Content

The traditional place for growing seedlings is the windowsill. Boxes here no one is disturbed, and the plants receive daylight. The inconvenience of this method is due to space limitations. Few seedlings fit on the windowsill. The floor is not the best place. To grow a large amount of planting material, racks for seedlings with lighting are made, installed against the wall near the window or on the windowsill.

Varieties

Easier to purchase seedling rack in the shop. However, the cost of the product is high, and the quality is not always good. The shaky structure can collapse at any moment. It’s easier to make a rack yourself according to individual dimensions, but first you need to decide on the design.

Stationary

A stationary rack for seedlings usually holds 5 shelves and is installed on the floor. The design is not collapsible. For reliability, the rack is fixed to the wall and floor. The model is suitable for people who are constantly growing planting material in large quantities.Due to the impossibility of disassembling the structure, it will be necessary to find an empty room for installation. Dimensions are calculated individually. The optimal material for manufacturing is wood.

Collapsible

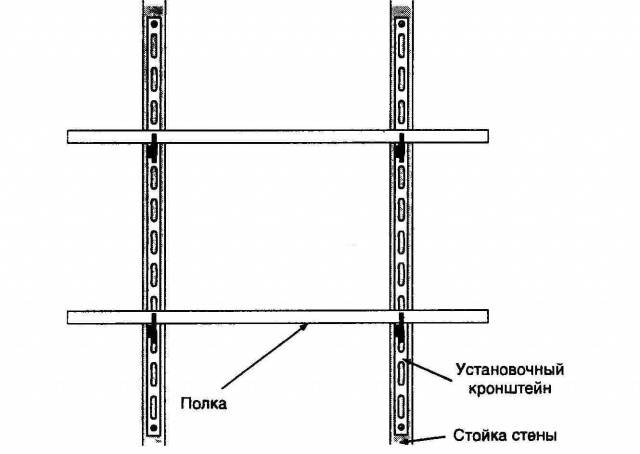

The most convenient to use is considered to be a collapsible rack. The design can consist of 3, 4 or 5 removable shelves, installed as needed. The manufacturing material is a thin-walled metal profile with a galvanized coating. The collapsible model is installed while growing seedlings, and then it is stored in a shed.

Window

The window rack for seedlings accommodates 3 shelves due to the height limitation of the opening. The width of the windows is also different, so it is better to make such structures yourself with individual sizes. The height distance between the shelves is maintained at a maximum of 50 cm. The rack can be made folding or non-collapsible, but the first option is better. After growing the planting material, the structure is dismantled for storage until the next season.

With case

On sale you can find a rack for seedlings with a cover, consisting of 4-5 shelves. A similar design can be made at home. The manufacturing material is a thin-walled pipe with a diameter of 15 mm, an angle or a profile. The cover is sewn from transparent film or agrofibre. The purpose of the shelter is to create a microclimate for seedlings. The cover forms a mini-greenhouse, which allows you to install the rack in a cool room.

Firstly, lamps will become a source of heating for plants in a cool room. Secondly, the shelter partially reduces the intensity of daylight coming from the window and without artificial lighting the seedlings will be dark.

Materials for making your own structure

The basis of the rack is the frame. The racks and lintels bear the entire load from the shelves and boxes with planting material. The structure is assembled from a wooden beam, a metal corner, a pipe or a profile.

Shelves are similarly subject to heavy loads of earth boxes. The material for manufacturing is any high-strength sheet material: multi-layer plywood, iron, chipboard or other boards. Build shelves from scrap boards. When using any material, covering with film will be required. When watering seedlings, water gets onto the shelves. When damp, wood begins to rot and metal begins to rust.

The nuances of self-production

Having decided to assemble a rack for seedlings with your own hands, you need to think through all the nuances in advance:

- the size depends on the free space where the structure is supposed to be installed, and also takes into account the number of seedlings grown;

- The material is selected from what is available at home, but strength and resistance to moisture are taken into account.

Having decided on the materials and dimensions, a design drawing is drawn up. The diagram shows mounting locations for backlight lamps.

The video shows the assembly of the rack:

Wooden stand for windowsill

The simplest window sill rack for seedlings will be made from wooden blocks with a cross-section of 30x30 mm. Thick tempered glass or multi-layer plywood are suitable for shelves. The size of the structure depends on the dimensions of the window opening and the width of the window sill. There should be a gap of at least 5 cm between the shelving and the side walls of the opening.

The height of the window usually allows for 3 shelves. The distance between them is at least 50 cm. A similar gap is provided between the top shelf and the wall of the window opening.

