Content

- 1 Why does a beekeeper need a table for printing honeycombs?

- 2 Types of bee tables and devices

- 3 How to make a machine for printing honeycomb frames with your own hands

- 4 Is it possible to make a Kuzina cultivator yourself for printing honeycombs?

- 5 How to operate a honeycomb frame printing machine

- 6 Conclusion

A table for printing frames helps the beekeeper speed up and facilitate the process of pumping out honey. It is more convenient to print the honeycombs on the machine before placing them in the honey extractor. The design of tables often differs in size. Each beekeeper tries to select equipment according to his needs.

Why does a beekeeper need a table for printing honeycombs?

Honeycombs are made up of cells where bees collect and process nectar. Ripe honey is sealed with caps - a cap. They consist of three components: honey, propolis and wax. The lids prevent honey from leaking out of the honeycomb cells. To pump out the product, the beekeeper has to cut the bar. Only after printing is the frame placed in the honey extractor.

Printing a frame is labor-intensive. Wax honeycomb is viscous. It is difficult to cut timber without special tools. When processing a small number of frames, beekeepers make do with apiary knives, cultivators, and forks. For a large apiary, you need a machine for printing honeycomb frames to help speed up the process.

In its homemade version, the device is a table. It is beneficial for medium-sized apiaries. It is made of metal or wood. The main element is a trough with a basket, a wooden cross member and a needle. Everything is fixed to the frame. The bottom of the trough is made with a slope to allow honey to drain. A drain valve is fixed at the bottom point. The basket collects timber cut from the honeycombs. The needle serves as a holder for the frame.

Industrial tables are equipped with a conveyor, electric drive and other devices. There are automatic machines. On industrial tables, printing is often done with a hot wire. The string is heated by electricity.

Types of bee tables and devices

Many devices have been invented for printing honeycomb frames. They all differ in design, but the main difference is the principle of operation. It is according to the last parameter that beekeeping devices are divided into 3 types:

- Cutting devices remove the bar, capturing a small amount of honey with wax cells of the comb. Cut off caps after printing require further processing. To separate the wax from the honey from the bark, the beekeeper needs to purchase additional equipment.

- The cutting devices do not remove the bar during unsealing. On the honeycombs the caps are cut. Pure honey flows out through longitudinal slits. However, cutting machines are not in demand by beekeepers due to their imperfections. The advantage is the absence of wax in the flowing honey. Bees restore cut honeycombs faster. This group includes machines with brushes and chains. However, they have even more disadvantages.After passing over the caps, the brushes and chains not only cut the bar, but also clean the wax from the combs.

- Piercing devices consist of many needles. The bristles pierce the lids of the combs, squeezing honey out of them.

If we talk specifically about each device, then printing honeycombs in amateur apiaries is performed with the following tools:

Apiary knives are ordinary, heated in hot water before cutting off the caps. The downside of the tool is considered to be low productivity, water getting into the honey frame. Electric and steam knives are improved. The first instrument heats up when connected to a 220-volt power supply through a 12-volt step-down transformer. A car battery is also used. The steam knife is heated by the steam generator.

A popular tool among beekeepers is a honeycomb fork and a needle roller. The first device clears the timber. The advantage is that there is no need to warm up the fork before use. Needle rollers pierce the caps without removing the lining from the combs. The tool is made of plastic or metal.

An electrically powered wood cutter resembles a mixture of an apiary knife and a carpenter's plane. During operation, the device cuts off the beam. Connect the cutter to a 220 volt network.

Amateur beekeepers use a hair dryer and a gas burner to process a small number of frames. The process is based on heating the casting with a stream of hot air. The downside is the flow of melted wax from the top of the honeycomb onto the lower cells.

To make printing of honeycomb frames with any tool faster and more convenient, tables and all kinds of stands are used. The frame with honey is fixed at the optimal height.The beekeeper prints the combs without worrying about the frame. The cut caps will fall into a special table tray.

How to make a machine for printing honeycomb frames with your own hands

It’s not difficult to build a machine for printing frames. It is important to know what parts it consists of:

- The basis is a frame made of wood or metal. Sometimes it is immediately made in the form of a box with legs.

- The frame holder is a support.

- A metal tray is installed on the bottom of the frame or the bottom of the box. Honey will flow into the container.

