Content

- 1 What types of hive frames are there?

- 2 How to determine frame sizes

- 3 Distance between frames in the hive

- 4 General principles for making frames for bees

- 5 Wire arrangement on the frame

- 6 Tools for making hive frames

- 7 Options for the correct placement of frames in the hive

- 8 Production of innovative frames for bees

- 9 Conclusion

Frames for hives come in different sizes, depending on the design and dimensions of the house. The apiary equipment consists of four slats, knocked down into a rectangle. A wire is stretched between the opposite strips to secure the foundation.

What types of hive frames are there?

Frames for bees differ not only in size, but also in purpose. Inventory is used to perform various tasks.

Varieties of bee frames

Depending on the installation location, there are two main types:

- Nesting models are installed at the bottom of the hive. The equipment is used to arrange the brood zone. The design of the nesting and honey frames in the beds is the same.

- Store-bought half-frames are used during honey collection. The equipment is installed in the upper housings placed on the hives. If the design of the lounger includes extensions, then you can use half-frames here too.

According to their intended purpose, there are the following types of apiary equipment:

- Coverts hundred frames can be of different sizes. They do not have a special design. Hundreds of frames are used to enclose the nest on both sides to preserve heat. This is where the name came from.

- Framework the feeder has similar dimensions to the honeycomb frame and is installed in its place. The equipment is used to feed bees with syrup.

- Incubator consists of a hundred frame with brood or sealed queen cell enclosed in a box. The equipment is used during the cultivation of queen cells.

- Nursery also called grafting frame. The inventory consists of a simple hundred frame. The sides are equipped with moving slats. The nursery is in demand during the installation of cages with the queen.

- Outpost the frame is often called a board. It is assembled from a frame covered with thin planks. Install a guard board in the hive to preserve heat. Beekeepers also make equipment from polystyrene foam or cover the frame on both sides with plywood, and fill the internal space with thermal insulation.

- Construction honeycomb frames are used in the production of comb honey and wax. The equipment helps fight drones and mites. In the spring, drones are hatched on construction frames to mate with the queen.

- Sectional models are used for the production of comb honey. The inventory appeared in 90 of the last century. The sections are made of plastic. Frames for comb honey are inserted into a half-frame measuring 435-145 mm.

What all types of apiary equipment have in common is a standard size corresponding to the dimensions of the hive used.

More information about apiary equipment can be found in the video:

What framework are flightless bees on?

Flightless bees are considered to be young animals aged from 14 to 20 days. Insects work inside the hive and occasionally fly out only to empty the intestines. When old bees are engaged in honey collection, flightless young ones remain on hundred frames with brood.

How to determine frame sizes

The honeycomb frames are installed inside the hive, from here their size is determined. There are standards for all types of houses.

Basic Framework Standards

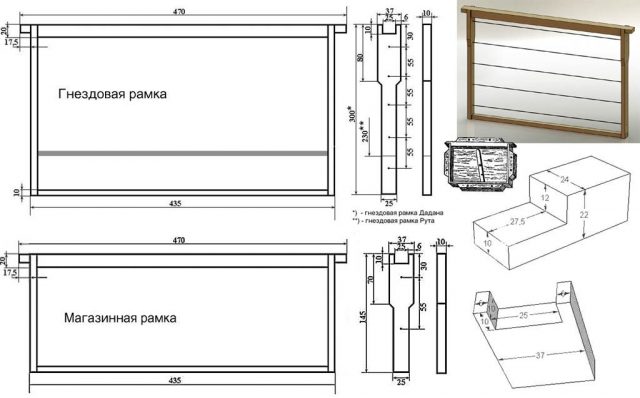

If we talk about standards, the dimensions of frames for beehives are as follows:

- 435x300 mm are used in Dadan hives;

- 435x230 mm are used in Ruta hives.

With a slight difference in height, standard models are suitable for two-tier and multi-tier hives.

However, Dadan hives are used with magazine extensions. The suitable frame sizes are as follows:

- 435x300 mm are placed in sockets;

- 435x145 mm are placed in honey extensions.

The top rail of any model is slightly longer. Protrusions 10 mm long are formed on both sides for hanging in the hive. The width of the slats corresponding to the thickness of the frame is 25 mm.

Less common are hives that require the use of honeycomb frames of other standards:

- they place a frame of 300x435 mm of the Ukrainian model in the hive, characterized by a narrow body and increased height;

- 435x145 mm is used in low but wide hives.

In Boa constrictor hives, non-standard sized frames of 280x110 mm are used.

