Content

Bee smokers are used by beekeepers during hive maintenance. Plumes of smoke calm aggressive insects without harming them. The design of the smoker is so simple that you can make it yourself. Improved models are purchased at specialized retail outlets.

What is a smoker and why is it needed?

Essentially, a smoker is a metal container, usually in the shape of a cylinder with a spout. The device of the simplest design has three components:

- Double-layer metal body. Stainless steel is considered the best material for production.

- The lid is in the shape of a cone-shaped spout. Depending on the model, the element is removable or tilts to the side from the body.

- The bellows supply air inside the housing to maintain fuel combustion.

The double body of the device forms a firebox. The internal second element is a similar part, only smaller in size and with a mesh bottom. This is where fuel smoldering occurs. Due to the absence of contact of the main body with heat, the outer surface of the smoker does not heat up.

The lid with a long spout is convenient for supplying smoke to the frames and into the tap hole. The bellows are a mechanical pump that supplies air inside the firebox.With each pumping, the heat swells, and a thick portion of smoke comes out of the spout.

The calming effect is due to the special effect of smoke on insects. The bees are afraid of him. When smoke appears, they collect a goiter full of honey. The heavy load prevents the bee from bending. The insect becomes clumsy and calmly moves around the frames and body of the hive. At this time, the beekeeper inspects the frames, maintains them, and pumps out honey. Smoke cannot guarantee 100% protection from bees. A few insects will still sting the beekeeper, but the main swarm will not interfere with the work.

Varieties of smokers

The operating principle of smokers of different models is the same. The device differs, which affects ease of use. The following types are available to beekeepers:

- An ordinary apiary smoker is the simplest, most reliable, most common, but requires constant manual air pumping. Such work does not always suit beekeepers when they need to serve large families of bees. The factory-made model consists of a body, a hinged lid with a spout, and a loading cup with a lattice bottom. The furs are made of two plywood elements connected by leather. Between the plywood there is a spring that works on compression. Product weight is about 1 kg.

- The model called “Ruta” is identical in design to a simple bee smoker. The difference is the country of issue. The model is widespread in the USA and European countries.

- “Vulcan” is very popular among beekeepers. Compared to previous models, the device is self-acting.At the bottom of the case there is a winding mechanism that drives the fan. The rotating propeller inflates the smoldering fuel with its blades. Additionally, “Vulcan” is equipped with an adjustment lever. The left position is maximum smoke, the right position is minimum smoke.

- The beekeeper's electric smoker is similarly powered by a fan. The device does not need bellows. The fan is powered by a battery installed inside the additional compartment.

“Vulcan” and the electric model are most popular among beekeepers who keep a large number of hives. The devices work practically independently; you just need to add fuel in time.

Is it possible to make a smoker for bees with your own hands?

If there is a desire or need for a smoker with your own hands, it is better to start assembling it with the simplest design. Manufacturing procedure:

- For the body you will need two cylinders, preferably made of stainless steel. The parts must be of different sizes. The diameter of the main body is approximately 100 mm, the height is approximately 250 mm. The sleeve can be cut from a thin-walled pipe and welded with a plug on one side to form the bottom. The second blank is made according to a similar principle, only smaller in size. The smaller cylinder should fit inside the larger glass according to the principle of a folding doll.

- The bottom and side walls of the smaller cylinder are perforated with a drill. 3-4 legs 30 mm high are welded from the bottom so that a gap is formed between the bottoms - a vent.

- The lid of the device for bees is bent from thin steel into the shape of a cone. The diameter of the lower part is selected so that the cap fits onto the body. A fine-mesh steel mesh is fixed inside the lid. The element will play the role of a spark arrester, protecting the bees from burns from the blown fuel.

- A hole is drilled on the lower part of the main body in the area of the blower. Rivets secure the bellows fasteners.

- The furs for the beekeeping smoker themselves are made from two rectangular pieces of plywood. A spring is placed at the top between the blanks. The plywood meets from below. You should get a V-shaped part. They are fastened together with leather, shooting them with staplers to the plywood. A hole for air is cut out in the lower part of the bellows and this part is attached to the prepared fasteners on the body.

