but for now without a handle.

For the handle of the combine you will need a piece of aluminum or metal-plastic pipe. The workpiece is bent in the shape of a “U”. A wooden round handle is put on one end. The second end of the pipe is inserted into a hole drilled in the center of the block. Its size is equal to the parameters of the fastening bar for the teeth.

When all the components of the combine are prepared, assembly begins. First, the bucket is assembled. The body is connected to a stiffener and a fastening bar. Self-tapping screws and rivets are used for fixation. Wire teeth are placed in the holes with glue so that they do not fall out. The handle is attached with a block to a fastening block fixed on the bucket. Two wooden elements are tightened with self-tapping screws.

A ready-made scoop for picking blueberries is tested in action. If the teeth seriously injure the blueberry branches, check the gaps. Perhaps some elements are bent and tightly pinching the shoots.

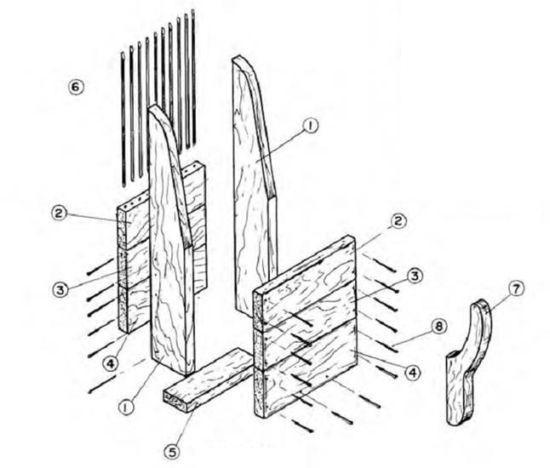

Wooden blueberry picker

A simple DIY blueberry harvester is made from plywood. Essentially, the device resembles an excavator bucket. 5 blanks are cut out of plywood: side elements of the same shape and size, top cover, back plug and bottom comb. Four fragments can be easily cut out with a jigsaw. The difficulty lies in making the fifth part - the comb. On a rectangular piece of plywood, teeth are precisely marked with the same gap. Each cut is made carefully so as not to break the comb element.

The blanks are connected to each other with self-tapping screws. A U-shaped handle is attached to the top cover of the combine bucket. It is made from a thin tube or steel plate.

Blueberry harvester from a plastic bottle

A primitive harvester can quickly be built from PET containers. The bottle will act as a fruit collector for blueberries and a comb. If you come across a fruitful bush while walking in the forest, but don’t have a combine harvester with you, you should look in your backpack. Ketchup, kefir or other bottled product taken on a picnic will have to be used quickly. If you have a choice, it is advisable to take a rigid container with a wide neck of small volume. Additionally, you will need a stick, which is not in short supply in the forest, a piece of rope or tape. Tools you need are a knife or scissors and a marker.

Having laid the bottle on its side, use a marker to draw a window in the form of a flag on the side wall. The working side, with its teeth directed towards the bottom of the container, is shaped like the English letter “W”. According to the marking, a fragment is cut out with a knife or scissors. The edges of the comb are sharp enough to cut blueberries.The stiffer the wall of the bottle, the stronger the comb will be.

The cut out fragment is thrown away. It is not needed for the combine. The bottle is tightly tied to the stick with the bottom up. It is advisable to use tape. The bottle will slide off the rope. Harvesting is carried out by pulling the device along the branches. A sharp blueberry comb cuts the berries with three teeth, and they roll into the neck of the bottle. When the fruit collector is full, unscrew the plug. The berries are poured into the bag through the wide neck.

DIY blueberry harvester drawings

There are a lot of drawings of combine harvesters. The principle of their design is almost the same. A metal and a wooden ladle were considered. It remains to familiarize yourself with the drawing of the combined harvester. The difference between the device for picking blueberries with your own hands is that the teeth of the comb are not cut out of plywood. The elements are made from pieces of steel wire or wooden skewers for stringing kebab. The pins are driven into drilled holes at the end of the bottom of the bucket.

Conclusion

A do-it-yourself blueberry harvester must be assembled with all responsibility. If the result is a defect and the comb breaks the branches, there is no need to be lazy in correcting the defects, otherwise you may be left without a harvest next year.