Content

The horned hive received its name due to the presence of small pins that protrude from the body or bottom. This design was invented by Mikhail Palivodov. This design was developed as the most simplified and easy to use. It is worth noting that the original idea worked out. In addition, of particular importance is the fact that, if necessary, beekeepers can use Dadan or store-bought frames.

Distinctive features of horned hives

Considering the distinctive features of horned hives, it is worth noting that ordinary ones can be made in several variations:

- with shaped ends, as a result of which they can be attached to each other;

- with a smooth surface.

The hive from Mikhail Polevody is made much more cunning. The sections are made of 4 knocked down boards; bars are used as fastening, which protrude above the body and slightly do not reach the bottom. During the installation process, sections can be placed on top of each other, while the bars are not fastened together, and the body cannot be moved.

It is worth considering that a small gap (5 mm) is deliberately left into which you can insert a chisel and separate the modules if they were glued together with propolis.

Advantages and disadvantages

Judging by the reviews of beekeepers, a horned hive has the following advantages:

- the design is quite easy to make yourself;

- Dry shawl of any breed can be used as material;

- scraps from waste can be used for bars and frames; as a rule, the quality of the finished structure does not suffer from this;

- in the process of making a horned hive, you do not need to have a special tool;

- sections consisting of 8 frames fit perfectly under the core;

- at the request of the beekeeper, dadan or store frames can be installed in the hive;

- Such designs are inexpensive, which is very important both for novice beekeepers and for owners of large apiaries.

Over the years of use, no shortcomings have been identified. Horned hives are considered a successful type of design, which are easy to use and do not require large costs to manufacture.

Equipment

In order to properly collect horned evidence for the apiary, it is recommended that you first study the complete set of the structure. Designs intended for bee colonies include the following elements:

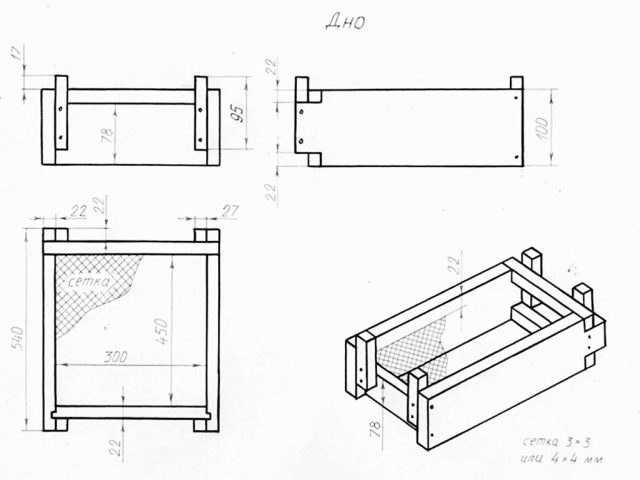

- bottom – as practice shows, it can not only be deaf, but also consist of a special mesh, the first option is used in winter, the second - mainly in summer;

- frame - the capacity is up to 8-10 honeycomb frames; it is important to consider that the number of frames used depends entirely on the design features;

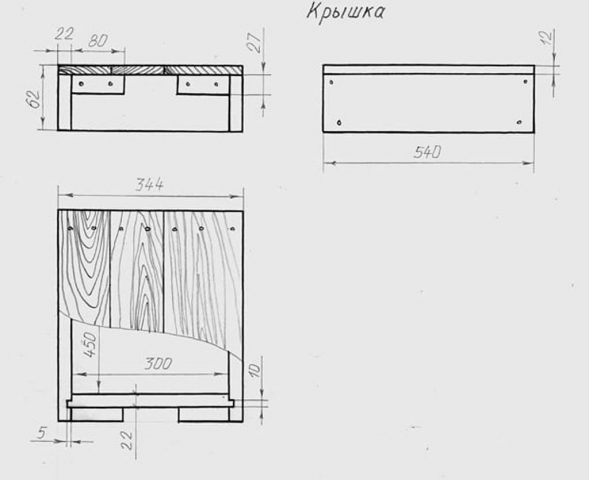

- frame – it is used as an alternative solution for the ceiling or as a canopy; as a rule, it is installed on the upper part of the structure – on top of the body.

If the horned hives are planned to be installed in regions with low temperature conditions, then it is necessary to first insulate the bee houses using polystyrene foam for this purpose.

How to make a horned hive with your own hands

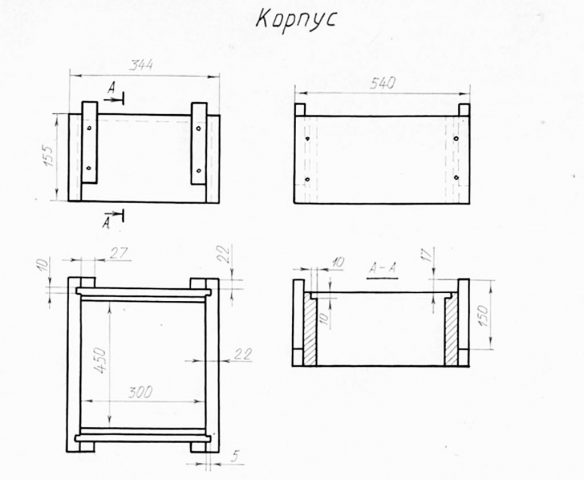

Making your own horned hive at home is not as difficult as it might initially seem. All that is required in this case is to follow all the recommendations and carry out the assembly process step by step. To simplify the work, it is necessary to carry out the work according to the attached drawings, which indicate the dimensions of the structure.