What factors influence the choice

The choice of frame size depends on the type of hive used. In turn, the choice of design depends on the purpose of the equipment.

Distance between frames in the hive

Bees seal gaps less than 5 mm wide with propolis, and fill spaces wider than 9.5 mm with honeycombs. However, in the hive, a so-called bee space is formed between the honeycombs and the wall. Bees do not build it up with honeycombs and propolis.

The bee colony leaves up to 12 mm of space between the foundation with the brood, and up to 9 mm between the honeycombs. Taking into account the bee space, when installing frames, beekeepers maintain the following clearances:

- between the side of the frame and the wall of the hive - up to 8 mm;

- between the top rail of the frame and the ceiling or lower element of the hundred-frame frame of the higher case - up to 10 mm;

- between honeycomb frames in the nest - up to 12 mm, and in the absence of separators, the gap in the spring is reduced to 9 mm.

Maintaining clearances creates optimal conditions for the development of the bee colony in the hive.

General principles for making frames for bees

The process of assembling frames for hives follows the same principle. Equipment for comb honey consists of 4 slats, knocked down into a standard size rectangle. The length of the top rail is always longer than the bottom bar. The protrusions form hangers for installing the structure in the hive. The frame inside the house is supported by protrusions on the side walls.

A common material is wood. Modern equipment began to be produced from plastic. However, many beekeepers prefer natural material.

Drawings and dimensions of frames for hives

Initially, before production, the beekeeper needs to decide on the size. When assembling a store and nesting frame for a hive with your own hands, you don’t need to look for different drawings. One diagram is enough, since the designs are identical.Only the dimensions differ in the drawing.

Tools and materials

The materials you will need are dry slats, nails, screws, and wire for tensioning the strings. The ideal tool to have is a woodworking machine. The planks can be cut and sanded by hand, but this will take longer and be more difficult.

How to make a beehive frame with your own hands

Modern innovative frames are made of plastic, but not many beekeepers like artificial material. Beekeepers traditionally prefer wood. The inventory manufacturing process consists of two main actions: preparing the planks and assembling the structure.

The planks are cut to the required dimensions according to the drawing, sanded on a machine or manually with sandpaper. Assembly is carried out using self-tapping screws to ensure connection strength. You can use nails, but then the joints must be additionally glued with PVA, otherwise the structure will be weak.

If you make frames for bees yourself from coniferous wood, it is advisable to treat them with drying oil or molten paraffin. The coating will protect the honeycomb from the resin released from the wood. When the frame is assembled, tighten the wire.

The video tells more about the production of equipment:

Wire arrangement on the frame

The wire is pulled onto the frame in rows. There are two patterns for stretching it: longitudinal and transverse.

How to choose wire for frames

The wire is pulled like a string. This state can only be achieved with high-quality materials. Special beekeeping wire is made of carbon steel and sold in coils.

Stores may offer ferrous wire and stainless steel. The first option is cheaper, but is susceptible to corrosion. Stainless steel is considered ideal. Some beekeepers use tungsten wire for tensioning. The result is good, since tungsten is resistant to corrosion. Wires made of non-ferrous metals or fishing line are not suitable for tensioning. They are soft and tend to stretch, which will cause the strings to sag.

Which winding is better: longitudinal or transverse

It is impossible to choose the ideal winding scheme, since each has its own pros and cons. When the strings are stretched transversely, the number of rows increases. The tension force is distributed more evenly across the slats, causing them to bend less. During longitudinal stretching, from 2 to 4 rows are pulled onto the frame, which depends on its size. The tension force is distributed over a smaller area of the slats, and they bend more strongly.

However, it is more difficult to build foundation on a transverse tension. Due to the smaller number of rows of strings in the longitudinal pattern, the process of soldering the honeycomb is simplified.

To select the optimal winding pattern, the strength of the strips and the size of the frame are taken into account. The last parameter is important. For a larger frame, the number of tensions increases.

When choosing one of the schemes, you need to take into account that during operation, even the most taut string weakens. It is advisable not to wrap the ends of the string around a stretched track. They are tied to nails driven into opposite slats. The caps protrude about 5 mm above the surface of the rail. The total length of the nail is 15 mm. It is advisable to take 1.5 mm in thickness. A thick nail will split the plank.

During winding, the ends of the tensioned wire are wound around nails.When the strings sag during operation, tension is carried out by driving a nail. Sometimes beekeepers immediately stretch the wire onto new frames using this method if there is no tensioning machine.

How long will the wire be needed for a rectangular frame?