The finished smoker is tested in action. If everything works, you can go to the bees.

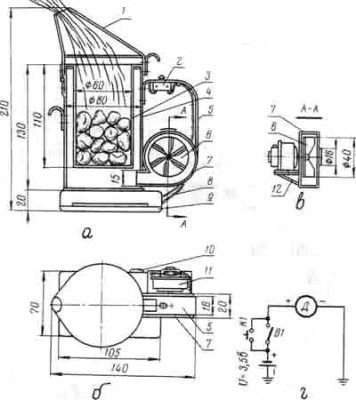

A homemade electric smoker is made according to a similar principle. Only the furs are replaced with a snail with a fan. You can find a toy blower in the store. Instead of a handle, attach a motor from a children's toy. Place the propeller on the rotor shaft. The outlet nozzle of the blower is attached to the place where the hole for the bellows is prepared. In addition to the smoker, a plastic box is attached to serve as a case for batteries.

Which smoker is best for bees?

It is impossible to specifically answer the question about the advantage of this or that smoker. Beekeepers are people of principle. Everyone has their own habits, prejudices, plans. In terms of ease of use, the first place goes to the ordinary beekeeper's smoker.

From a scientific point of view, the electric smoker is not only productive, but also gentle on bees. A constantly running fan is capable of inflating raw fuel. The smoke along with the steam comes out of the spout almost cold, without burning the bees.

“Vulcan” is also not bad, but it requires periodic activation with a key, which is not always convenient. On the other hand, the battery also runs out and has to be replaced.

How to light a smoker correctly

It is not difficult to light a smoker of any design. The main thing is to prepare good fuel the day before the bees visit. The sequence of ignition of an electric device for fumigating bees:

- Remove the ash collector and smoke tube. Use a lighter to light a bunch of splinters and place them in the loading hole. Turn on the fan to fan the fire at low speed.

- After complete ignition, add a small amount of fuel. When there is thick smoke, the bunker is loaded to the top with fuel. Put the tube in place.

- Dry methenamine is placed in the ash collector and set on fire. The fan continues to operate at low speed.

It’s even easier to light a regular beekeeper’s smoker. The inner glass is filled with dry fuel. Set fire to a piece of crumpled paper. The fire is placed on fuel, covered with a lid with a spout, and they begin to fan it intensively with bellows. Air shocks will cause ignition. The fuel will begin to smolder, emitting thick smoke.

The video shows a quick ignition of a smoker for fumigating bees:

How to fill a smoker for bees

Bees do not like acrid smoke. It is necessary to select fuel with this in mind. Ordinary wood, sawdust, dry straw will not work. The fuel must not burn. The sparks will burn the bees. It is optimal to spray the hive with low temperature smoke. A common fuel is rotten wood. Beekeepers collect it on old stumps and fallen trees. The dust emits a soft, non-hot smoke that is comfortable for the bees.

The downside of rotten wood is that it burns quickly. Frequent refilling of the smoker while servicing bees is unprofitable. Dry mushroom can replace rot. The tinder fungus grows on a tree in the form of a solid growth. The mushroom produces smoke much longer and is just as comfortable for bees.

Another type of fuel is oak bark.You can even take a little damp one. The bark smolders for a long time, does not catch fire, and the smoke is comfortable for the bees.

Terms of use

When fumigating bees, they use a smoker in compliance with the following rules:

- Only those frames with bees that need to be removed from the hive for maintenance are fumigated with smoke;

- after opening the hive lid, you should not immediately blow smoke, let the bees calm down;

- when fumigating bees, you should not blow smoke into the nest;

- If possible, the smoker is removed from bees and honeycombs so that hot smoke does not harm them;

- if the smoker is temporarily not needed, it is placed on its side, then inflated again;

- After servicing the bees, all holes in the smoker are closed, and the fuel goes out without access to oxygen.

The body of the smoker is not hot, but warm enough for the bees and honeycombs. Even an extinguished device is placed further from the hive, since it takes a long time to cool down.

Conclusion

The bee smoker should always be kept in good condition. In hot, dry weather, a defective appliance may cause a fire.