To make a frame from timber, 4 racks, 6 long and 6 short lintels are cut. The blanks are connected with self-tapping screws. To strengthen the corners, it is advisable to use overhead metal plates. The assembled rack for seedlings on the window is treated with protective impregnation and opened with varnish. Shelves are placed on the lintels and lamp mounts are fitted.

Stationary timber structure

Stationary home racks for seedlings are most often also assembled from timber, only the blanks are used with a larger cross-section - 50x50 mm. Manufacturing instructions consist of the following steps:

- According to the dimensions of the drawn up drawing, blanks are cut from the timber. Stationary racks for growing seedlings are made with five shelves. You will need 10 long and 10 short jumpers. 4 pieces of racks for the frame are enough. If you make a rack longer than 2 m, it is advisable to place a couple of additional supports in the middle. The racks will prevent the long lintels with shelves from bending under the weight of the boxes with seedlings.

- On the racks, mark the locations of the jumpers with a pencil. The workpieces are connected with self-tapping screws and overhead mounting angles made of metal must be used.

- The assembled frame is installed in a permanent place.For better stability, the rack is fixed at several points to the wall.

Shelves are cut out from plywood or made from boards. All wooden elements of the rack are impregnated with antiseptic. After the impregnation has dried, you can open it with varnish.

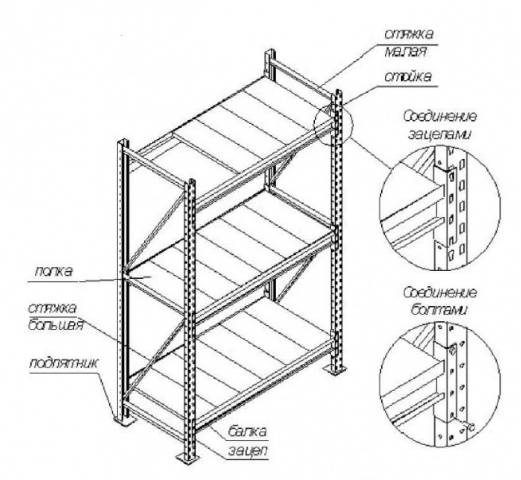

Five-tier metal structure

You can make a metal rack for seedlings in a collapsible or stationary type. It is better to make a folding structure from a corner. Holes are drilled in the workpieces for bolted connections.

A stationary rack for seedlings is made of a pipe or profile. The workpieces are joined by welding.

The finished metal structure is painted. The steel rack is stable due to its weight. If you have doubts about the quality of your assembly, it is better to provide additional fastening to the wall or floor.

Backlight options

When making a rack for seedlings with your own hands with lighting, you need to choose the right lamps. Not every light source has a beneficial effect on plant development. The following lighting options are available:

- Traditional incandescent lamps are the worst lighting for any seedlings. The only plus is the low cost. The lamp emits little light, but gives off a lot of heat, which is dangerous for young plants. Another disadvantage is the high energy consumption.

- Low-power fluorescent lamps emit light up to 100 Lm/W. A good option for seedlings, but not enough red radiation. The light is too cold.

- LEDs are great for illuminating planting material on racks. The stores have a large selection of lamps, lanterns, and ribbons. You can choose a light source of any configuration. LEDs emit maximum light of a different spectrum and minimum heat.

- Metal halide lamps are considered economical and efficient.They emit light up to 100 Lm/W. The disadvantage is the lack of blue spectrum.

- Up to 200 Lm/W of yellow light is emitted by gas-discharge lamps. To make them work you will need to buy a regulator.

- Ordinary daylight is emitted by mercury lamps.

- Excellent results are shown by racks with phytolamps for seedlings, providing plants with the most comfortable conditions for growth. The light source will not burn the leaves even at maximum proximity. Phytolamps are economical, environmentally friendly, and their glow has all the spectrums that seedlings need.

There are xenon, halogen and other lamps, but they are rarely used for seedlings.

Making your own LED backlight

When considering how to make a rack for seedlings with lighting, it is worth focusing on LEDs. It is advisable to avoid lamps, as they emit a limited spectrum. Red and blue glow strips work well for homemade lighting.

The basis of a homemade lamp will be a wooden beam. The length of the workpiece and the shelf must match. Two aluminum profiles are screwed parallel to the beam. They are needed to remove heat from the LEDs. The LED strip has an adhesive base on the back side. A blue tape is glued to one profile, and a red tape to the other. The backlight will work from the power supply. The finished timber lamp is suspended above the seedlings, secured with a rope to the lintels of the rack.

Plants need their own microclimate, so humidity is always present, especially after watering or spraying. Having decided to make a rack with lighting for growing seedlings, we must remember about electrical safety.