Content

When installing drainage, a special filter material is used - geotextiles. Strong and environmentally friendly fabric belongs to the group of geosynthetics. The main purpose of the material is to separate soil layers of different composition and purpose. The fabric prevents them from mixing, but at the same time allows water to pass through it. Several types of such material are produced. We will now figure out what geotextiles are needed for drainage.

Application of geotextiles

Geotextiles can be called a filter. By allowing moisture to pass through, but preventing the passage of solid particles, the fabric prevents heterogeneous layers of soil from mixing. Thanks to these properties, the canvas is widely used in the construction of drainage systems. They help drain rain and melt water from buildings, sidewalks and other structures.

In addition to the filtration function, geotextiles prevent germination weed. If the canvas is placed under the decorative layer of a bulk garden path, then water will never accumulate on it and weeds will never grow on it. It is necessary to take into account that there are different types of drainage systems, therefore the choice of the type of geotextile occurs on an individual basis.

Type of canvas

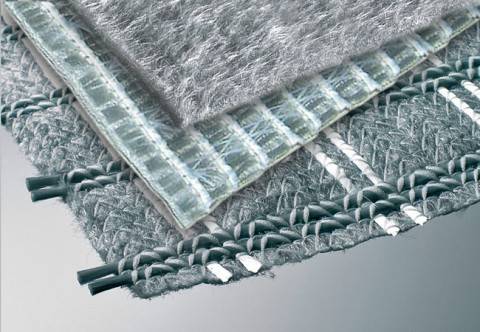

The appearance of geotextiles resembles fabric. But its properties are completely different. The fabric is durable, highly resistant to loads and mechanical stress.

There are two main types of geotextiles:

- The woven fabric is called geofabric. The material is produced from natural or synthetic raw materials by interweaving fibers. The main purpose of geofabric is soil reinforcement. The canvas is covered on large slopes to prevent landslides, and is used in the manufacture of geocontainers and other similar structures.

- The non-woven material is called geofabric. It is made entirely from synthetic raw materials by combining polymer fibers. Geotextile is used in the construction of drainage systems.

Today we are looking at what kind of geotextile is needed for drainage, so we will dwell on the geotextile in detail. There are three ways to produce filter media:

- With the thermal production method, polypropylene threads are welded together.

- The chemical method is based on gluing synthetic fibers.

- The mechanical or needle-punched method is based on the interweaving of synthetic threads or fibers.

Geo-textiles produced by only one of the methods considered are rarely put on sale. Typically, this type of geotextile is produced using several polymers. In this case, a combination is used, for example, of chemical and mechanical methods.

Which geotextiles can and cannot be used for drainage

First, let's figure out what material cannot be used for drainage:

- A drainage material such as thermally produced geotextile will not be suitable. The soldering of the threads is so strong that the material practically does not allow water to pass through. The material is very dense, but it cannot be used instead of waterproofing.

- For drainage, you cannot choose geotextiles that contain natural fibers, for example, cotton or wool. Such fabric will rot in dampness.

- The material, made from polyester threads, is highly durable and resistant to rotting. However, such geotextiles perfectly absorb water, but do not give it away, but keep it in themselves. This type of fabric is not suitable for drainage.

A geo-fabric made from polypropylene threads is optimal for drainage. The fabric is characterized by increased strength, excellent moisture permeability, and resistance to rotting and chemicals.

What parameters are used to choose a drainage fabric?

When considering how to choose a material for arranging drainage, you must first pay attention to how thick it is. A thin fabric will break through during soil movement, and a thick fabric will quickly silt, which will stop the filtration process. It is optimal when the geotextile used for drainage is of medium thickness.

Now let's look at the main parameters according to which the selected material is suitable for drainage:

- Let's start with the fact that for drainage, the density of geotextiles must be selected based on the depth to which it will be buried. It is also important to consider the type of soil. For example, when arranging shallow drainage, it is enough to use a fabric with a density of 150 g/m3. On low-moving soils, when laying drainage pipes, use material with a density of 200 g/m3. Where there is seasonal ground movement, a fabric with a density of at least 300 g/m is suitable3.

- For drainage, you only need to lay geotextiles that have high moisture permeability characteristics. This type of material includes a geo-fabric made of polypropylene threads.

- There is such an indicator as the filtration coefficient. It indicates the volume of moisture that the geotextile can filter per day. For drainage system, a minimum value of 300 m is allowed3/day.

- In order for the laid geotextile to serve for a long time, it is necessary to optimally select the material for mechanical strength. For drainage, a fabric with a transverse tensile load of 1.5–2.4 kN/m, and a longitudinal tensile load of 1.9 to 3 kN/m is used.

Often the geotextile for drainage systems is simply determined by its white color.

Rules for using geotextile when arranging drainage

Laying the geo-fabric is very simple, since the canvas is easily cut with a knife and rolled up to take the desired shape. To achieve effective drainage, you need to follow simple rules:

- Being exposed to the heat for a long time under the sun, the geo-fabric can deteriorate its filtering qualities. It is optimal to unpack the material immediately before use and immediately cover it with soil.

- To prevent the canvas from tearing, it must be laid in the trench after leveling the bottom and side walls. The fabric should not be too stretched and without folds. If a hole has formed on the geo-fabric, this piece must be cut off and then replaced with a new one.

- The width of the canvas is selected so that it can overlap the pipe with drainage filling.Here you need to make calculations before installing the drainage system. The cross-section of the pipe, as well as the thickness of the fill, are taken into account. Ideally, drainage is obtained if it is enough to roll out a single piece of geotextile along the trench.

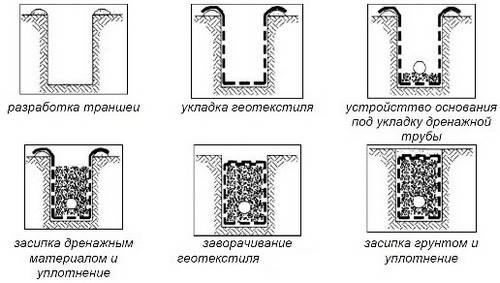

- To have a better idea of laying the geofabric, let's take a closer look at the drainage arrangement scheme. So, a cloth is spread at the bottom of the trench. Its edges should extend beyond the pit, where they are temporarily pressed with a load. Crushed stone about 300 mm thick is poured on top of the geotextile. Next, the pipe is laid and backfilled with a similar layer of crushed stone. After this, the free edges of the geotextile are overlapped around the entire filter system. Finally, the trench is backfilled with soil.

If the laying of the crushed stone geotextile and pipes was done correctly, the drainage system will function properly for many years.

The video talks about geotextiles:

Selecting suitable geotextiles for drainage installation is not difficult. As a last resort, you can use the recommendations of sellers. The main thing is to strictly follow the technology of laying the material.