- A basket for collecting pieces of wax and caps is made of fine mesh.

- The metal tray of the bee table is equipped with a drain valve.

The size of the table for printing frames with your own hands is made by the beekeeper at his own discretion. There are no special requirements here.

Drawings, tools, materials

The table drawing is shown in the photo. There is nothing complicated in the design. The manufacturing material is wood and stainless metal. Aluminum will do. You will need a standard set of tools:

- saw:

- drill;

- Bulgarian;

- hammer;

- pliers;

- screwdriver.

If you make a steel frame with legs for the machine, you will need a welding machine.

Build process

The easiest way to assemble a bee table with your own hands is from wood, but you can use a ready-made tank from old household appliances. The process consists of the following steps:

- A wooden table is made from timber and boards. The height of the legs is made such that the operator does not constantly stand in a bent state. The width of the structure must correspond to the size of the frame. There are no restrictions on length. The machine is made without a cover. Instead, one part is occupied by frame holders. A cross beam is attached to the second part of the table. A container for collecting honey is placed on it.The pallet must be made of stainless steel or aluminum.

- A comfortable table is made from a stainless round washing machine tub. The bottom of the container is already made at a slope. There is a drain pipe at the bottom point. It is cut off with a grinder. A drain valve is inserted into the hole. The table is supported by metal legs. The frame is welded from a rod 10-12 mm thick.

- When the frames are printed, honey will flow out of the honeycombs. It must be separated from the wax. The filter is a metal mesh with cells measuring 3 mm. There are supports for her on the table. The mesh is stretched over a frame made of slats. The element is made removable. The frame holders are ordinary wooden slats fixed across the table.

- The final assembly of the table intended for printing frames is the installation of a drain valve on the honey collection container. Ball valves are used. It is fixed in the table tank with a threaded adapter with nuts.

Beekeepers do not recommend making a table that is too long. The inventory will need to be stored somewhere. It is important to maintain the width so that the frame fits.

The video shows an example of a bee table:

Is it possible to make a Kuzina cultivator yourself for printing honeycombs?

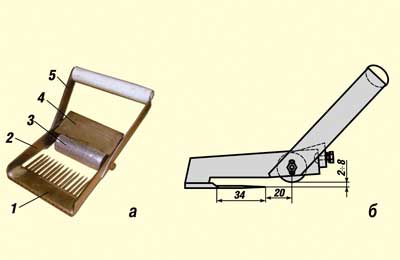

Popular among beekeepers is a honeycomb unsealer called the “Kuzina” cultivator. The device is convenient to use when printing winter frames. The tool consists of a frame. On one side there are teeth attached, forming a comb or fork. There is a handle attached to the opposite side. In the diagram, number 3 indicates a limiter pressed by elastic plate 4. The elements limit the penetration of the fork into the frame.

The cultivator bed for printing honeycombs is made of stainless steel 1 mm thick. A U-shaped blank is cut 18 mm wide and 75 mm long. For a fork, take a steel plate and bend it in half. Sewing needles No. 7 are inserted between the strips. The plates are clamped with a clamp and soldered at both ends so that they do not separate and hold the needle firmly.

The limiter roller is cut from a piece of aluminum tube with a diameter of 22 mm and a length of 58 mm. A rubber hose with a thin tube with a diameter of 4 mm is pressed inside, forming a channel for the axle. The pressure plate is cut out of stainless steel 1 mm thick and fixed with a bolt to the frame. A handle is cut out of similar metal. In relation to the bed it is fixed at an angle of 50 O. The rotation of the limit roller occurs on a pin, which allows you to adjust the depth of immersion of the fork into the honeycomb during printing.

How to operate a honeycomb frame printing machine

The process of printing honey frames depends on the device used. The table is only a support for the frames.

How to print honeycombs for pumping out honey

To print the combs, the frame is placed in the table holder. Use a fork, knife, cultivator or other device to remove the timber. The lids fall and remain on the table filter mesh. The honey flows into a tray with a drain tap. Upon completion of work, the removable elements of the table are disassembled and washed with hot water.

Conclusion

The table for printing frames is made stable, light and compact. The equipment will be stored in a shed or attic most of the time. It is more convenient if the table is collapsible or partially foldable.