Content

Planting potatoes is a rather labor-intensive process. And while a small garden can be managed manually, it is very difficult to plant a large area without the use of machinery. A walk-behind tractor has now become an indispensable assistant to a gardener. But the unit itself only provides traction force, and to perform any tasks you also need to have a tow hitch. One of these mechanisms is a potato planter for a walk-behind tractor, which allows you to automate the planting process.

Construction and operation of a potato planter

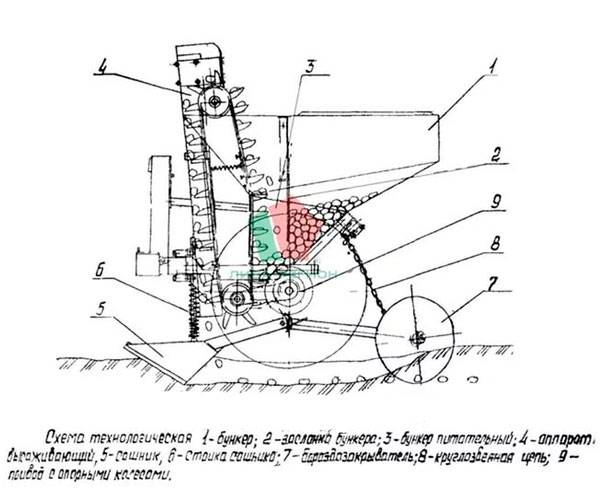

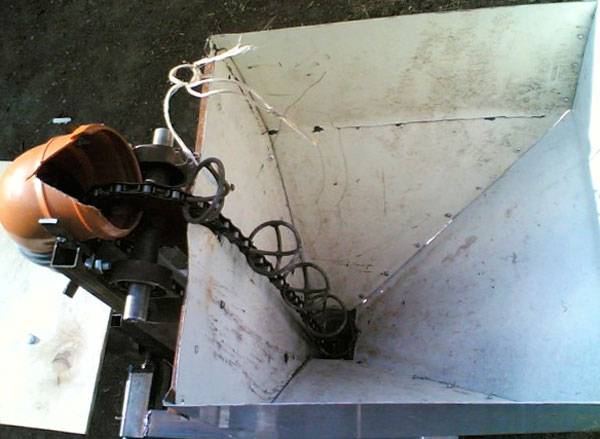

So, a potato planter is a towed device to a walk-behind tractor or mini-tractor. While the unit is moving, a chain mechanism with bowls automatically grabs potato tubers from the hopper and feeds them into the holes. A plow is installed under the frame of the walk-behind planter. He is responsible for cutting the furrow.

At the end of the potato planter frame, two disks are installed at an angle. After feeding the tuber, they fill the furrow with soil. To ensure that the potatoes fall into the hole evenly, the bowls are mounted on a chain mechanism at the same distance.The size of the towbar and the volume of the planting hopper are selected individually, taking into account the power of the walk-behind tractor or mini-tractor.

The design of a homemade potato planter consists of the following main parts:

- The frame is the basis of the tow hitch. It is welded from a profile pipe. Why is this particular material used? The square cross-section gives strength to the pipe, while it remains quite light. In addition, it is easier to attach potato planter parts to a flat profile wall than to a round pipe. All working units are fixed to the frame, and the bow part is equipped with a device with the help of which the planter is coupled to the walk-behind tractor.

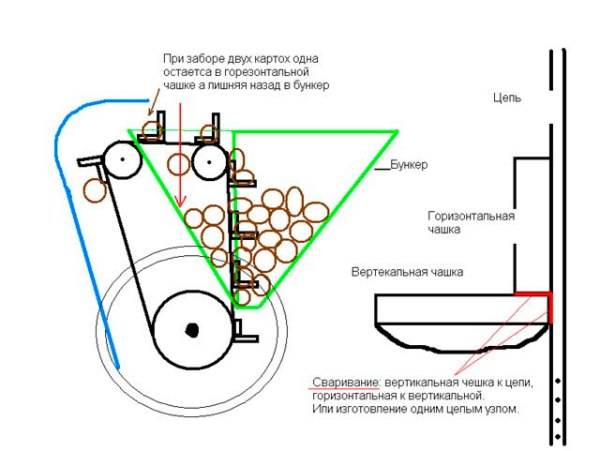

- The hopper is a cone-shaped container for loading potatoes. The choice of this form is not accidental. In many photos you can see homemade bins from a stainless steel washing machine tank. The option is not bad, but during planting there may be missing empty areas of the furrow. In a cone-shaped hopper, the potatoes constantly settle to the bottom, which allows the tubers to be captured by the bowls, even if they are left alone. The bottom of the washing machine tank is sloped, but it is not enough to ensure a secure grip until the last potato.

- The chain mechanism operates on the principle of a conveyor. It is driven by a sprocket attached to the wheel shaft. A second sprocket is installed on top behind the rear wall of the hopper to tension the mechanism. The conveyor is usually made from a bicycle or motorcycle chain. Wire bowls are welded to its links at equal distances.

- The plow is secured under the frame and located directly in front of the chain mechanism. He cuts a furrow before the potato even falls out of the bowl.

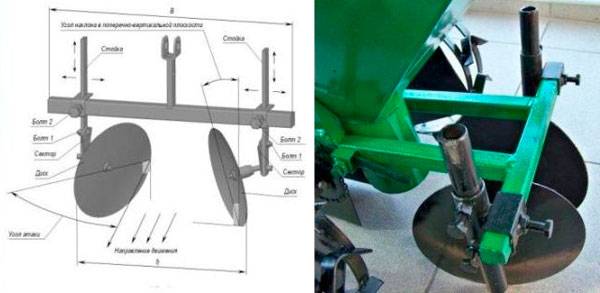

- Two discs mounted at an angle on the rear of the frame form a harrow. They fill up the tubers that have fallen into the hole.