The length of the wire is calculated using the frame perimeter formula. For example, the length is 25 cm and the width is 20 cm. According to the formula for calculating the perimeter, they solve the simplest problem: 2x(25+20) =90. Structures measuring 25x20 cm will require 90 cm of wire. To be sure, you can make a small reserve.

How to string strings on bee frames

The wire tensioning process consists of 5 steps:

- Depending on the chosen winding pattern, holes are drilled on the side rails or the top and bottom bars. A template or hole punch will help simplify the task.

- Drive one tension nail into each of the opposite planks.

- The wire is pulled through the holes like a snake.

- First, wrap one end of the wire around the nail.

- The free end of the string is tensioned and only then is its end wound around the second tension nail.

The tension force is determined by the sound of the string. A wire held with your finger should make the sound of a guitar. If it is dull or absent, the strings are re-strung.

Tools for making hive frames

When it is necessary to organize the production of frames for hives or the farm has a large apiary, it is optimal to acquire a special machine - a conductor. The device is a rectangular box without a bottom or a lid. Along the perimeter, the internal size of the template is equal to the dimensions of the frame. The higher the walls of the conductor, the more inventory you can make for the hive at one time.

Beekeepers usually make a wooden template from boards.Holes are cut in the opposite walls and bars are inserted. They will be a stop for the assembled side strips of the frames. A gap is left between the bars and the walls of the conductor. Its size is equal to the thickness of the strip plus 1 mm for free entry of the workpiece.

It is important to allow for a margin of clearance when calculating the size of the conductor. Usually 10 frames are inserted into the template. The width of the side strip is 37 mm. In order for the required number of frames to fit into the template in width, 10 is multiplied by 37, plus 3 mm of clearance margin. The resulting machine width is 373 mm. The length of the template corresponds to the width of the frames. For Ruta and Dadan hives the parameter is 435 mm. The top and bottom frame strips remain outside the template during assembly.

The assembly of equipment for hives begins with the insertion of side strips with eyes into the gap between the bars and the walls of the conductor. First, only the top or bottom slats are taken. The blanks are placed in the eyelets of the side planks and fastened with nails or self-tapping screws. The machine is turned over and similar actions are repeated on the other side. When all the structures for the hives have been assembled, they are removed from the template, but first the fixing bars are pulled out.

A metal machine for beehive frames is welded from a square pipe. The design is almost identical, only bolts are used to clamp the workpieces. In addition, there is no need to cut out eyelets in the side rails and bars. Once the upper part of the frame is assembled, the bolt is released, the mechanism is moved down and clamped again. The bottom bar is inserted with force, like a spacer. The elements are connected with a pneumatic construction stapler.

Options for the correct placement of frames in the hive

The number of hundred frames in a hive depends on its size. In addition, they take into account how many sections the house consists of.Nesting frames for brood are always placed in the center. In single-tier horizontal hives they are installed in one row. Inside multi-tiered vertical hives, nesting honeycomb frames are placed one above the other. The side frames and all those that stand in the upper stores of the hive are used for honey.

Inside the hive, honeycomb frames are arranged from north to south. The side slats face the entrance. This scheme is called cold drift. The house is turned north by the entrance. There is a method of warm drift, when honeycomb frames inside the hive are placed parallel to the entrance.

Warm drift has many advantages:

- during wintering in each hive, the death of bees is reduced to 28%;

- the queen uniformly sows the cells, the brood increases;

- the threat of a draft is eliminated inside the hive;

- Bees build honeycombs faster.

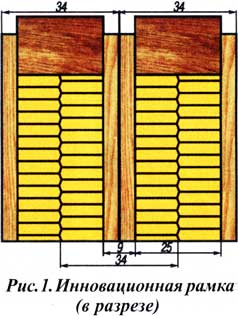

Production of innovative frames for bees

Modern innovative frameworks are not yet particularly popular. Beekeepers are wary of plastic. The technology was developed after conducting high-tech experiments. For a long time it was believed that the optimal passage for a bee between combs was 12 mm. However, using laser measurements, it was established that in natural conditions the gap does not exceed 9 mm. Wooden frames used in beehives for many years distort natural standards.

The innovative model was released with narrowed side strips 34 mm wide. When installing them in the hive, the natural gap of 9 mm is maintained.The advantage of the innovative model was immediately visible by normalizing the temperature inside the hive and improving natural ventilation.

Conclusion

Beehive frames are considered the second most important apiary equipment. The peace and development of the bee colony and the amount of honey collected depend on their quality.