Horned hive dimensions

Before you begin the process of assembling a structure to house bee colonies, it is recommended to understand what size the future hive should be:

- height of extension bodies – 153 mm;

- width of the side panels - 535 mm, in this case it is necessary to take into account the standard width, 16 mm - distance to the walls, wall thickness and external protrusions of 40 mm;

- the width of the front and rear walls is 389 mm, while it is necessary to take into account 10 hundred frames, outer tenons and a special gap of 5 mm;

- folds located in the upper part of the front and rear walls - 8x11 mm;

- spikes located on the front and rear walls - 7x11 mm;

- side grooves used for assembling the body - 7 mm wide, 10 mm deep, the distance from the edge of the board should be 20 mm.

Before you begin assembly, you need to prepare a flat surface.

Drawings of horned hives

During the work process, it is worth using drawings for a horned hive with 10 frames.

Required tools and materials

To make horned hives, it is recommended to use boards from spruce trees. It is best to use boards sawn from dead wood or dried willow, which is quite light. Some beekeepers note that untreated wood can be used, which reduces the cost of the finished structure.

The most budget option is a shalevka, and the width must be chosen as standard and be 25 mm. After the material has been processed on a jointer, the required thickness of 22 mm will be obtained.

Installation work must be carried out after all the materials and tools necessary for the work have been prepared. During assembly, you will need to have a mallet on hand, with which you can fit the tenons into the grooves, a screwdriver, screws and a saw.

Build process

To create the body, you will need boards, which are cut into small bars measuring 22 x 27 mm - these will be the horns. Using a milling cutter, small recesses are made in the boards for installing frames. The size of the hanger should be 10 x 10 mm. The horns are installed from the end side.

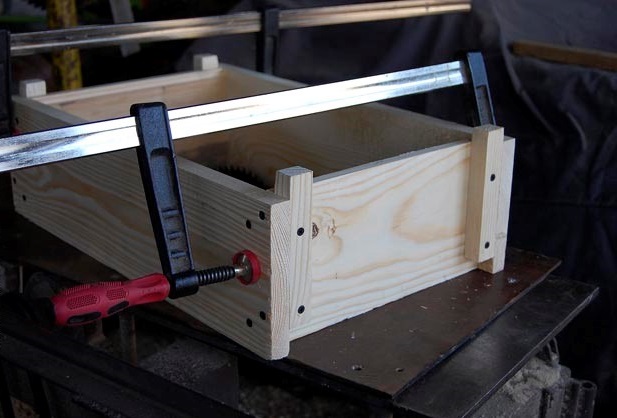

After this, the housing for each section is folded. The boards must be folded in such a way that there are no gaps between them. Fastening is carried out using self-tapping screws.

Be sure to check the corners to ensure they remain straight.After the first 2 compartments are made, it is necessary to check the joining - there should be no gaps. The thickness of the board used must be at least 22 mm.

After this, it is worth checking the internal corners for cracks.

To make the bottom, take boards 22 mm thick and bars measuring 22 x 22 mm. Using a workbench, cutouts are made on the side walls.

The assembled elements of the lower tier are fixed with a clamp and fastened with self-tapping screws.

During assembly, it is necessary to leave a gap for the tap hole. A mesh is inserted into the bottom.

Methods for keeping bees in horned hives

As a rule, the process of keeping bee colonies in horned hives is not much different from keeping bees in conventional structures. A distinctive feature is the fact that when working in an apiary you will have to operate not with hundreds of frames, as is usually the case, but with sections, of which there should be a large number.

It is important to consider that a large amount of time should be devoted to working with the bottom - it must be replaced regularly. On hot summer days, it is recommended to use a mesh, which ensures an influx of fresh air, as a result of which bees do not gather on the front walls of the structure. In addition, a mesh bottom in the summer allows you to get rid of ticks, which fall off insects during movement.

Thanks to the solid bottom, optimal temperature conditions are maintained in winter. In the spring, when bee colonies are checked, the bottom must be replaced. Determining the presence of brood is quite easy and does not require removing sections. It is enough to put your hand on the frame and if you feel warmth, this indicates the presence of brood in the bee colony.

Conclusion

The horned hive is considered a fairly simple and popular design used by beekeepers. During the production process, it is recommended to take into account that the number of frames used can be any, depending on the preferences of the beekeeper. As you know, there are no clear rules in the production process, as a result of which you can choose any size and shape. If we talk about traditional houses for bee families, they should include 8 frames up to 22 mm thick.