That's the whole device of the potato planter. Such a simple mechanism will allow you to quickly plant your garden using a walk-behind tractor.

Potato digger drawings

We invite you to look at the hand-made drawings of the dimensions of the walk-behind potato planter, which will help in the further design of the tow hitch.

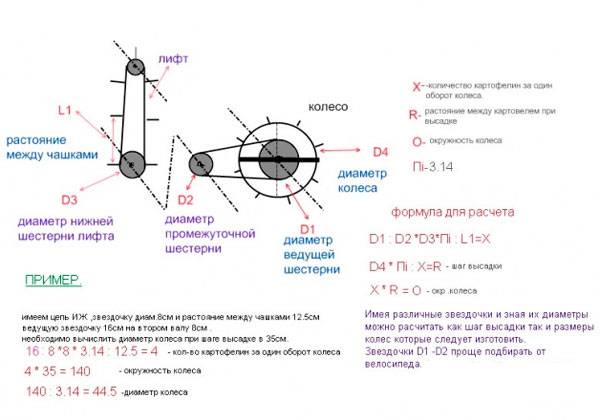

The following photo shows the calculation of a chain mechanism with sprockets.

Instructions for making a homemade potato planter

Let's look at the procedure for making a potato planter for a walk-behind tractor with your own hands:

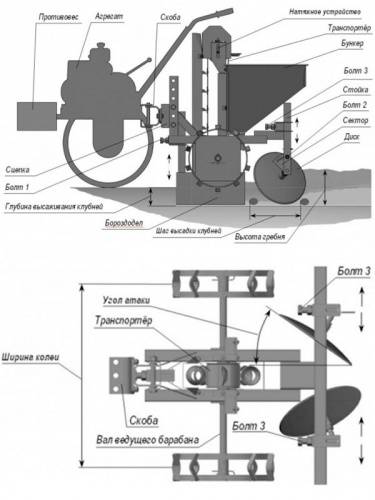

- First you need to weld a strong frame from a profile pipe. A hitch is welded in front to connect to the walk-behind tractor, as well as two conveyor posts. Fasteners for disks are welded to the rear of the frame.

- Fasteners are welded under the frame, that is, on its lower side, to secure the plow. The bearing races, which will be mounted on the shaft with the drive sprocket, are also attached here.

- Assembling the shaft begins with installing the sprocket. It can be fixed to the key by tightening it with nuts on both sides. It’s easier to weld the star, but this design will not be dismountable. If the teeth break off, the sprocket will have to be cut off with a grinder or cutter. Next, bearings are mounted on the shaft and the structure is installed in prepared cages. The wheel hub is attached to the ends of the shaft. To prevent the bearings with the shaft from leaving the cages while the walk-behind tractor is moving, bolt two stoppers made of a metal corner to the frame.

- Now let's start making bowls to capture potatoes from the hopper. To do this, a ring with a diameter of 60 mm is bent from steel wire with a cross-section of 6 mm. The wire joint must be welded. Curved bridges are welded crosswise at the bottom of the bowl so that the small tuber does not fall through the ring.

- The number of bowls is calculated so that the tubers fall into the furrow every 25–30 cm. This is done empirically, since everything depends on the diameter of the sprockets and the length of the chain. The finished bowls are welded at equal distances to the chain links.

- Hubs are attached to two conveyor posts welded to the front of the frame and a shaft with a tension sprocket is installed, after which the chain is put on. To tension it, the front posts of the conveyor can be made of two parts with a bolted connection. When lifting the upper parts of the racks, the chain will tighten, after which you need to secure them with bolts.

- Now let's start making the bunker. The chain will interfere, so it is temporarily removed. The bunker is cut out of sheet steel. You should get a cone-shaped quadrangular container as in the photo. Please note that one of the walls on the chain side is not made at an angle, but strictly vertical. This design allows the conveyor to work better.

- When the bunker is ready, install the chain in its place. Now we need to fine-tune the mechanism. First, tighten the chain, then scroll it, making sure that the conveyor does not catch the edges of the container. When the optimal location of the bunker is found, it is firmly fixed.

- A chute must be installed behind the hopper. It will direct the falling potatoes from the conveyor bowl exactly into the hole. The gutter can be made from tin or PVC sewer pipe with a diameter of 110 mm.

- Finally, the discs are attached to the rear of the frame.It is imperative to make a mechanism that allows you to change the angle of their inclination and rotation.

At this point, the potato planter for the walk-behind tractor is ready. You can install drive wheels and try to roll it around the garden.

Potato digger seat

Walking behind a walk-behind tractor across a large field is very tiring. Resourceful owners of walk-behind tractors will improve potato diggers so that they can sit on them. To do this, an elongated frame is made, and racks with jumpers are welded to it from the profile, forming a seat. Of course, it will be more convenient to lean on the back, but you can do without it.

Wheel design features

Regular wheels are not suitable for a potato planter. You need to take metal discs and weld lugs on them. There are many options. For example, you can simply weld pieces of steel angle across, bend angles from a plate, weld spikes from rods, etc.

Video of a homemade potato planter:

Without skills in working with metal, it is difficult to make a potato planter yourself. But if the hands grow from the right place, a homemade design will significantly save your home budget.